Overview

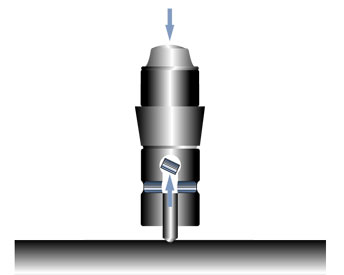

The STE Pin Brinell testers are the first Brinell hardness testers at a low price. The unique impact hardness method uses a shear pin to control the force applied by a hammer, so it significantly reduces the costs of getting started in Brinell testing. The indentation left after a test is measured with a Brinell scope, just like a standard Brinell, so the tester can be used on non-homogeneous metals and as-ground test surfaces. The kit comes with with everything needed for testing (except the hammer and carbide indenter if testing on high hardness materials) and includes a bag of 250 shear pins (one pin is required for each test). This pin system replaces the impact bar system, giving greater versatility, high accuracy and quick, easy indentations that can be made by anyone.