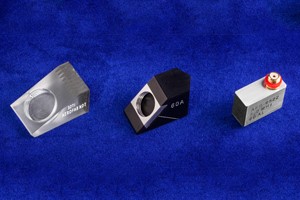

AFFRI LD Series Hardness Testers come in 3 available models:

One Button Automatic Measurements

Press the START button and the measuring head approaches the sample, applies the load to perform the indentation and goes back up; all in automatic succession without breaching a phase. The measuring cycle is a fully motorized electronic system for automatic preloading, loading and measurements. The test cycle is not affected by operator influences and can easily be used by operators of every level.

Load Cell and Closed Loop Technology

Load forces are applied through load cells and electronically controlled in “Closed Loop” with a frequency of 1 kHz. Results are not affected by any structural deflection, misalignment or external vibration. Accurate measurements, even on the first test, eliminate the need for multiple tests. The first test is correct and absolute, saving time and money, increasing output and productivity.

Motorized Vertical Stroke

Fully motorized measuring head with a vertical sliding stroke of 1.2" (30 mm). When testing unstable samples or deflective parts, the measuring head will follow the sample without losing contact, compensating any frame deflection during the test cycle. Accurate results are assured even with oiled, dusty or dirty pieces.

Clamping System

Secure contact with the specimen is always maintained, even in the unlikely event of any specimen movement during the operation cycle. No additional support accessories are required.

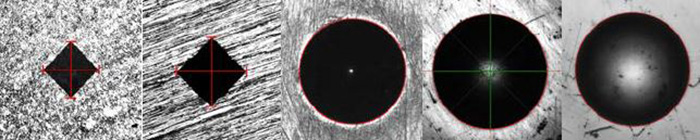

L.I.S.A - Laser Indicator System AFFRI

Exclusive application which allows ultra-precise test positioning. It can reach extreme points with lack of illumination, edges of gear's teeth, or sides of cutting tools and blades.

Protected Indenter

The indenter is protected and retracted, it only moves down after the specimen is fully clamped and stable, minimizing the risk of accidental damages.

Extreme Precision

The synergy between the tester features allows for a correct result even if the piece is badly positioned. The measurement is not compromised if the piece is dirty with oil or dust.

Elevating Working Base

Vertically sliding chromed worktable capable of bearing masses up to 6,600 lbs. (3000 kg) which allows for steady hardness measurements on bulky or irregular pieces.

The LD 3000 A measuring probe is a light and handy system which can work in any direction. The microscope uses a high definition camera for the automatic reading of the indentation diagonals or diameter. It is equipped with a powerful LED light source and has a long-life span.

Easy to Use

Put the test probe on the surface to find the indentation and push the red button on the side of the handle.

Touchscreen and Software

Features a side touchscreen for easy test planning and a clear view of results. It has user friendly Windows® interface and it can store testing sessions in the large memory library using the on-board software database.

Fully Motorized Hardness Tester

The LD 3000 B hardness tester is a fully motorized system for automatic preloading, loading and measurements. It can perform every hardness scale for universal use in your own laboratory. The LD 3000 B performs direct reading for Rockwell and Brinell HBWT up to 3000kgf and can also be used to generate Vickers and Brinell HBW indentation.

Special Model for Case Depth Measurement

The hardness tester LD 3000 B can determine the case hardness depth (CHD). Testing can be performed on a non-metallographic prepared specimen. The system will determine the superficial hardness and its effective depth (CHD), from 0.05 to 0.071 in. (0.12 to 1.8 mm), without having to destroy and test the specimen.

Accessories

We provide a large variety of accessories to fulfill any requirement. Customized solutions based on your needs can be made for perfect tests on rough pieces. A series of different anvils is available to test every size of test piece. Variety of accessories to facilitate testing on small or oddly shaped items.

| Force Range | |

| Preload | 3 - 10 kgf (29.42 - 98.1 N) |

| Rockwell | 60 - 100 - 150 kgf (588.4 - 980.7 - 1471 N) |

| Superficial Rockwell | 15 - 30 - 45 kgf (147.1 - 294.2 - 441.3 N) |

| Brinell | 10 - 15.6 - 30 - 31.2 - 62.5 - 187.5 - 250 - 500 - 750 - 1000 - 3000 kgf (98.07 - 153.2 - 294.2 - 306.5 - 612.9 - 1839 - 2450 - 4900 - 7350 - 9807 - 29403 N) |

| Vickers | 3 - 5 - 10 - 15 - 30 - 50 - 100 kgf (29.42 - 49.03 - 98.07 - 147.1 - 294.2 - 490.3 - 980.7 N) |

| LD Series Feasible Tests | |

| LD 3000 Feasible Tests | |

| Brinell / Vickers | Generate Indentation |

| LD 3000 A Feasible Tests | |

| Brinell HBW | 1/10 - 1/30 - 2.5/62.5 - 2.5/187.5 - 5/25 - 5/62.5 - 5/125 - 5/250 - 5/750 - 10/100 - 10/250 - 10/500 - 10/1000 - 10/1500 - 10/3000 |

| Vickers | HV 3 - HV 5 - HV 10 - HV 20 - HV 30 - HV 50 - HV 100 |

| LD 3000 B Feasible Tests | |

| Rockwell | HRA - HRB - HRC - HRD - HRF- HRG - HRL - HRM - HRR |

| Superficial Rockwell | HR15N - HR30N - HR45N - HR15T - HR30T - HR45T - HR15S - HR30S - HR45S - HR15W - HR30W - HR45W - HR15X - HR30X - HR45X - HR15Y - HR30Y - HR45Y |

| Brinell HBWT | 2.5/62.5 - 2.5/187.5 - 5/125 - 5/250 - 5/750 - 10/500 - 10/1000 - 10/3000 |

| Brinell HBW / Vickers | Generates Indentation |

| LD Series Technical Data | |

| Accuracy | Better than 0.5% |

| Principle of Operation | Load Cell and Closed Loop (AFFRI patent) |

| Standards | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / EN-ISO 2039 / ISO 868 / ASTM E10 / ASTM E18 / ASTM E103 / ASTM E384 / JIS |

| Indenter Stroke | 1.2" (30mm) |

| Vertical Stroke | Screw stroke 5.9" (150mm). Removing the elevating screw, the vertical capacity increases to 11.8" (300mm) for large parts. |

| Depth Capacity | 7.5" (190mm) |

| Tolerable Weight | 4400 lbs. (2000 kg). Removing the elevating screw, the tolerable weight can be increased to more than 6614 lbs. (3000 kg). |

| Dwell Time | From 5 to 60 seconds programmable |

| Temperature Range | From 50°F to 95°F (10°C to 35°C) |

| Data Output | LD 3000: RS232 / LD 3000 A - LD 3000 B: USB and LAN |

| Power Supply | 110 - 120 VAC / 50-60 Hz |

| Software | AFFRI - OMAG |

| Fields of Use | For all metals: iron, steel, tempered steel, brass, aluminum and nitriding, cementation, hard facing, plastics |

| Packaging Dimensions | 55.1" x 39.4" x 25.6" (140 x 100 x 65 cm) |

| Packaging Weight | 770 lbs. (350 kg) |

For more information regarding purchasing the AFFRI LD Series Hardness Testers, please contact us here:

Click Here to Request Pricing