| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt SNK KP-8 Automated Rail Wheelset Ultrasonic, Eddy Current, and EMAT Testing System | UT-OKO-SNKKP8 |

|

Request Pricing | ||

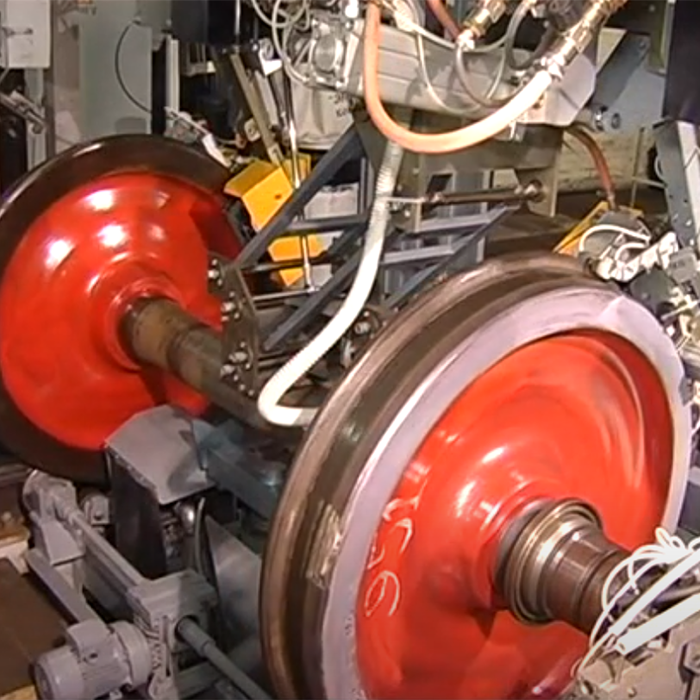

The SNK KP-8 System is intended for detection of both surface and inside flaws in freight railcar wheelsets, as well as measurement of flaw depth and coordinates. Automated inspection is performed on the wheel sets with new machined wheels and a repaired axle. The system is used for automated UT, EMAT and ET of railcar wheelsets at repair plants that assemble and examine the newly formed wheelsets.

Due to simultaneous operation of multiple channels, testing is more productive and reliable by several measures. Detected flaws and all process data are fully recorded by the system during inspections. This helps to avoid mistakes or negligence, and enables detailed analyses to be made of the test results at any time.

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt SNK KP-8 Automated Rail Wheelset Ultrasonic, Eddy Current, and EMAT Testing System | UT-OKO-SNKKP8 |

|

Request Pricing | ||