The Proscan8 takes all the features and benefits of the single channel ProScanXT but now gives you 8 channels. The ProScan8 is a small and low cost device that allows you to collect up to 8 channels of data simultaneously which can increase production and allows you to view data in ways never achieved by other methods such as phased array or TOFD. Smallest and most powerful eight-channel UT Flaw Detector system with 2 axis encoding.

Analysis

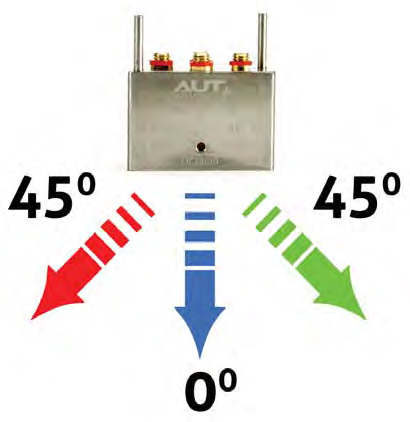

Triplex Transducer

Multi-Channel Data Merging

Raster scan over a weld cap using our triplex transducer and collect both zero degree and outward facing shearwave channels at the same time and image weld flaws easier than ever while monitoring wall thickness and couplant loss which phased array cannot do.

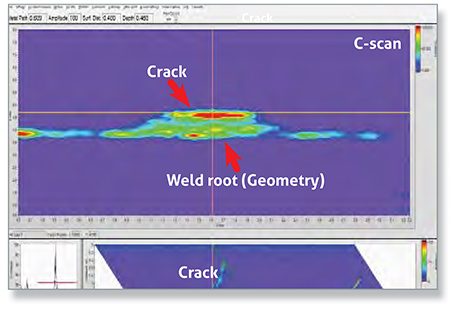

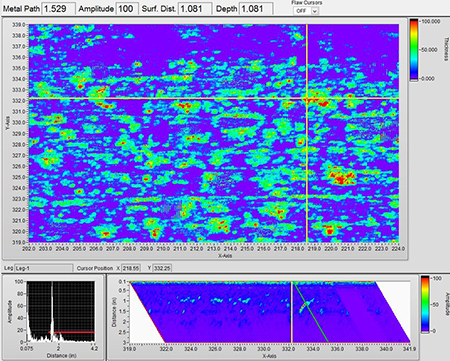

Left: 45 degree shearwave scan of a vessel weld with a 54% thru-wall crack present.

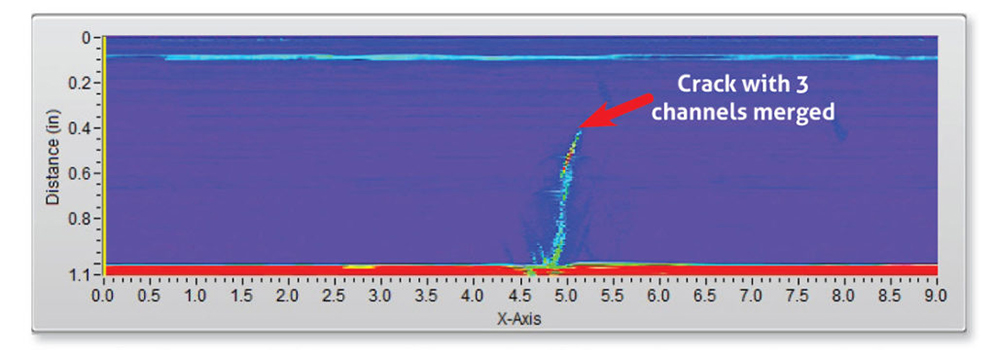

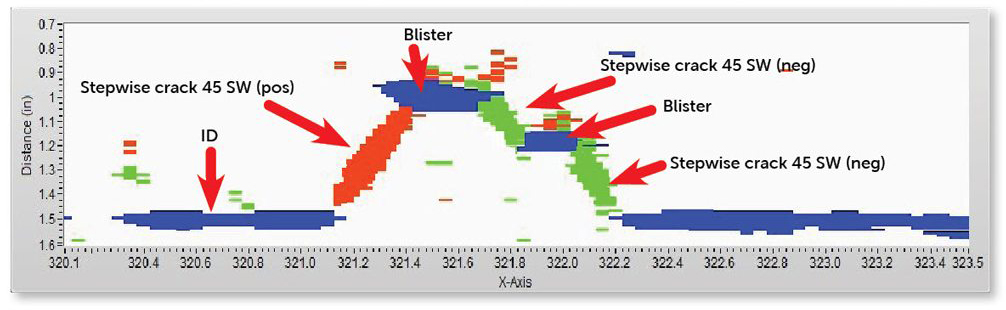

Below: B-scan showing merged 0-degree and 2 opposing 45 degree shearwave channels all on one image, which included the second leg data flipped and super-imposed back onto the 1st leg data for a true cross sectional view of the component.

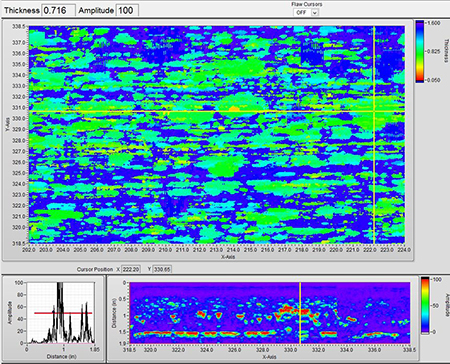

0° Data Showing Hydrogen Blisters

45° Shearwave Data Showing Stepwise Cracking

Multi-Channel Data Merging

Hydrogen induced cracking, or HIC, is a failure mechanism commonly found in refineries around the world. Differentiating between staggered laminations, which have less potential to cause failure, and hydrogen blister with step wise cracking, which comes at extreme risk of failure, is not something easily done with even advanced UT techniques such as phased array or TOFD. It is very important to view both 0-degree data with shearwave data at the same time so you can see the blister from the 0-degree data and then the crack signals from the shearwave channels as you will not see blisters with shearwaves. The ProScan software has the ability to merge these channels but also allows you to specify a color for each channel so you can clearly see the blister signal and then the cracks coming off of them.

Below: Merged B-scan image of three channels at different colors depicting the blister and stepwise cracks coming off of them; in this case:

Blue - 0°, Red - 45°-Skew-90 (pos), Green - 45°-Skew-270 (neg)

| General | |

| Dimensions | 3.75” x 2.75” x 1.50” |

| Weight | 10 oz |

| Connections | UT, 2 Lemo 00: 1 pulser / receiver & 1 Receiver |

| PC/Power | 1 USB 2.0 (up to 480 Mbps) |

| Operating System | All Windows OS compatible |

| Pulser | |

| Voltage | 10-250 V |

| Pulse Width | 10 ns – 0.4 μs |

| Receiver | |

| Gain | 0 – 90 dB, in steps of 0.1 dB |

| Bandwidth | 0.50 – 25 MHz |

| Acquisition | |

| Sampling Rate | 25/50/100 MHz |

| Transducer Mode | Single (pulse echo)/Dual (pitch-catch-through transmission) |

| PRF | 6 Hz – 2 KHz |

| Processing | |

| Rectifier | Full, +half, -half, RF, & Envelope |

| Filters | 2.5/5/10 MHz; Broadband |

| Resolution | 12 bit live A-scan, 8 bit for stored data |

| Screen Linearity | ±5% |

| Linearity | ±1 dB on total gain dynamic |

| Encoder | 5 v TTL (15 pin Sub-D), 100mA |

To purchase the ProScan8, please contact us here: