The Affri Wiki 30 is a fully motorized portable hardness tester for Micro/Macro Vickers and Knoop testing methods with indentation auto-reading. It was designed specifically for the Oil & Gas market for testing on bulky tubes or valves in compliance with ASTM E384, ISO 6507 and ISO 4545 standards. The Wiki 30 features an automatic measurement system with autofocus and auto indentation readings, a swiveling turret with 0.2" (5mm) horizontal stroke, and can operate up to 360° of positioning, even upside down.

How it Works:

Load forces are applied through a load cell which assures high accuracy in every condition long term. Micro/Macro Vickers, Knoop and case depth tests, in the laboratory or on site. It is not affected by any external source of vibration, and does not need to be leveled.

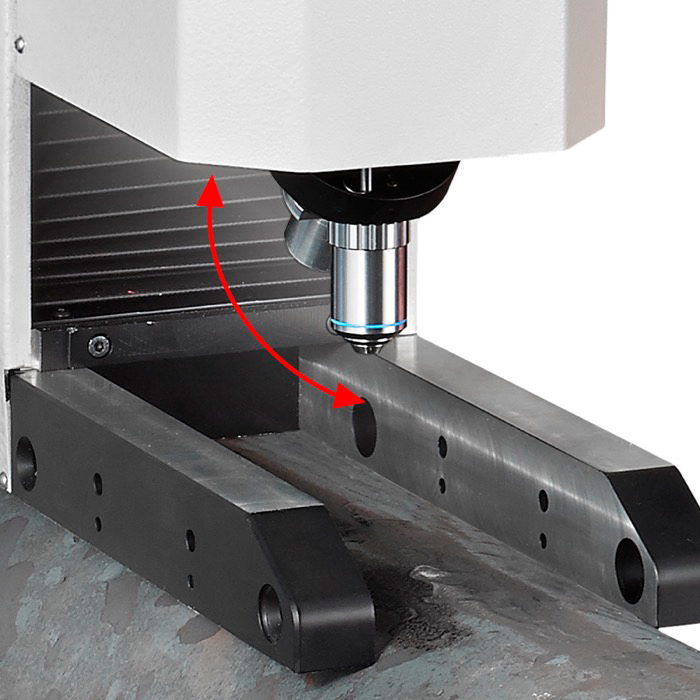

Motorized Measuring Head and Turret (Indenter/Objective)

Just press one button and the head moves down, applies the force, makes the indentation, reads the indent and moves back upward. Fully motorized with 3.5" (90mm) vertical stroke. One slot for an indenter and one slot for an objective. Auto-rotating and auto-tool-switching for a complete automatic measurement cycle.

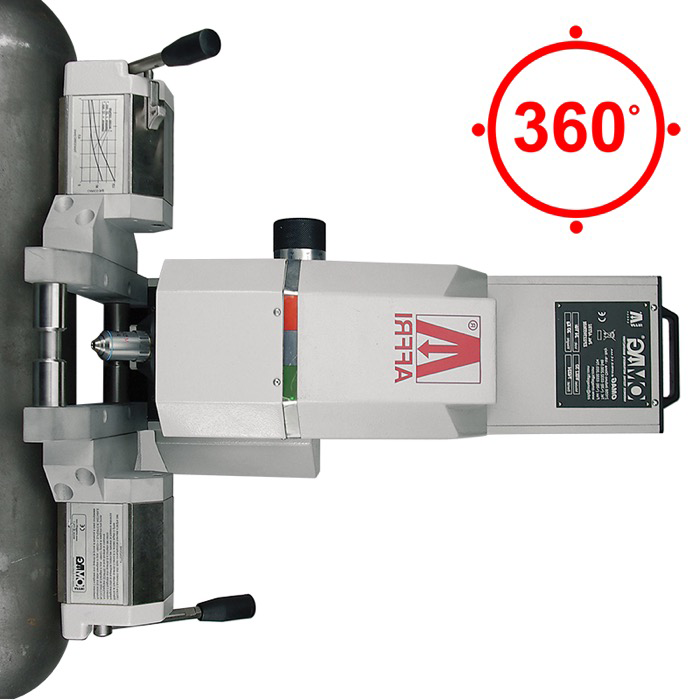

360° Positioning

It is completely uninfluenced by direction so that it can operate up to 360° degrees of positioning, even upside down. Safe clamping on any surface, from round to flat, with self-alignment of the indenter with the measurement axis.

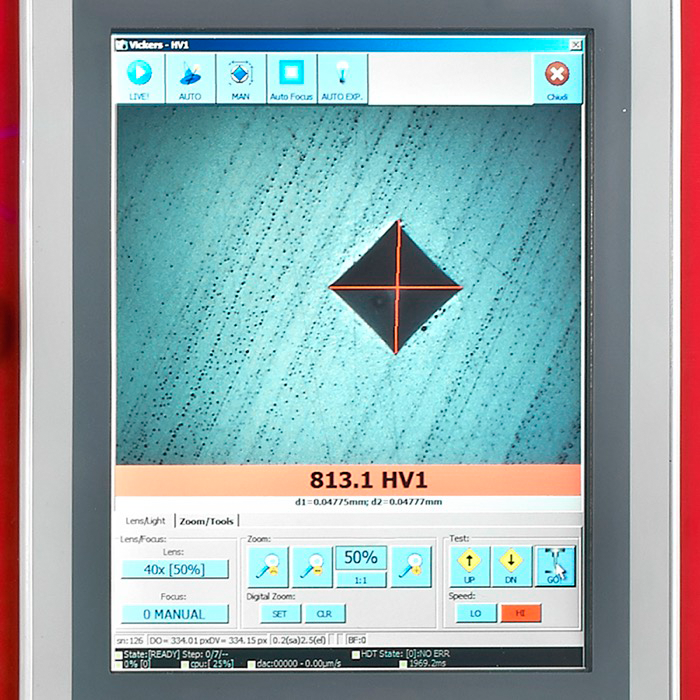

Touchscreen and Software

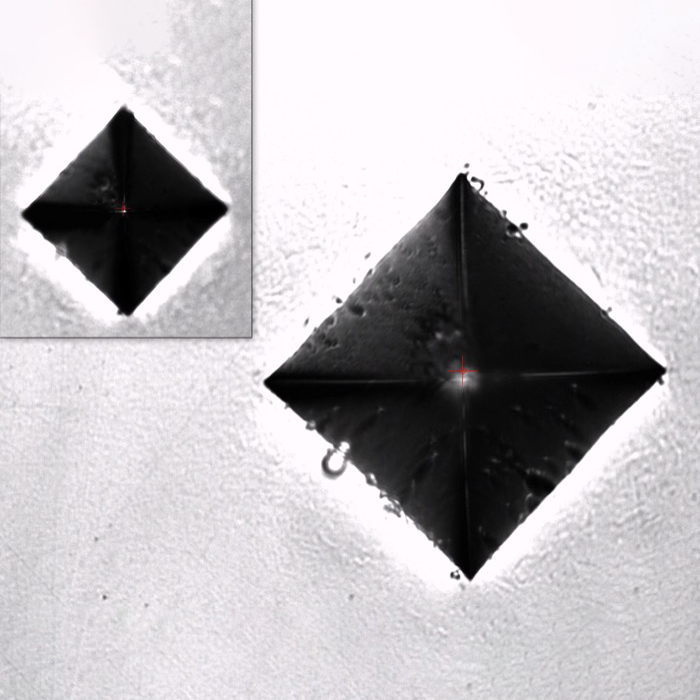

Powerful software for test cycle management and automatic indent reading. Wide settings parameters for measurement setup, image adjustments, statistics and data storage.

Auto Focus

The Auto Focus performs an automatic focus adjustment for the selected optic with precise positioning at any magnification. This system reduces reading time thus assuring high reading accuracy.

| Affri Wiki 30 Specifications | |

| Standards | DIN-EN-ISO 6506 / DIN-EN-ISO 6507 / DIN-EN-ISO 4545 / ASTM-E92 / ASTM 384 / JIS Z231 |

| Horizontal Head Stroke | 0.2" (5mm) |

| Vertical Head Stroke | 0" - 3.5" (0/90mm) motorized |

| Objectives | 100x, 200x, 400x |

| Indenters |

Vickers (Knoop and Brinell on request) |

| Test Loads |

Vickers (Knoop on request): 0.9807 - 1.961 - 2.942 - 4.903 - 9.807 - 19.61 - 29.42 - 49.03 - 61,29 - 98.07 - 147.1 - 152.98 - 196.14 - 245.17 - 294.21 N (0.1 - 0.2 - 0.3 - 0.5 - 1 - 2 - 3 - 5 - 6.25 - 10 - 15 - 15.6 - 20 - 25 - 30 kgf) |

| Feasible Tests |

Vickers: HV0.1 - HV0.2 - HV0.3 - HV0.5 - HV1 - HV2 - HV3 - HV5 - HV10 - HV20 - HV30 Knoop: (On request) HK0.1 - HK0.2 - HK0.3 - HK0.5 - HK1 Brinell: (On request) |

| Load Accuracy | Better than 0.05% |