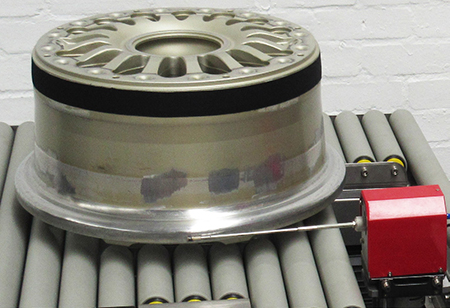

The VeeScan has a proven mechanical design and established record of breakdown-free operation for 365 days or more. Appealing to many companies in the Aerospace industry, the VeeScan is ideal in all wheel-testing environments. The VeeScan can be configured with a wide choice of probes and allows any wheel testing facility the flexibility to select the system most compatible with their workload. Teamed with a full choice of operation modes, the VeeScan maximizes the probability of detection and is offered with the ETher NDE guarantee of complete client satisfaction and excellent technical support. The VeeScan H is designed to lift the wheel and fix it with an automatic adaptor that uses the wheel inertia to center it. VeeScan H offers an integrated roller tray for easy maneuverability and integration into a conveyor system and can test wheels up to 900mm diameter. The H is designed with an adjustable-height Control Panel for operator comfort and can be positioned at a convenient distance from the main machine. Open on three sides, it offers easy wheel loading as standard.

Designed by the original engineers of the Hocking Wheelscan

The Control Panel is used to program the inspection and control the moving elements of the VeeScan. Via USB it interacts with the AeroCheck+ display inspection signals. From the Control Panel the user can export a PDF report of the inspection, including all relevant industry inspection and eddy current testing parameters. The VeeScan Control Panel can be configured as a standalone unit or on a pivot arm attached to the machine. Either option ensures the safety of the inspection team, offering ease-of-use with the ability to re-position when required. The stand alone unit is designed with an adjustable-height Control Panel for operator comfort and can be positioned at a convenient distance from the main machine.

The VeeScan works in conjunction with the AeroCheck+, which sits behind a protective tough polycarbonate window and provides the unit with the eddy current technology for the inspection and is used to program the wheel-scanning probe. With the ability to pre-program the probe the operator can guarantee the correct set up is being used for the current inspection job. The simplicity of having the AeroCheck+ in its own housing on the front of the machine also means that it is readily available to be used as a stand-alone unit for manual inspection if needed. The unit transmits the eddy current signals to the VeeScan Control Panel PC offering stable eddy current performance, high resolution and the flexibility that the AeroCheck+ is known for.

The VeeScan is designed to lift the wheel and fix it with an automatic adaptor that uses the wheel inertia to center it. It offers an integrated roller tray for easy maneuverability and integration into a conveyor system. The VeeScan also features an automatic hub size adaptor and can test wheels up to 35” (900mm) diameter. A circular absolute probe is positioned perpendicular to the surface to ensure uniform sensitivity regardless of wheel surface profile as the probe progresses through the wheel bead seat area. Recommended frequency is 200kHz.

| Instrument | ETher NDE AeroCheck+ |

| NSN (National Stock Number) | 4920016445049 |

| Probe | Differentially connected absolute (integral balance load) with circular head. Recommended Frequency 200kHz, option 100kHz, 500kHz and 1.5 MHz. Recommended diameter 0.25” (6mm). 0.35” (9mm) also available and narrow shaft for large wheels |

| Max Wheel Diameter | 0-35" (0-900mm) |

| Max Wheel Height | 16” (400mm) |

| Max Load | 330 lbs. (150kg) |

| Typical Inspection Helix | 0.06” (1.5mm) |

| Rotation Speed | 15-120 rpm |

| Probe Position | Adaptive contour following using dual axis pressure sensors with fully bi-directional control |

| Alarms | Acoustic and visual |

| Frame | Extruded Aluminum |

| Wheel Position | The wheel is lifted clear of the roller tray using a 250mm (10”) stroke electric actuator and then held under its own weight by an adaptive automatic grip mechanism |

| Automatic Calibration | Yes, by means of dynamic standard option |

| Automatic Stop on Defect | Yes |

| Turntable | Roller Tray Rubber coated steel rolls |

| Control Station | External free standing, height adjustable pedestal or machine mounted pivot arm. With machine and eddy current control. 7” screen, keyboard and tracker ball. |

| Machine Weight | 600 lbs. (275 kg) |

| Dimensions (WxDxH) |

34” x 44” x 37” (850 mm x 1120 mm x typical 945 mm) Minimum height 36” (904 mm), Maximum height 38” (975 mm). Height adjustable via feet. |

| Power Supply | 110-240V AC 50/60Hz |

| Item | Part Number |

| Veescan - Model H - Base Unit Pedestal Control Panel | IVEE001-H |

| AeroCheck+, Dual Frequency, (10Hz-12.8MHz) | IAER002 |

| WheelScan, Head Dia 6mm, 2MHz, Fine | PA06-002FB |

| Lead, Lemo 12-Way (90 deg) - Lemo 4-Way, 2.5m (Bridge) | ALL12R-L04-025B-V |

| PC-Desktop (Intell Cori i3-8100 Quad Core Processor, 4GB DDR | A210 |

| USB Trackerball | A227 |

| Mini USB Keyboard Max 18 * 30cm | A228 |

| HP Color LaserJet Pro M254dw A4 | A229 |

| 3m USB Cable, USBA-USBBl | A253 |

| USB Type A Plug to Mini USB Type B Plug cable minimum | A254 |

| Ethernet cable minimum length of 6 feet long | A271 |

| Weld/Aero/EtherCheck, Power Adapter + Input Plugs | AWEL002 |

| Power Lead 1.5m, R/Angle Power Plug | AVEE002 |

| TAPE - Kapton Insulating - 12mm Wide x 33m (Reel) | AW009 |

To purchase the VeeScan H, please contact us here: