| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

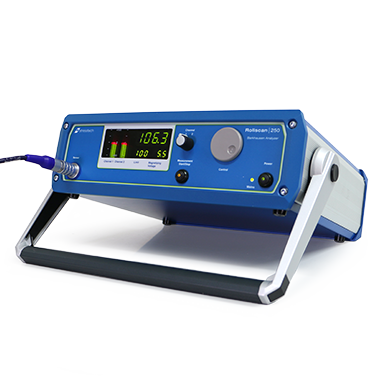

| Rollscan 250 | SM-STECH-ROLLSCAN250 |

|

Request Pricing | ||

| Rollscan 350 | SM-STECH-ROLLSCAN350 |

|

Request Pricing | ||

| Rollscan 320 | SM-STECH-ROLLSCAN320 |

|

Request Pricing | ||

The StressTech RollScan Barkhausen noise signal analyzer instruments are designed for surface quality control and testing of near-surface defects in a wide variety of ferritic steel and other ferromagnetic materials and easily detects defects related to changes of stresses or microstructure. Inspection with Rollscan is fast and can easily match production rates, resulting in significant quality improvements and savings on material and labor expenses. A wide variety of sensors make inspection systems using Rollscan flexible: Piston pins, gears, bearing rings and rollers, camshafts and crankshafts, and landing gears are just some of the parts that can be successfully tested.

The Rollscan 250 is a full-featured, self-contained unit which is portable for on-site measurements while also providing advanced capabilities for in-line and laboratory use. Designed for surface quality control and testing of near-surface defects such as grinding burns, heat treatment defects, as well as changes in stress and microstructure in a wide variety of ferritic steel and other ferromagnetic materials.

Features

Rollscan 350 is a full-featured, self-contained unit which is portable for on-site measurements while also providing advanced capabilities for in-line and laboratory use. Designed for surface quality control and testing of near-surface defects such as grinding burns and heat treatment defects, as well as changes in stress and microstructure in a wide variety of ferritic steel and other ferromagnetic materials.

Features

Rollscan 320 is a compact unit with low power consumption. It is designed for deployment in automated systems and production environments. Designed for automated surface quality control and testing of near-surface defects such as grinding burns, heat treatment defects, as well as changes in stress and microstructure in a wide variety of ferritic steel and other ferromagnetic materials.

Features

| Feature | Rollscan 250 | Rollscan 350 | Rollscan 320 |

| Measurement Channels | 2 | 1 | 2 (with 8 parallel analyzers up to 16 channels) |

| Magnetizing Voltage Range | 0-16 Volts | 0-16 Volts | 0-16 Volts |

| Magnetizing Waveform Sine/Triangle | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ |

| Magnetizing Frequency Range Sine/Triangle | 1-1000 Hz/1-150 Hz | 1-1000 Hz/1-150 Hz | 1-1000 Hz/1-150 Hz |

| Analyzing Filter Range | 70-200 kHz | 10-70 kHz, 70-200 kHz, 200-450 kHz | 70-200 kHz |

| Magnetizing & Frequency Sweep | X | Automatic/Visible | X |

| Communications | Ethernet/USB/RS232 | Ethernet/USB | Ethernet |

| Measurement Parameter Control | Manual/Remote | Manual/Remote | Remote |

| Oscilloscope Display/Software | X / X | ✓ / ✓ | X / ✓ |

| Battery Option | ✓ | ✓ | X |

| MicroScan Option | X | ✓ | X |

Barkhausen noise analysis is a non-destructive method involving the measurement of a noise like signal induced in a ferromagnetic material by an applied magnetic field. There are two main material characteristics that will directly affect the intensity of the Barkhausen noise signal: hardness and stress. The noise intensity continuously decreases in microstructures characterized by increasing hardness, and compressive stresses will decrease the intensity of Barkhausen noise while tensile stresses increase the intensity.

Measurement Process

Performing Barkhausen noise measurements is a simple process:

Click below for more information on Barkhausen Noise Analysis:

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Rollscan 250 | SM-STECH-ROLLSCAN250 |

|

Request Pricing | ||

| Rollscan 350 | SM-STECH-ROLLSCAN350 |

|

Request Pricing | ||

| Rollscan 320 | SM-STECH-ROLLSCAN320 |

|

Request Pricing | ||