Eddycon C can be used with a wide variety of eddy current probes, including most competitors' probes. See below for a quick guide to the different kinds available:

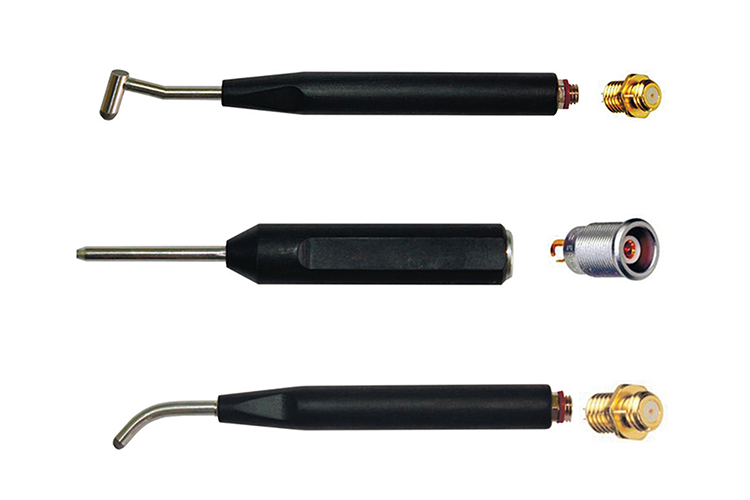

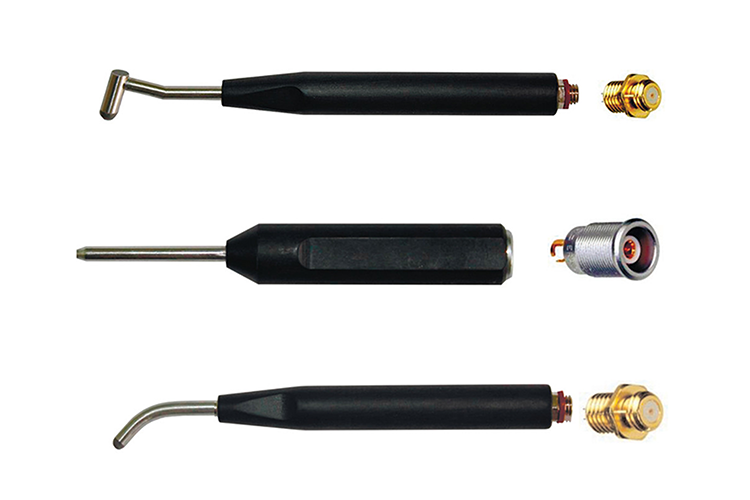

Surface Probes:

Surface Probes are handheld and are used by making contact with the test surface. They use relatively high operating frequencies (over 1 MHz) and are good for detecting surface defects that are oriented perpendicular to the test surface.

Sub-Surface Probes:

In order to detect flaws such as corrosion in the layers of multilayer aircraft structures, Subsurface Probes are required. Sub-Surface Probes allow effective eddy current testing even without removing fasteners or disassembling structures.

Manual Rotating Probes:

Manual Rotating Probes (aka Bolt Hole Probes) are used for detecting surface cracks on the inside of fastener holes. They are available in virtually every diameter and cover a range of diameters (0.5 or 1 mm). They are available as absolute and differential models with a frequency range of 200 kHz to 3 MHz.

Dynamic Rotating Probes:

Dynamic Rotating Probes (aka Dynamic Bolt Hole Probes) are used for testing bolt holes and countersinks. They are specifically designed to be used with the OKOndt SVR Rotating Probe Drive and Eddycon Flaw Detectors. They can be supplied as shielded or unshielded models with operating frequencies from 200 kHz to 3MHz.

Weld Probes:

Weld Probes are specifically designed for testing painted steel structures like offshore drilling rigs, bridges, etc for fatigue cracks that typically occur at the toe of a weld and in the HAZ, which is difficult to inspect due to changes in magnetic properties like lift-off. OKOndt’s Weld Probes are specially designed differential probes that optimize the signal from a crack while minimizing the effects of lift-off and permeability (due to variable coating thickness and magnetic properties).

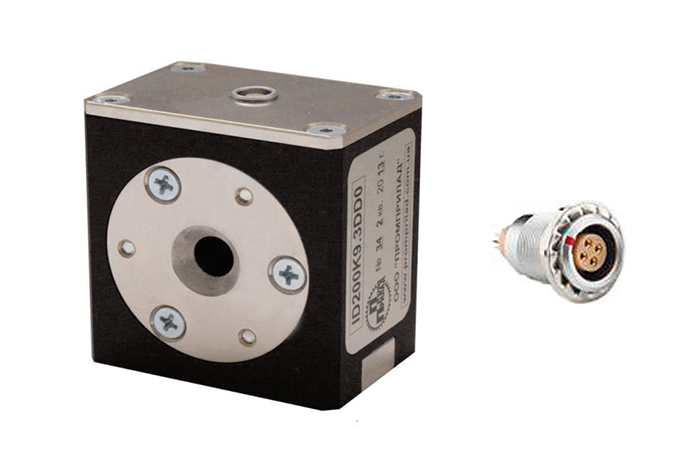

Encircling Probes:

Encircling Probes are designed for testing cylindrical objects made of non-magnetic materials, like steel bars. As the name implies, they generally “encircle” the material to be tested and inspect from the outer diameter. OKOndt’s Encircling probes can be used in an absolute mode or differential mode when paired with a 2nd coil. They are used for sorting (alloy or hardness), as well as in flaw detection applications such as weld defects, cracks, etc. in rods and tubing.