| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt SNK KB-13 Automated Wheel & Rim UT System | UT-OKO-SNKKB13 |

|

Request Pricing | ||

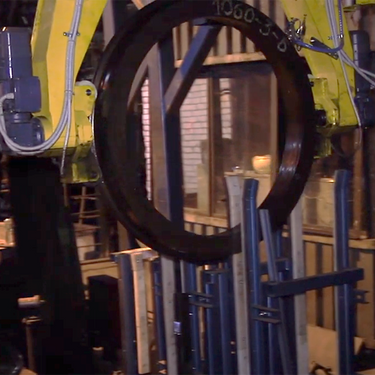

The SNK KB-13 System is intended to be installed in the line control assembly with of wheel and rim products. Assures wheel and rim testing is in compliance with AAR M 107/208 and EN 13262, UIC 810-1, ISO 5948, with the subsequent return of the tested products to the finished products acceptance stand. The SNK KB-13 System performs ultrasonic testing of the car wheel/wheel tread in axial and radial directions and testing of the wheel hub in two opposite directions by the ultrasonic method. Subsequent documentation of test results are transferred to the server along with imaging of the test process, the test results verification for compliance with the standard, and test results data.

Finished and machined railway wheels and rims with the following parameters can be used in the KB-13 System:

Tests the tread of a car wheel in axial and radial directions

Minimal defect diameter – 1 mm, Minimal depth of the defect – 5 mm

Tests wheel hubs in the axial direction

Minimal defect diameter – 3 mm, Minimal depth of the defect – 5 mm

Test configurations that allow to limiting defect quantity and the distance between the defects in compliance with the standards

Evaluation of the defects parameters (defect depth, approximate coordinate, amplitude, equivalent defect size, equivalent area in millimeters)

Defect parameters display in the “Defects Table/Defectogram”, in the A-Scan, B-Scan, and C-Scan, saving the data to the System memory, with ability to print them out

Light and sound Defect Alarm

Various test configurations can be saved with different probe sets, coordinates, travel speeds

Good product and defect marking with paint in order to confirm the defect further in manual mode

Test results (protocols) output in electronic version in .xls or .pdf formats with ability to print them out on paper

Operated by dedicated software which enables automatic management of the System mechanical units, as well as the test results reading, processing, and recording

System design ensures the safety of maintenance personnel with automatic blocking, alarm, and emergency shutdown

| Generator Sounding Pulse Amplitude | Not less than 180 V at the pulse duration (60 ± 20) ns and the duration of the leading edge is not more than 20 ns |

| Probe Operating Frequency | 4-5 MHz |

| Number of Ultrasonic Channels | 6 |

| Maximum PRF | 2000 Hz |

| Channel Sensitivity (Signal to Noise Ratio) | 16 dB |

| Involute Measurement Step | Adjustable within 1 to 8 mm |

| Absolute Error of the Defect Depth | Not more than ±3 mm |

| Absolute Error of the Defects Relative Position Along the Scanning Path | Not more ± 15 mm |

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt SNK KB-13 Automated Wheel & Rim UT System | UT-OKO-SNKKB13 |

|

Request Pricing | ||