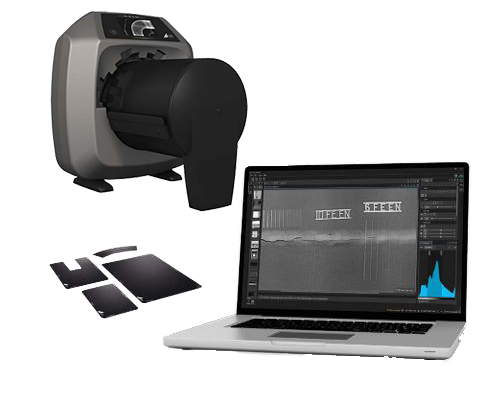

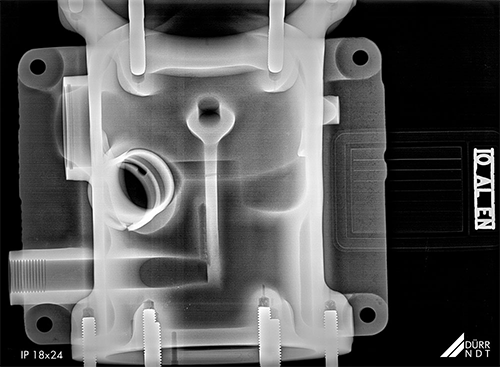

Whether for a portable application in the field or as part of the production process, with the HD-CR 35 NDT you have peace of mind, now and in the future. This is in part due to its unique TreFoc Technology, allowing the widest range of applications and the highest resolution of all CR scanners. The CR 35 NDT without TreFoc Technology is ideal for erosion and corrosion inspections and any general NDT inspections you might have with high resolution. Both the HD-CR 35 NDT & CR 35 NDT fully comply to the relevant EN, ASTM and DICONDE standards and both come with a 5 year guarantee.

With TreFoc the laser beam is adjusted perfectly to give optimal image results and the highest signal-to-noise ratio in any application. Inside the laser tube, an iris diaphragm adjusts the laser beam diameter. Since the perfect laser beam diameter can be selected for each object and image type, optimum results for any particular application can be easily achieved. Regardless of the application – high-resolution image or low-exposure corrosion measurement – the unique TreFoc Technology gives perfect image results with the best SNR every time. So every Imaging Plate type can be read with a laser beam focused specifically for that plate, thus always achieving the best image with the lowest noise.

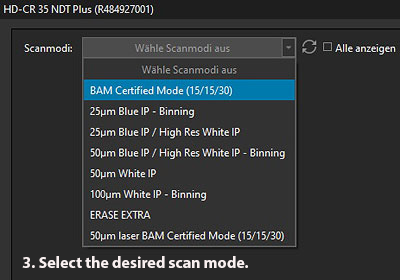

After the object has been selected, the scanner sets all scan parameters perfectly so that an optimal image result can always be expected

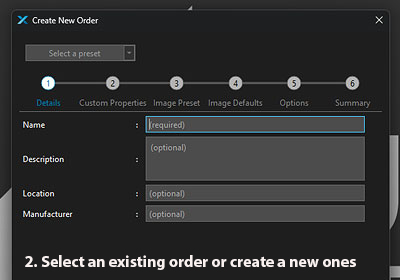

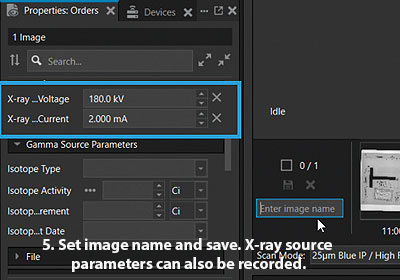

If required, various predefined fields may be filled with additional information like kV, mA and exposure time. In order to distinguish different sites or tasks, those may be added also. If no additional information is required, this step may be skipped.

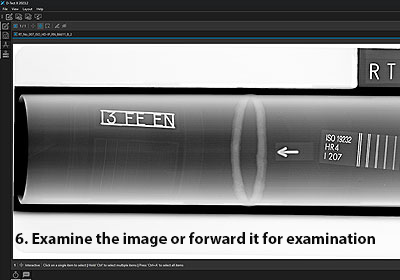

After the scan has taken place, the quality of the image can be checked on the built-in display and released for storing.

| Description | HD-CR 35 NDT | CR 35 NDT |

| Laser Spot Size | 12.5 – 25 – 50 µm, TreFoc Technology | 50 µm |

| SRb (Basic Spatial Resolution) | 30 µm, BAM certified* according to ISO 16371-1, ASTM E 2445, ASTM E 2446 | 80 µm |

| Grayscale Resolution | 16 bit (65.536 gray levels) | |

| Min./Max. imaging plate size (W x L) | 0.8 to 14" x 1.2 to 79" (2 to 35 cm x 3 to 200 cm) | |

| Dimensions (H x W x D) | 15.8 x 14.6 x 18.5" (40 x 37 x 47 cm) | |

| Weight | 38.6 lbs. (17.5 kg) | |

| Power supply | 100 – 240 VAC / 50 – 60 Hz < 140 W | |

| Operating Temperature | 50 to 95°F (10 to 35°C) | |

| Noise level | < 39 dB(A) | |

| Laser class | I (EN 60825-1: 1994-03 + A1: 2002-07 + A2: 2001-03) + CFR 1040.10 | |

| Interfaces | Ethernet, WLAN | |

| Touchscreen | 4.3" TFT, 800 x 480 px | |

| Internal storage | SDHC, max. 32 GB | |

| Software | DÜRR NDT D-Tect (DICONDE compliant to ASTM 2339) | |

| Imaging Plates | High sensitivity, regular definition, high resolution, ultra-high resolution | |

| Standard Formats | 6 x 24 cm, 6 x 48 cm, 10 x 24 cm, 10 x 48 cm, 18 x 24 cm, 24 x 30 cm, 30 x 40 cm, 35 x 43 cm, 4.5 x 10", 4.5 x 17", 5 x 7", 8 x 10", further formats and individual shapes available by request. | |

For more information on how to purchase these items, click on the links below.