| ETher NDE WeldCheck Specifications |

| Probe |

WeldCheck 2 |

WeldCheck+ |

| Connectors |

12 Way Lemo 2b (Absolute, Bridge and Reflection) and Connection Lemo 00 (for single element absolute probes).

|

Simulataneous probe operation possile using Lemo 12 way and Lemo 00

|

| Frequency |

Single Freq. = 10Hz - 20MHz with range variable resolution |

Dual Freq. = 10Hz - 12.8MHz |

| Gain |

| Overall |

-18 to +100 dB, 0.1, 1 and 6dB steps (100dB maximum) |

| Input |

0dB or 12dB |

| Drive |

0dB, 6dB and 10dB (0dB reference 1mW into 50 ohm) |

| Max X/Y Ratio |

+/-100.0 dB |

| Phase |

| Range |

0.0-359.9°, 0.1° steps |

| Auto Phase |

Allows phase angle to be automatically set to a pre set angle |

| Filters |

| Normal High Pass |

DC to 2kHz or Low Pass Filter, which ever is the lower in 1 Hz steps. Plus variable adaptive balance drift compensation 0.01 - 0.5 Hz (6 steps) |

| Normal Low Pass |

1Hz to 2kHz or a quarter of the lowest test frequency, which ever is lower in 1 Hz steps |

| Balance |

| Manual |

14 internal balance loads; 2.2μH, 5.0μH, 6.0μH, 6.5μH, 7.0μH, 7.5μH, 8.2μH, 12μH, 15μH, 18μH, 22μH, 30μH, 47μH, 82μH |

| Automatic |

Optimized balance load selection |

| Alarms |

| Box |

Fully configurable, Freeze, Tone or visual |

| Sector |

Fully configurable, Freeze, Tone or visual |

| Output |

Open collector transtor (50v dc at 10mA max) available on 12 way lemo |

| Display |

| Type |

5.7” (145mm), 18 bit Color, daylight readable |

| Viewable Area |

115.2mm (Horizontal) x 86.4mm (Vertical) |

| Resolution |

640 x 480 pixels |

| Flip |

Manual or automatic screen orrientation change to enable left or right handed use |

| Color Schemes |

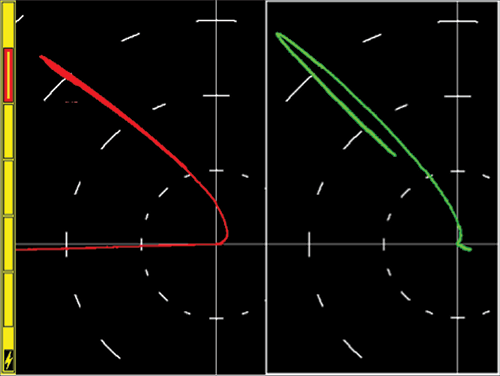

User configurable Dark, Bright and Black & White |

| Configurable Screen |

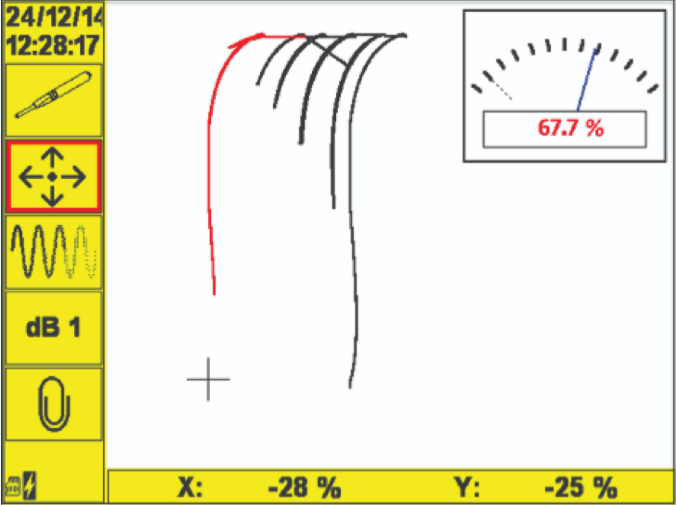

Full Screen, Single, Dual Spot or Dual Pane with variable size and location and function e.g. XY, Timebase, Waterfall and Meter |

| Display Modes |

Spot, Time base (0.1-20 seconds x 1-200 sweeps and up to 55 seconds), Waterfall and Meter with peak hold and % readout |

| Graticules |

None, Grid (4 sizes 5, 10, 15 and 20% FSH), Polar (4 sizes 5, 10, 15 and 20% FSH) |

| Offset |

Spot Position: Y =-50 to +50, X =-65 to +65% |

| Digital Spot |

Display in X,Y or R,θ |

| Position Readout Summary |

Display of all settings in Legacy Format |

| Removable Data Storage |

| Setup Storage |

micro SD up to 32GB, holding over 10,000 settings |

| Stored Screen |

micro SD up to 32GB, holding over 10,000 screen shots |

| Shots |

Comprehensive Record Replay and Storage |

| Record Replay |

Real-time recording of trace data and Replay on instruments and desktop PC up to 164 seconds |

| Outputs |

| PC Connectivity |

USB (Full PC remote control plus Real Time data) |

| Digital Volt Free Alarm |

On Lemo 12 way Open collector transistor (36v dc at 10mA max). |

| VGA |

Full 15 way VGA output |

| General |

| Languages |

English, French, Spanish, Russian, Japanese, Chinese, Turkish |

| Verification Level |

The system includes on delivery a 2 year validity Verification Level 2 detailed functional check and calibration as per ISO 15548-1:2013 |

| Power on Self Test |

The system performs a self test on start up of external ram, sd ram, accelerometer, Micro SD card, LCD screen buffer |

| Power |

| External |

100-240 v 50-60Hz 30 Watts |

| Battery |

Internal 7.2V nominal @ 3100mAh = 22.32 watt.hr |

| Running Time |

Up to 8 hours with a 2MHz Pencil Probe 30% Back Light and up to 6 hours with a Rotary Drive at 3000rpm 50% duty cycle |

| Charging Time |

2.5 hrs. charge time, Simultaneous charge and operation |

| Physical |

| Weight |

1.2 kg, 2.7 lbs |

| Size (WxHxD) |

237.5mm x 144mm x 52mm / 9.4” x 5.7” x 2.1” |

| Material |

Aluminum alloy Mg Si 0.5 powder-coated |

| Operating Temp |

-20 to +60 °C |

| Storage Temp |

Storage for up to 12 months -20 to +35 °C Nominal +20 °C |

| IP Rating |

54 |