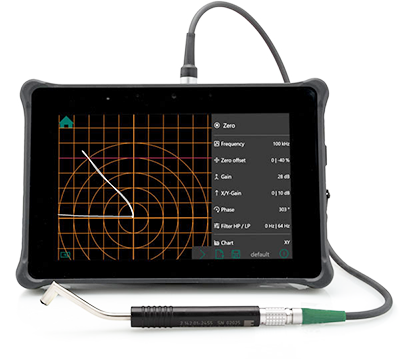

FOERSTER’s versatile new TCM 2.142 serves as a unifying platform for established eddy current testing products. Deep-penetrating low frequency (LF) testing with DEFECTOSCOP for measuring residual wall thickness and high frequency (HF) testing with DEFECTOMETER for detection of the smallest cracks, as well as, conductivity measurement of non-ferromagnetic materials with the SigmaTest. ECA (Eddy Current Array) eddy current testing via sensor arrays with up to 512 channels is available too. The intuitive touch interface allows the user to select the individual tasks via corresponding apps. Automatic probe recognition helps you set the optimal test and measurement parameters to achieve the best possible results.

The DEFECTOSCOP module uses all typical parameters of a universal eddy current tester and displays the measurement data in the impedance plane. A user working in expert mode can easily customize the list of available parameters and store them in the test program. Additionally, favorites can be defined so the module starts up quickly the next time. Switching from expert mode back into operator mode locks the parameter list and system settings for editing, saving time and effort.

Optionally, multiple frequencies can be added to the test program so that parallel testing can be carried out at different eddy current penetration depths. The color representation of the frequencies can be adjusted as desired. Recordings of spinning components or hand-held rotating probes can be displayed directly in a high-resolution C-scan, allowing the test area to be easily evaluated and fully documented, or the raw data of the eddy current signal can be recorded and exported for later evaluation on the workstation computer.

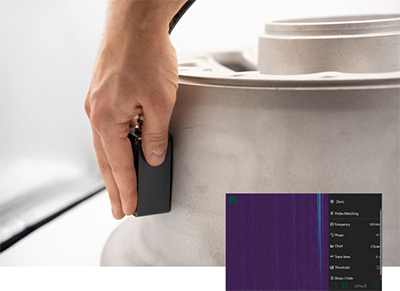

The SIGMATEST is useful for testing material compositions and sorting metals, alloys and scrap. Further applications include the detection of heat damage during aircraft maintenance, as well as process control in production in the metals industry. The SIGMATEST module is used with special conductivity probes that are calibrated to traceable conductivity standards (PTB/NIST or NPL) at 20°C in the FOERSTER calibration laboratory. The calibration data are stored on the sensor and retrieved by the TCM. This enables exact conductivity measurements. A single measurement is triggered by touch. If a scan of the surface is required, measured values can be output continuously and displayed in a time diagram.

When the areas to be scanned are large, conventional eddy current inspection can be very time-consuming. Plus, there’s the risk that manual probe guidance will leave some areas uninspected. The ECA module makes it possible to run both large-area and shape-matched array probes. This permits large areas to be scanned both quickly and comprehensively. Array probes consist of several individual sensors arranged in a row inside a housing, for example. Connecting multiple sensors together in this way allows a larger area to be scanned at the resolution of each individual sensor.

A wide variety of probe elements with corresponding properties are available for crack detection. Probes can be built with other options, such as integrated guidance or wear protection made of e.g. titanium. Each probe element can also be constructed as an array probe with up to 512 integrated elements.

For crack testing, the sensitivity of the testing system is adjusted using primarily flat crack standards made of the material under test. Since test sensitivity depends on the quality of the standard, the standards must comply with the highest dimensional tolerances. Alternatively, setting up test systems with rotating probes for crack testing requires standards, again, made of the material to be tested with representative holes.

Appropriate conductivity standards are used to check and set up conductivity measurement with the SIGMATEST module. The better the quality of this reference standard, the better the final measurement result. FOERSTER offers conductivity standards traceable to an AC measurement of the NPL.

| TCM - General Specifications | |

| Display: |

|

| Protection: | IP 66, 1.5m drop height |

| Dimensions: | 234 x 157 x 51 mm |

| Weight: | 1.3 kg |

| Temperature: | -20° to 50°C operating range |

| Power: | Battery time: 6 hrs. |

| Power Supply, mains: | 100 - 240 VAC, 50/60 Hz, 65W |

| Power Supply, USB-C: | 5 V, 2 A (connection to a standard power bank) |

| Battery: | 7.6 V, 7,200 mAh |

| Camera: | Back camera with 8.0 MP, front camera with 2.0 MP |

| Storage: | 128 GB SSD |

| Connections Ports: | 19-pin LEMO, Thunderbolt 4, USB 3.2 Gen2 (type C), microSD reader |

| Connectivity: | Wi-Fi 6E, Bluetooth V5.2 |

| Audio: | Audio in/out (combo jack) |

| Documentation: | Save/export raw data, screenshots, reports |

| Operating System: | Windows 10 LTSC (Long Term Servicing Channel) |

| Embedded Help: | Find information in every setup and dialog for fast and save usage |

| Languages: | English, German, Spanish, Japanese, Chinese, Czech, Italian, French, further languages on request |

| TCM Test Channel | |

| Frequency Range: | 4 Hz – 20 MHz adjustable in 1 Hz steps |

| Multi-Frequency: |

|

| Filter: | Low-pass filter and high-pass filter 1 Hz – 20,000 Hz |

| Gain: | -20 dB to +120 dB in 0.1 dB steps |

| Phase: | 0° – 360° in 0,1° steps |

| X and Y Gain: | 0 – 60 dB in 0,1 dB steps |

| X/Y Offset: | -50/50 in 5 % steps |

| Probe Recognition: | Automatically adjusts pre-amplifier, max output current |

| Pre-Amplifier: | -18, -12, -6, 0, 6, 12, 18, 24, 30, 36 dB |

| Max Output Current: | 400 mA (peak), 10 V peak-peak |

| Data Resolution: | 32 bit |

| Sample Rate: | Up to 40,000 samples/ second |

| Trace Time: | 0.1 – 60 seconds, Infinite, Rot-Sync |

| Charts: | x/y, t, x/y + t, C-scan |

| Thresholds: | Lines, circle, box, sector |

| Freeze Mode: | Freeze your signal and adjust parameters like gain and phase |

| Documentation: |

|

| Array Technology: | Up to 512 probe elements |

| Supported Probes: |

|

| Conductivity Measurement Frequency: | 60, 120, 240, 480 kHz |

| Conductivity Measurement Accuracy: | +/- 1.0s% of measured value at 60 kHz, 14 mm probe |

| Conductivity Measurement Resolution: | +/- 0.1% of measured value |

| Conductivity Measurement Range: | 0.5 to 65 MS/m (1-112% IACS) |

| Wizards: |

Auto-set wizard for:

|

| Fulfilled Standards: |

DIN EN ISO 15548 |

To purchase the TCM, please contact us here: