Overview

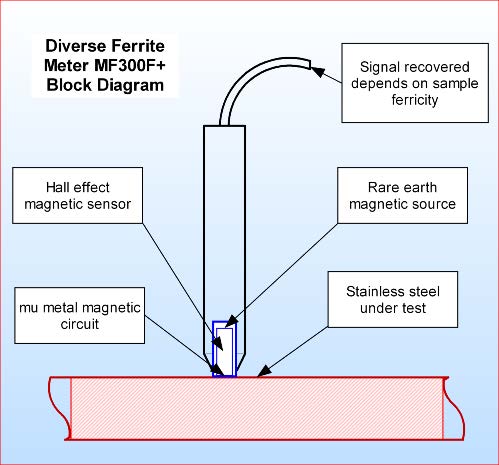

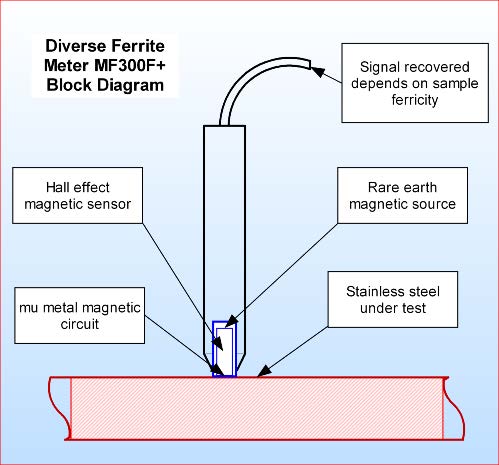

The MF300Fm+ is the latest instrument from Diverse Technologies, and an upgraded version of its predecessor, the MF300Fe+. The MF300Fm+ measures the Ferrite number (FN) of austenitic and duplex stainless steel weld material, and can be operated with 3 probes simultaneously. The robust, slimline probe benefits from a novel magnetic system with excellent coupling to a measurement sample, that is sensitive to ferrite content in 10mm area to a depth of approximately 1mm. An air cooled version of the probe (must be specified at time of order) allows Ferrite measurements on hot samples as well.

The MF300Fm+ can store up to 1000 measurements including record number (0 - 999), measured ferrite number and recorded ID (4 characters, 0-9, A-Z and space). You can download or upload these measurements to a PC via RS232 or USB (optional).

The instrument is calibrated used the secondary weld standard validated by NIST in the USA. All 16 standards are used in calibration with a measurement range from 0 - 115 FN. Transfer standards are supplied with the instrument allowing performance to be verified at any time.