| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| HAWKEYE 2000 Weld Scanning System for Crack Detection | EC-TET-HAWKEYE-2000 |

|

Request Pricing | ||

TesTex HAWKEYE 2000 Weld Scanning System for Crack Inspection

Using the Balanced Field Electromagnetic Technique (BFET), TesTex's Hawkeye crack detection system detects surface & subsurface cracking through paints, coatings or scale. With scanning speeds from a few inches per second up to a foot per second, the Hawkeye is much faster and more thorough than traditional NDT techniques.

See video here.

A revolutionary technique has been developed for the detection of cracks in welds and other materials.

TesTex introduces one of the most innovative systems for the detection and sizing of both surface and sub-surface toe-cracks in welds and base metals. Although the current system and geometric configuration is most suited for the inspection of lap welds in storage tank plates, the system is easily adjustable for the detection of toe-cracks in other welds such as butt, toe, fillet, etc. This system is based on the eddy current principles of electromagnetic techniques and replaces the old and laborious techniques such as vacuum box, dye penetrant or magnetic particle inspections. This technique is quantitative and gives the depth and length of cracks. Unlike UT, the system does not demand a clean surface and is forgiving to scale, corrosion products, etc. With scanning speeds up to 1 ft. / second, the system is fast, accurate and efficient for the evaluation of toe-cracks in welds.

Advantages:

|

Features:

|

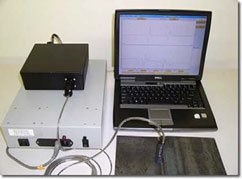

The Hawkeye 2000 DSP (Digital Signal Processing) with multi-channel electronics

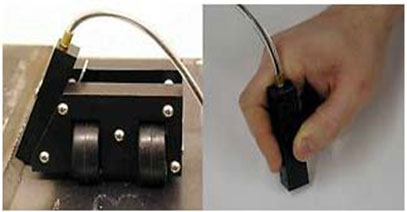

Picture above shows some different Hawkeye Probe designs

A lap-weld being scanned using the Hawkeye 2000

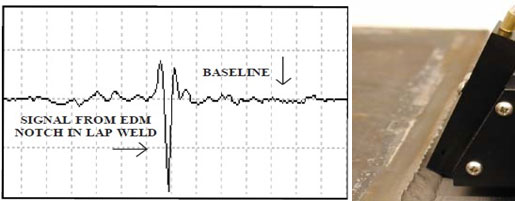

Example of Typical Defects:

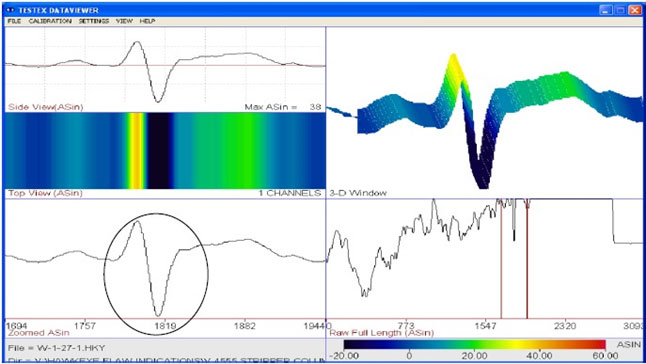

Flaw signal from a sub-surface 6mm EDM notch incorporated into a lap-weld. Plate thickness is 0.375".

Scanning speed is approximately 1 ft. / second

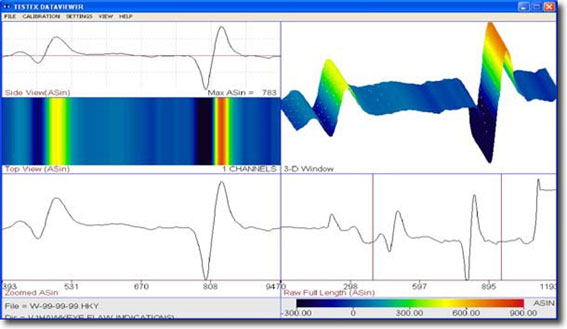

The waveform above was collected using a traditional Hawkeye Probe. Both cracks are 0.008" wide with the

first cracking at 0.083" deep and the second cracking at 0.150" deep.

The waveform above was collected using the traditional Hawkeye Probe. This data was collected on a Column during the

2008 ConocoPhillips Turnaround. The sharp up and down signal is a crack indication.

Software Representations:

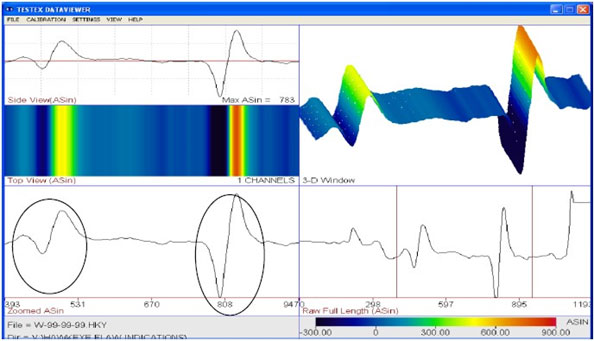

The Hawkeye 2000's "Hawkeye" software package contains modules for Data Acquisition, 3D Full Color Data Display, Quick View Analysis and Advanced Digital Signal Processing. This provides crack detection and gives the depth and length of cracks.

Software Features:

|

Full screen view of the display software with defects including side view, top view, channel processed

window, 3D view and raw data window.

Versatility:

|

System and Technical Specifications

System Specifications:

|

Electronics:

|

Probes:

Measuring Technique: Balance Field Electromagnetic Technique (BFET)

Maximum Penetration: 0.375" (9mm) carbon steel

Number of Sensors / Channels: 1 to 8

Inspection Width: 12mm per channel

Scanning Speed: 12 inch / second or 305mm / second (Max.)

Probe Types:

|

Dimensions: (varies with application):

| Height: 0.5" (12mm) - 3.5" (89mm) Length: 1" (25.4mm) - 5" (127mm) Width: 1" (25.4mm) - 4" (102mm) |

Weight (varies with application): 5 oz - 1.5 lbs. (0.14 - 0.7 kg.)

The components above are used with a standard scanner, cable, serial port connector, 110 / 220 VAC power cord. It is easily packed for transport and can be taken anywhere inside the plant.

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| HAWKEYE 2000 Weld Scanning System for Crack Detection | EC-TET-HAWKEYE-2000 |

|

Request Pricing | ||