| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Eagle 2000 Plus Multichannel NDT System for Tube Inspection from the I.D | EC-TET-EAGLE-2000-PLUS |

|

Request Pricing | ||

TesTex Eagle 2000 Plus Multichannel NDT System

The Eagle 2000 Plus Multichannel NDT System is a fast, accurate, cost effective and field proven system for tube examination from the I.D. It can be used in single channel mode, differential mode, or multichannel mode depending upon the type of inspection required. A full 100% circumferential test is performed over the tube's full length, not just the finite points, as with some other NDT methods. The Eagle 2000 Plus detects and quantifies corrosion, erosion, pitting, cracking and mechanical defects by using the remote field electromagnetic technique (RFET) method, preventing costly and dangerous tube failures. The Eagle 2000 Plus tests straight and U-Bend heat exchanger tubes, bent boiler tubes, finned or unfinned tubes, ferrous or non-ferrous tubes and small diameter pipes. It also provides a baseline evaluation of new or stock tubes.

Features & Advantages:

|

System Versatility:

|  |

Full Length Boiler Tube Inspection

Boiler inspections are performed on drum to drum type boilers as well as straight tube boilers. These tests are full length examinations from the tube I.D. giving quantitative evaluations of each tube. Applications include power boilers, recovery boilers, waste heat boilers, fire tube boilers, dowtherm boilers and related boiler components such as tubular air heaters. With the flaw characterization process, defects such as areas of wall thinning, pitting, cracking, erosion / corrosion, soot blower thinning and flue gas thinning are exposed and evaluated.

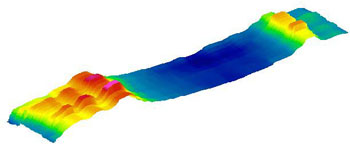

Probe insertion / retraction from a boiler steam drum |  3D representation showing 65% to 70% wall loss near the mud drum bend |

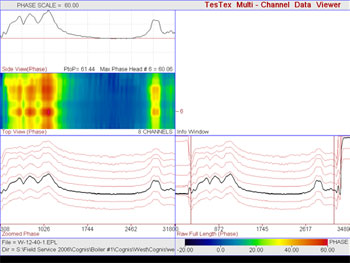

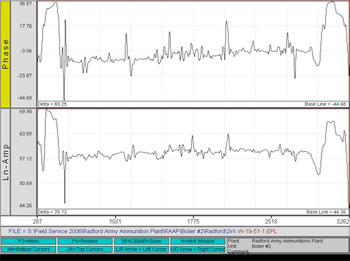

Multichannel drum to drum boiler data showing 65% to 75% wall loss near the mud drum bend |  Single channel drum to drum boiler data showing 35% to 45% wall loss. |

Heat Exchanger Tube Inspections

Heat Exchanger inspections are performed on straight shell and tube exchangers, U-Bend bundles and finned tube exchangers. Applications include feedwater heaters, air coolers / fin fans, chillers / coolers, air heaters / pre-heaters, MSR's, reformers / ultraformers, condensers, reactors and reboilers. Types of defects located in these units are wall thinning, pitting, cracking, vibration / fret wear, erosion / corrosion and steam cutting.

Single Channel and Multichannel

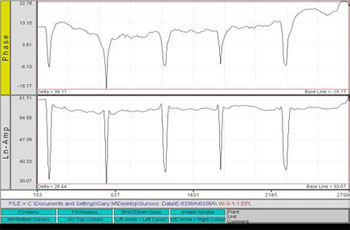

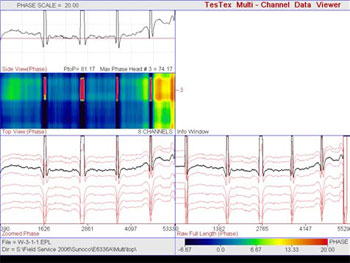

Single channel heat exchanger data showing wall thinning near the tube sheet |  Multichannel view of the same waveform showing wall thinning near the tube sheet |

Software Features:

|

Design Features:

|

Detection Capabilities:

Using a standard 8 channel rigid probe, a 0.039" (1mm) diameter pit, 30% deep, can be detected in a 1" O.D., 0.083" wall carbon steel tube. Other small defects such as circumferential and axial cracks can be detected and quantified using a calibration standard prepared with EDM notches. All defects are sized by phase and amplitude response and number of channels affected.

Specifications:

| Electronics: | |

| Electronics Base: | Digital / DSP based |

| Frequency Range: | 5Hz to 30KHz |

| Channels: | 1 to 8 channels |

| Power Consumption: | Max 15VA |

| Line Voltage: | 110 or 240 VAC at 50 or 60 Hz (self adjusting) |

| Dimensions: | 13" x 11" x 3.5" / 330 x 290 x 90 mm (LxWxH) |

| Weight: | 5 lbs. / 2.25kg |

| Probes: | |

| Channels / Sensors: | 1 to 8 channels provided by 1 to 16 sensors |

| Sizes: | Start at 0.250" (6mm) |

| Length: | U to 100ft. (30m) with no amplification* |

| Method: | RFET (Remote Field Electromagnetic Technique) |

| Fill Factor: | As Low as 40% |

*Longer probes can be made with amplification

Materials Tested:

Carbon Steel, Cast Iron, Chrome Moly, Stainless Steel, Nickel, Copper, Brass and other various alloys.

The system is operated using a laptop PC acquiring data through its serial port connection. The modular system is easily packed and can be taken anywhere within the plant.

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Eagle 2000 Plus Multichannel NDT System for Tube Inspection from the I.D | EC-TET-EAGLE-2000-PLUS |

|

Request Pricing | ||