| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Demagnetizing Applications | DE-MM-DEMAG-APPS |

|

Request Pricing | ||

Maurer Demagnetizing Applications

Demagnetizing of Engine and Gear Parts

Processes used in the manufacture of modern engines and gear parts include eddy currents, coating, grinding and machining processes. In this process chain, residual magnetism often intrudes as an invisible enemy and saboteur. Residual magnetism can lead to re-magnetization of the whole part within a short time.

We offer our customers in this area of application tailored equipment and many years' experience in finding the optimal solution for the demagnetization of parts. Demagnetizing systems can be used both manually and in automated applications. Our own engineering team also develops individual solutions for special applications.

Magnetizing of Machines and Modules

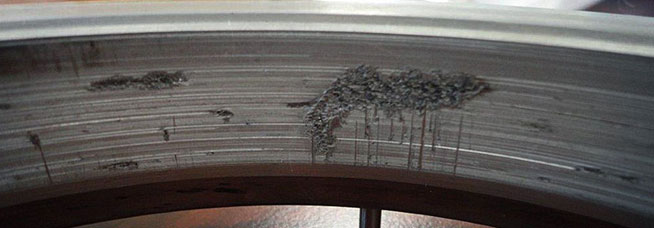

Too much magnetism in the components of punch presses, powder presses, press brakes, lapping machines, CNC machines and many other production machines interferes with their operation and has a negative influence on the quality of the parts. This magnetism causes the sintering powder in powder presses to adhere to dyes and stamps, leading to density fluctuations of the green compacts. With magnetic lapping machines (lapping stones), stronger abrasion of the parts lead to grooves and scratches on the surface of the parts being treated.

In large compressors and turbines residual magnetism causes premature failures and unbalance in bearings and also sometimes faulty concentricity measurements with the eddy current method (Bently-Nevada).

Maurer Magnetic offers demagnetizing machines specially developed for these purposes. Alternatively, you can use our demagnetizing services, either on-site at your location or in our demagnetizing laboratory.

For more information, click on the link - Demagnetizing Services

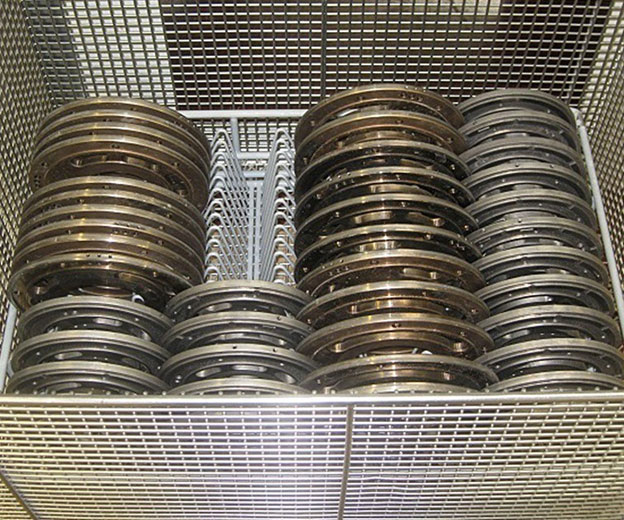

Demagnetizing of Roller Bearings and Slide Bearings

Too much residual magnetism in roller bearings and slide bearings can cause damage in many different ways:

|

To counteract these effects, Maurer Magnetic offers specially-developed machines for the demagnetizing of individual bearing parts and also for complete, assembled bearings.

For more information, click on the link - 36 Bearings

Demagnetizing Buildings and Infrastructure

For the safety of personnel, radiation therapy equipment in hospitals are now enclosed in reinforced concrete walls up to two meters thick. Residual magnetism in the reinforcing rods can exert a massive influence ont he function of the electron beam therapy. To avoid this, all walls of the room have to be fully demagnetized.

The same method can be used to demagnetize rooms in private buildings. In recreation and sleeping areas, magnetized reinforcing rods distort the earth's natural magnetic field.

Residual magnetism in rails can cause transmission errors in systems in which signals are transmitted via the rails. For instance, electromagnetic rail brakes magnetize the rails. This can then lead to errors (emergency braking), depending on the speed of the train. Maurer Magnetic offers the optimum solution for all individual applications.

For more information, click on the link - Mobile Demagnetizer

Demagnetizing Prior to Welding

The phenomenon of magnetic arc blow, well known to experts, results in deflection of the arc during welding. This phenomenon can already be observed with residual magnetism values of 10-20 A/cm, depending on the welding method used (WIG, MIG / MAG, etc..). With electron beam processes (EB welding, EB hardening), very low levels of residual magnetism also influence the precise direction of the electron beam.

The components to be welded, as well as the tool holders, have to be demagnetized to the lowest possible value. Maurer Magnetic offers a broad range of products for industrial customers - for mass production, for individual manual applications and for emergencies (i.e. work stoppages at construction sites due to welding problems).

For more information, click on the link - Demag of Large Objects Before Welding

Demagnetizing Small Parts and Precision Parts

Injection needles in medical technology are handled in containers holding several thousand pieces. In-order to carry out further processing of the needles, it has to be possible to separate the individual needles. Residual magnetism can interfere with the process because several needles "stick together" during handling or separation.

When mounting precision parts in the watch industry or in micro engineering, disruption is caused by even the weakest magnetic fields, because the parts adhere to the tools.

Thanks to many years' experience in this area, Maurer Magnetic can provide the optimal demagnetizer for your application.

For more information, click on the link - High Precision Demagnetizer MM DN+KE

Demagnetizing Hard Metal Tools and Parts

Hard metal tools undergo cleaning and coating. In both applications, residual magnetism plays a decisive role. For one thing, an increase in magnetism causes adherence of minute particles; for another, residual magnetism influences the PVD coating process at the surface of the part (fluctuations in coating thickness, etc..)

Residual magnetism in tungsten carbide machining tools is undesirable for end customers because particles or shavings adhere to the tools and have a negative influence on the production process. Whether miling, drilling, reaming, shaping or forming, whatever process is involved, Maurer Magnetic offers you the optimal demagnetizing solution.

For more information, click on the link - General Demagnetizers

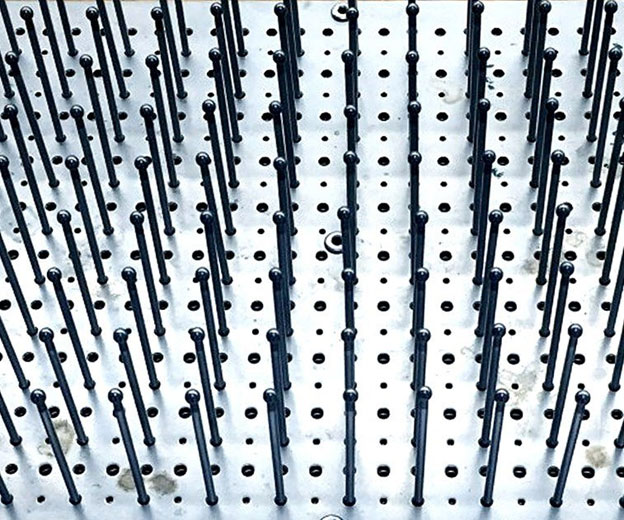

Demagnetizing Parts in Racks

For cleaning processes with stringent residual dirt requirements, parts need to be demagnetized before washing. In high performance demagnetizing machines, racks loaded with parts can be demagnetized efficiently with just one pulse.

Producers are increasingly confronted with requirements for low residual magnetism limit values and they are looking for a reliable process to demagnetize their products; with Maurer Degaussing® whole racks or boxes of parts can be demagnetized before delivery.

For more information, click on the link - Demagnetization Prior to Parts Cleaning MM DN+SE

Demagnetizing Bulk Goods

In order to remove ferromagnetic particles completely in the washing process, and in order to comply with limit values for residual magnetism, parts have to be thoroughly demagnetized. However, with conventional demagnetizing methods, parts in the middle of the bulk goods are shielded from the demagnetizing field by the surrounding parts, and due to the relatively weak field strength demagnetizing is insufficient.

With Maurer Degaussing® technology, the extremely strong alternating magnetic field penetrates the bulk goods throughout, independently of the quantity and the orientation of the parts. Bulk material is demagnetized within a few seconds by a reinforced "Field Multiplicator Technology" demagnetizing pulse.

Demagnetizing with Small Machines and Hand-Held Devices

By direct contact, hand tools like screwdrivers and pliers can transmit magnetism to a component or machine which has previously been demagnetized. Manufacturers of these products need to ensure that their tools can be tested for magnetism and demagnetized if necessary.

With the MM JE series, Maurer Magnetic AG offers a demagnetizer which is uniquely suited for applications of this kind. Small components and flat components can also be successfully demagnetized with these devices, either manually or in a continuous process.

When correctly used, surface magnetism of large components can be reduced with a hand demagnetizer.

For more information, click on the links - Yoke Demagnetizer MM JE, Handheld Demagnetizer MM HE

Degaussing Parts for Cleaning

For more information, click on the link - Demagnetization Prior to Parts Cleaning MM DN+SE

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Demagnetizing Applications | DE-MM-DEMAG-APPS |

|

Request Pricing | ||