| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

Instrument Kits |

|||||

|

BAQ AlphaDur Mini II Kit with Probe (select test load)

Model #

|

HT-BAQ-14-102-Master |

|

$6,895.00 | ||

| BAQ AlphaDur Mini II Main Unit and SL Probe (0.7" shaft length) with test load (specify load) | HT-BAQ-14-102-129A |

|

$7,075.00 | ||

| BAQ AlphaDur Mini II Main Unit and SL Probe (1.3" shaft length) with test load (specify load) | HT-BAQ-14-102-129B |

|

$7,225.00 | ||

Separate Probes |

|||||

|

BAQ Separate Standard UCI Probe (select test load)

Model #

|

HT-BAQ-14-Master |

|

$3,450.00 | ||

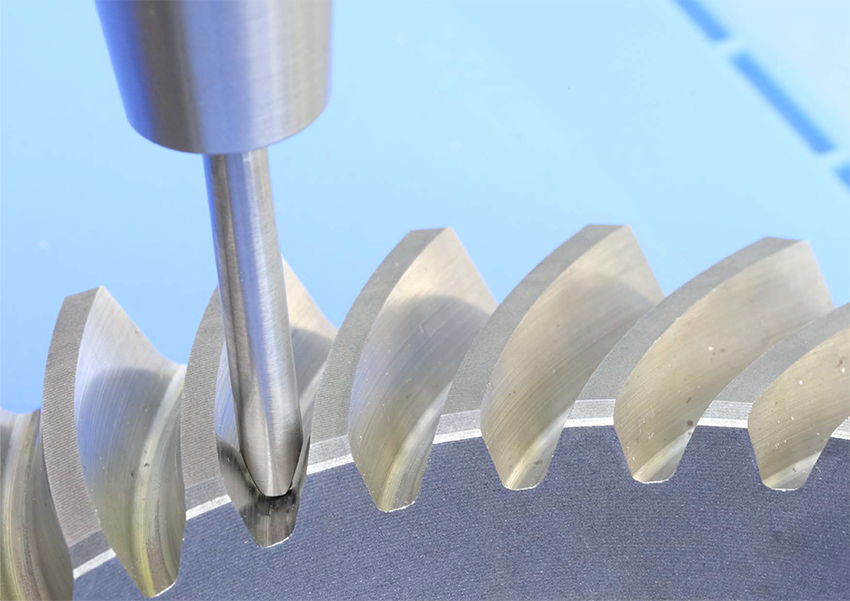

| BAQ Special probe SL for measurings e.g. in drill holes or cogwheels (Tooth base) Shaft diameter / length: 5 mm / 18 mm Available test loads: 3N, 10N, 20N, 30N, 49N, 98N | HT-BAQ-14-129A |

|

$3,895.00 | ||

| BAQ Special probe SL-L for measurings e.g. in drill holes or cogwheels (Tooth base) Shaft diameter / length: 5 mm / 34 mm Available test loads: 3N, 10N, 20N, 30N, 49N, 98N | HT-BAQ-14-129B |

|

$4,065.00 | ||

Probe Accessories |

|||||

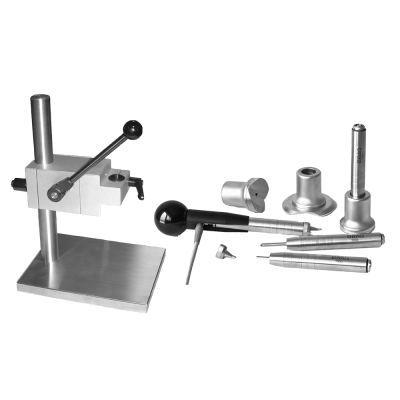

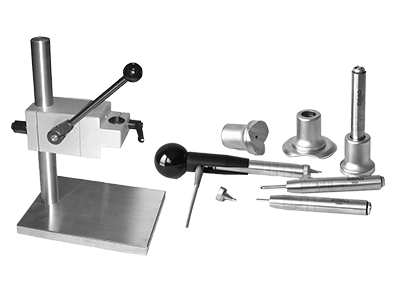

| BAQ High Precision Stand | HT-BAQ-11-130 |

|

$1,860.00 | ||

| BAQ Probe Support for Flat Specimen | HT-BAQ-11-131 |

|

$610.00 | ||

| BAQ Probe Support for Round Specimen 10 -50 mm (0.4 - 2") | HT-BAQ-11-132 |

|

$650.00 | ||

| BAQ Probe Support for Round Specimen 50 - 250 mm (2 - 10") | HT-BAQ-11-133 |

|

$670.00 | ||

| BAQ Handle for the probes with ball knob | HT-BAQ-11-142 |

|

$180.00 | ||

| BAQ Protective Sleeve for Probe (Screwed on the probe for protection of the UCI-Rod) | HT-BAQ-11-171 |

|

$165.00 | ||

| BAQ Probe Cable | HT-BAQ-11-172 |

|

$280.00 | ||

Test Blocks |

|||||

| BAQ Hardness Test block for UCI, Rockwell Calibration with ISO and ASTM certificate (specify hardness value: approx. 20, 30, 40, 50, 55, 60, 65 HRC) | HT-BAQ-HVP-9016HRC-EP |

|

$735.00 | ||

| BAQ Hardness Test block for UCI, Vickers Calibration with ISO and ASTM certificate (specify hardness value: approx. 240, 300, 400, 510, 600, 700 or 830 and Test Load: HV0.3, HV1, HV2, HV3, HV5, HV10) | HT-BAQ-HVP-9016HV-EP |

|

$735.00 | ||

Additional Accessories |

|||||

| BAQ Power Supply / battery charger + Adapter for Charger (US/CA) | HT-BAQ-12-173 |

|

$205.00 | ||

| BAQ Calibration of the probe including certificate (shipping costs not included) | HT-BAQ-R-S-KAL |

|

$330.00 | ||

| BAQ DAkkS-Calibration of a UCI-Hardness Tester with one Probe according to DIN 50159 by an accredited laboratory | HT-BAQ-R-AD-KAL-DIN |

|

$660.00 | ||

| BAQ DAkkS-Calibration of a UCI-Hardness Tester with one Probe according to ASTM A1038 by an accredited laboratory | HT-BAQ-R-AD-KAL-ASTM |

|

$660.00 | ||