| # of Channels |

1 |

| Probe Connector Type |

LEMO 00 |

| # of Probe Connectors |

2 |

| Max Supporting Elements |

2 |

| Work Mode |

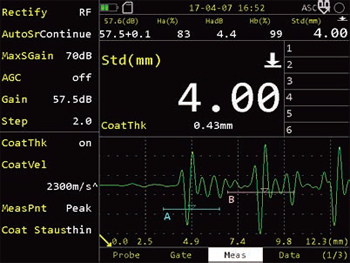

Standard (R-B1, measurement from transmit pulse to the first bottom wave). All measurements using Zero Crossing.

Echo to Echo (B1-B2, measurement by auto-tracking the second bottom wave according to the first wave).

Through-coating measurement. |

| Pulse |

Negative Square, Negative spike pulse (auto fits the probe) |

| Transmitting Voltage |

50 - 350V (auto fits the probe) |

| Pulse Width |

Negative Square: 50-500ns (auto fits the probe)

Negative spike pulse: ≤40ns (auto fits the probe) |

| PRF |

200Hz |

| Damping |

50/1000Ω, 2 levels (auto fits the probe) |

| A/D Sampling |

240MHz / 10bit |

| Sampling Point |

1024 points, 16bit/point |

| Gain |

0-110dB

Manually adjustable step: 0.5/2/6/12dB

Auto adjustable (auto-search or auto-gain) |

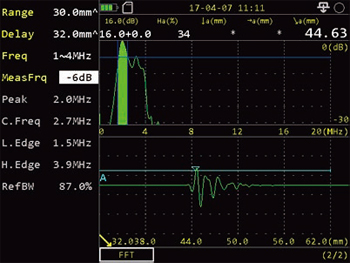

| Bandwidth |

0.5 - 20MHz (-3dB) |

| Operating Frequencies |

1-4MHz / 0.5-10MHz / 1MHz / 2.5MHz / 4MHz / 5MHz / 10MHz / 13MHz / 15MHz / 20MHz, 11 levels |

| Rectify |

Negative / Positive / Full / RF |

| Reject |

0-80%, step 1% |

| Detection Range |

0.02"-24" (0.5-600mm) subject to probe, material, temperature and selected configuration) |

| Indication Resolution |

0.0001" / 0.001" / 0.01" (0.001 / 0.01 / 0.1mm) |

| Indication Precision Error |

0.03"-0.4" ± 0.002" (0.80-9.99mm ± 0.05mm)

0.4"-4" (10.00-99.99mm ± (1%H + 0.04)

4"-16" (100.00-400.00mm) ± 3%H

Tested with TGM5-10L Probe; H is the measured thickness. |

| Tube Wall Thickness |

With TGM5-10L probe, it can measure steel tubes with diameters no less than 0.8" (20mm) and wall thickness no less than 0.08" (2mm) |

| Material Velocity |

100-20000m/s |

| Display Range |

0.2"-40" (5-1000mm) |

| Pulse Shift Range |

-0.4"-20" (-10-500mm) |

| Probe Zero |

0-200us |

| Gate Mode |

Gate A is selected in standard measurement mode |

| Gate Start |

Gate A start: -0.4"-4" (-10-1000mm), min step 0.004" (0.1mm) |

| Gate Width |

Gate A width: 0.04"-4" (1-1000mm), min step 0.004" (0.1mm) |

| Gate Thresh |

Gate A thresh: 10-90% or -10-90% (for RF), step 1% |

| Auto Search |

Off/on; if enabled, auto adjusts to proper display range, gain and gate position based on the measured wave signals, to improve measurement efficiency. |

| Velocity Measurement |

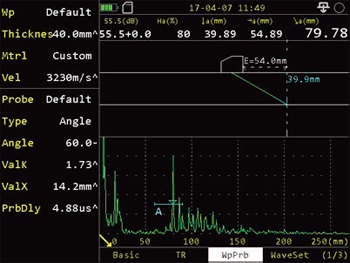

Velocity dynamic measurement |

| Calibration |

Measure the known reference block for fast zero point calibration.

Custom calibration (zero point / zero point + velocity calibration) |

| Measurement Reading Mode |

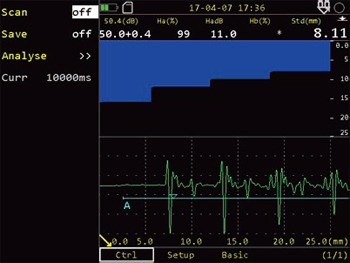

Std / MinVal / MaxVal / Avg / Diff |

| Alarm |

Upper and lower limit alarm (sound, indicator light) |

| Screen Display Combination |

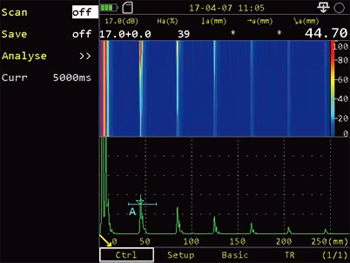

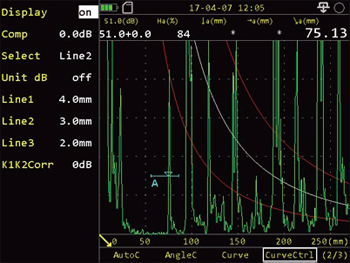

A/BVa, A/Ba/SVa, Ba/BVa (A-Scan + big value / A-Scan + data grid + small value / data grid + big value) |

| Refresh Rate of Measurement |

4/8/16/32Hz |

| Axiliary Function |

Freeze, auto gain, history reading column, last reading maintained, inch / mm switch, outdoor mode. |

| Storage Function |

Save, recall and delete parameter, data sets, printscreens, depends on the SD card capacity. |

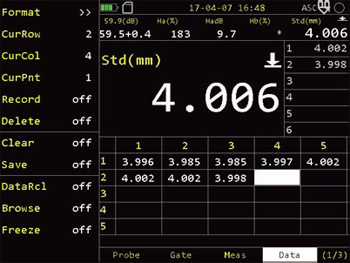

| Dataset File |

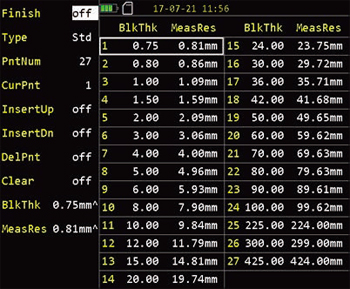

1D/2D/3D file format

Measurements recorded and displayed in grids; record length customizable.

Each record point data includes measured values, basic parameter settings and A-Scan waveform data. |

| Data Post Processing |

Playback, analysis, reports of parameters, data sets, printscreen files in SuporUp software. |

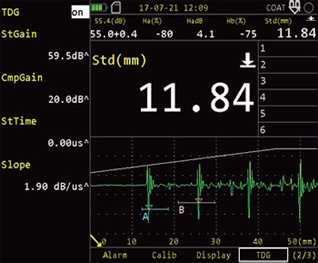

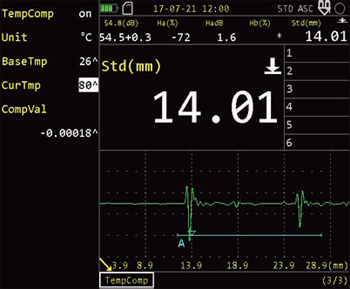

| Optional Software |

CoatTHK, V-PATH, TDG, Temperature Compensation, Multi-layers measurement, B-Scan. |