Two Models

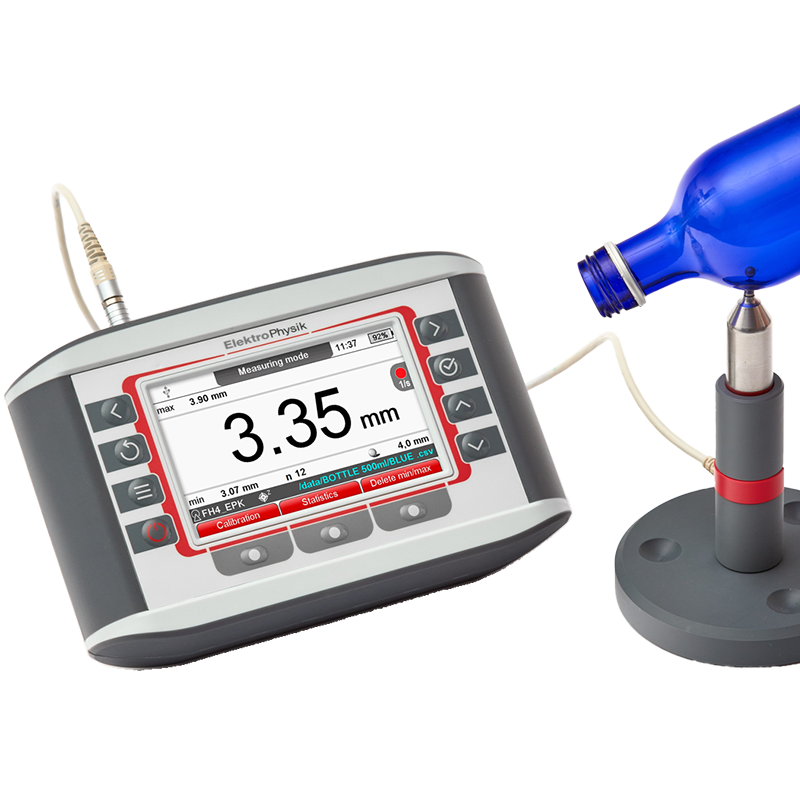

MiniTest 7200 FH offers measurement capabilities including real-time thickness measurement, display of minimum and maximum readings, an offset mode and automatic storage of up to 100,000 values. MiniTest 7400 FH offers the same capabilities as the MiniTest 7200 FH plus statistical graphing, real time trend, data base with up to 200 batches and a larger memory for automatic storage of up to 240,000 readings, e. g. 1,200 readings per batch.

Five Sensors

Easily interchangeable sensors with a hardened tip and a variety of ball sizes are available to cover the various thickness ranges. The FH 4 type sensors use steel balls to measure from 0 to 6 mm and magnetic balls to measure up to 9 mm. A special FH 4 sensor allows to work with a 1mm steel ball which can be introduced in small cavities. The FH 10 type sensors use steel balls to measure from 0 to 13 mm and magnetic balls to measure up to 24 mm. All sensor models are interchangeable and can be connected to any of the two gauge models.