Optional Probe Tracking & 3D Visualization Software

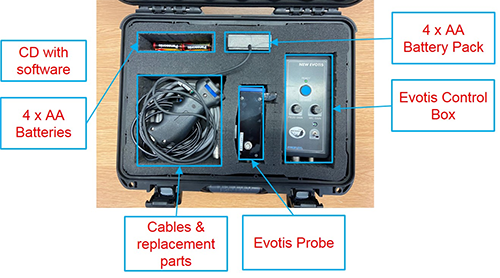

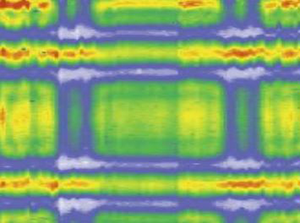

TWI have developed an automated tap-test system based on a modified Evotis unit & bespoke software for data acquisition, signal processing & visualization. The system allows inspection of large areas, including complex GFRP structures. The software automatically tracks the position of the probe & records the responses from the unit, digitally processes them & displays the results in the familiar “heat map” or cscan type format.

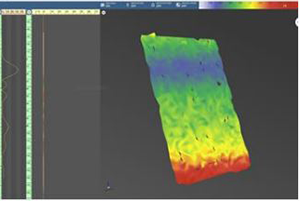

Fully automated inspection enable 3D visualization of the results, overlaid onto a CAD model of the structure. This allows easy interpretation and analysis of the results and mapping of defects, anomalies and indications for lifetime records and future reference. The System has been trialed on a number of structures with excellent results.