| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| TX-4400 ECT Inspection System | EC-TET-TX4400 |

|

Request Pricing | ||

TesTex TX-4400 ECT Inspection System

The TesTex TX-4400 ECT Inspection System is based on the Eddy Current Technique, to quickly and accurately inspect non-ferrous metal tubing from the I.D. By using 4 frequencies in a simultaneous injection mode, defects such as ID / OD pitting, baffle cutting, erosion, steam impingement and general wall thinning can be detected and sized. The system also has differential and absolute responses for each frequency, a built-in reference signal to generate an absolute signal without the use of a reference probe and real-time mixing for suppression of support / baffle plates. The system can be used in conjuction with our TS-Map and AR-Wizard software, so a final report can be delivered on-site.

The TX-4400 system uses both DSP and FPGA technologies to enhance performance capabilities while maintaing low cost and size. Utilizing easily configured and readily available USB technology, the TX-4400 interfaces to any windows based PC / notebook. All data is archived for analysis and processing, as well as for future inspections and trending. The electronic boards are designed for independent operation to permit easier troubleshooting, repair and expansion. Each of the main circuit boards is designed to act as a nearly complete single frequency system. More frequencies can be added to a system by inserting additional circuit boards to the backplane board.

Depending on the configuration, the TX-4400 offers either high-speed inspection, which provides maximum speeds of five feet per second (1.52m/sec.) or ultra-high speed insertion, which has a maximum speed of 20 ft. per second. Probes may be driven manually or with one of the 2 optioanl probe drivers: the PD 6k or the PDP 22. Both connect directly to the TX-4400 and use the same software and are durable and reliable.

Advantages and Features:

|

Options:

|

Technical Specifications:

| Electronic Base: | Digital-DSP / FPGA based |

| Frequencies: | 4 simultaneously |

| Power Consumption: | Maximum 15VA |

| Line Voltage: | 110 / 220 VAC (self adjusting), 50 / 60 Hz or 12 VDC |

| Dimensions: | 11" x 13.25" x 6" (279 x 337 x 152 mm) |

| Weight: | 10 lbs. (4.5 kg.) |

Software

Software Features:

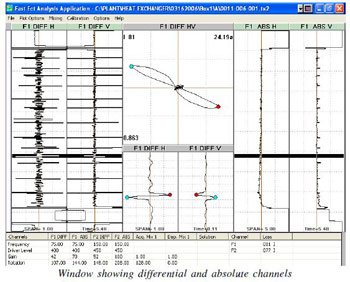

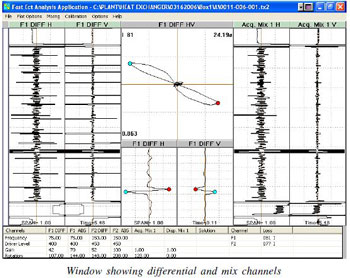

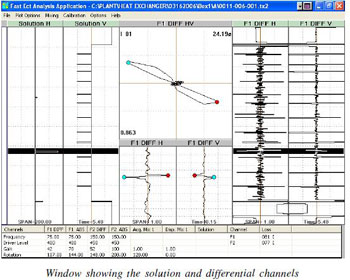

TesTex has developed a complete and user friendly software package to enhance any eddy current inspection. From acquisition to the final report, this software has it all. If increased productivity and less man hours is what you are looking for, then the addition of modules such as TX-SOLUTION, TX-MAP and AR-WIZARD is your answer.

Acquisition:

|

Analysis:

|

|  |

Auto Analysis (TX-SOLUTION):

|

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| TX-4400 ECT Inspection System | EC-TET-TX4400 |

|

Request Pricing | ||