G & R HT-1000A / 2000A Leeb Hardness Tester

Features:

- Highly accurate

- Easy to use

- Suitable for testing a variety of materials

- Compact and lightweight, perfect for testing materials on-site

- User friendly monitor clearly displays test results; readings in HL, HV, HB, HRB, HRC or HSD hardness scales

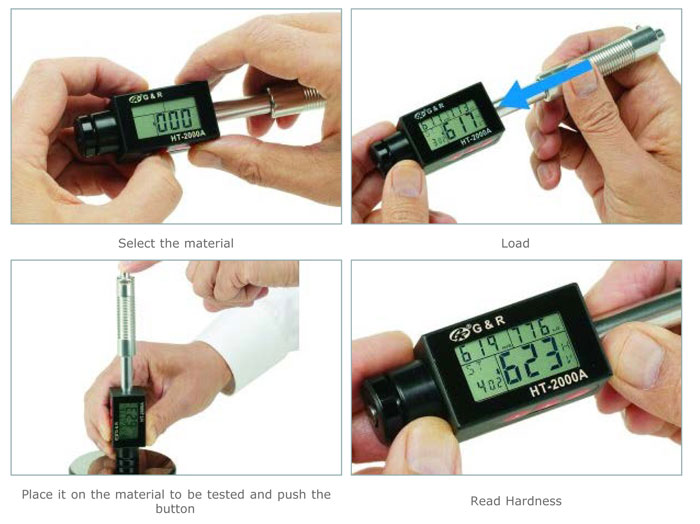

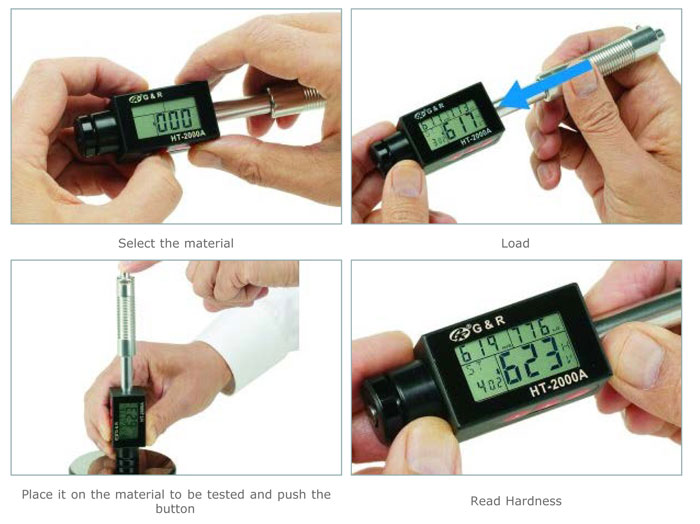

Operation:

Operation of the HT-1000A/ HT-2000A is easy and test results can be obtained in just seconds. To obtain a reading, simply load the test, position it on the material and push the button. Setting up the instrument is also very simple. Two function keys are used to select up to 10 materials, 6 hardness scales and 5 testing directions.

| Application: The HT-1000A and HT-2000A have many applications in the primary metals, metal fabrication, utilities and petroleum, chemical, automotive and aerospace industries. Their small size and easy to use, one-handed operation makes them ideal for testing large and heavy forgings or castings, such as steel mill rolls and turbine housings. Also, due to their small size and portability, the testers can be used to test individual parts of a large assembly without taking the finished assembly apart. The testers can be used vertically or horizontally and require only a small surface area to obtain a quick and accurate reading. These versatile testers can be easily used by anyone, anywhere, to obtain direct accurate hardness readings. |  |

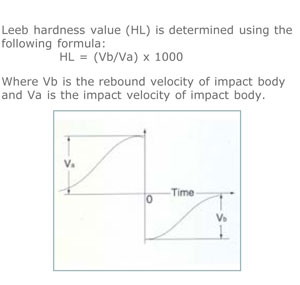

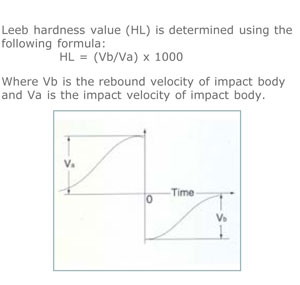

| Principle: The HT-1000A and HT-2000A hardness testers operate on the Leeb principle, a dynamic hardness test method based on velocity measurement. They include a guide tube and an impact body. The impact body contains a magnet and tungsten-carbide ball, measurements are performed using a spring to propel an impact body through a guide tube towards the test surface. When the ball is within 1mm of the part's surface, the magnet induces a voltage into a coil surrounding the guide tube. After penetration, the impact body rebounds and the magnet returns through the coil inducing a second voltage. Both voltages are proportional to the velocity of the impact body. |  |

Specifications:

Testing Range:

200 - 900 HL (Leeb Value)

Scales:

HL, HV, HB, HRB, HRC and HSD

UTS:

Kgf/cm2, Tons/in2, Lbs/in2, (HT-2000A only)

Accuracy:

± 4HL

Testing Direction:

Any Direction

Materials:

Low carbon steel, high alloy steel, stainless steel, gray iron, nodular iron, aluminum, brass, bronze and copper

Operating Temperature:

14°F to 104°F (-10°C to 40°C)

Storage Temperature:

4°F to 122°F (-20°C to 50°C)

Batteries:

Tester: Two 3V Lithium CR-2330 Batteries

Printer: Rechargeable Li-Lon Battery

Battery Life:

Test work life: 40 hours continuous (2,500 test results)

Shelf life: 2 years

Printer:

10,000 lines / once fully charged

Data Storage:

Automatically records up to 200 test results including readings, conversions, average values, hardness scales, material, direction, date and time

Date and Time:

Real time and date with a 10 year calendar.

Tester Dimensions:

60.5" (165mm) x 1.1" (28mm) x 1.1" (28mm)

Contact Diameter:

0.79" (20mm) and 0.53" (13.5mm)

Weight:

4.2 ounces (120 grams)

HT-1000A Contains:

- Standard Test Block

- Support Ring 0.79" (20mm)

- Support Ring 0.53" (13mm)

- Plastic Carrying Case

- Tube Cleaning Brush

- Two (2) CR-2330 Lithium Batteries

- Operating Manual

HT-2000A Contains:

- HT-2000A Hardness Tester

- Standard Test Block

- Support Ring 0.79" (20mm)

- Support Ring 0.53" (13mm)

- OM-6240 Infrared Printer

- Two (2) CR-2330 Lithium Batteries

- Operating Manual

- Plastic Carrying Case

- Tube Cleaning Brush