| Testing Index |

| Attenuator |

Every 20dB ±1dB |

| Vertical Linearity Error |

≤ 3% |

| Dynamic Rebound |

≥ 32dB |

| Horizontal Linearity Error |

≤ 0.5% |

| Pulser |

| PRF |

10 steps (20-500Hz adjustable but subject to detection range, material velocity, pulse shift and probe delay.) |

| Damping |

Low / High, 2 steps (1000/500) |

| Receiver |

| Operating Frequency Range |

0.5 - 8 MHz |

| Reject |

0 - 80% |

| Gain Adjustment |

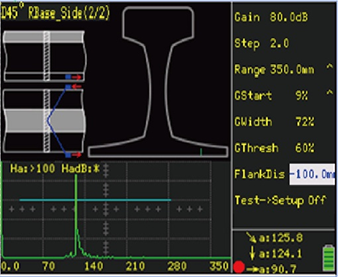

Range: 0 ~ 110dB; Adjustable steps: 0.5 / 2 / 6 / 12 dB |

| Measurement |

| Detection Range |

0 - 13000mm (Longitudinal wave in steel) |

| Pulse Shift Range |

-10 ~ 1000mm (Longitudinal wave in steel) |

| Auxiliary Function |

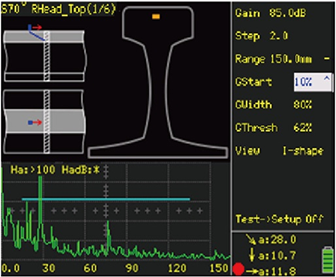

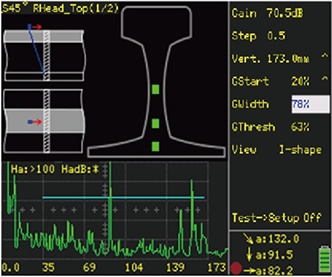

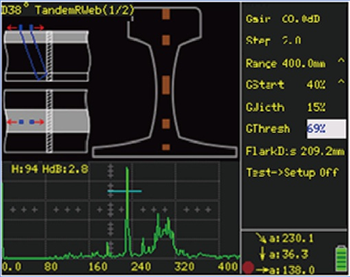

Coordinate switch(sound path/depth/horizontal), freeze, auto gain(40%-100%, step:10%), peak envelop, wave compare, zoom, gate expansion, screen shot, adjustable filtering, cineloop, wave filling, rail type selection(38/43/50/60/70 kg/m), weld I-shape mark (auto/manual), B scan image |

| Angle Measurement |

Measure probe angle |

| Material Velocity |

400 - 15000 m/s |

| Probe Zero |

0 - 200 μs |

| Auto Calibration |

For calibrating material velocity and probe delay. Calibration mode: Velocity and Zero |

| DAC Curve |

For making, setting and applying DAC curves. |

| Gate |

| Gate |

Gate Start: 0 - 109%

Gate Width: 1 - 109%

Gate Thresh: 10 - 90% |

| General Technical Specifications |

| Display Screen |

5.7" high brightness TFT LCD, 320×240 pixels |

| Storage |

500 data sets, including system setup, detection state, echo figures, etc. |

| Power Supply |

12DC (external power supply); 7.4V (battery) |

| Battery Operating Time |

≥ 8 hrs. |

| Operating Temperature |

-4°-122°F (-20°-50°C) |

| Weight |

Approx. 3 lbs. (1.4 kg) including battery |

| Dimensions |

6" x 9.4" x 2.7" (152 x 240 x 68mm) |