| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| NDT Systems Bondascope 3100 Hand Held Bond Tester | BT-NDT-BOND-3100-PKG |

|

Request Pricing | ||

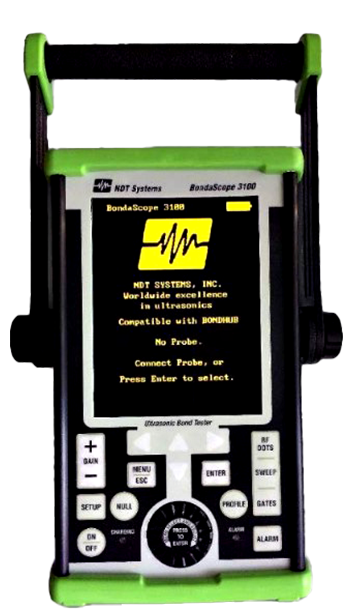

The Bondascope 3100 is a portable ultrasound Bond Tester that uses 3 different testing modes to cover a range of material inspection. Operating typically between 20kHz - 400kHz, the lower frequency enables deeper penetration through materials, across multiple glue lines and even sandwich cores to detect far-side defects. It's testing modes utilize Pitch-catch, Mechanical Impedance Analysis (MIA), and Resonance inspection for test samples. All other manufacturers’ probes may be used in conjunction with the Bondascope 3100. The Bondscope 3100 works with the BondHub II and Scanners to create high-resolution C-Scan images.

The Bondascope 3100 is only one of three components necessary to create C-Scan images. The Bondascope 3100, Bondhub, and Scanner (in this case, the CrosScan Automatic Scanner) work together to create the C-Scan image. The Bondascope 3100 sends live readings from the CrosScan, which traverses the Composite Material, to the Bondhub, where the C-Scan image is created via the CompVu Interface in MIA, Pitch-Catch, or Resonance readings--depending on Probe Type. Probes, scanners, and BondHub must be bought separately. Click here for the Bondascope 3100 purchasing and here for the CrosScan.

As noted above, one of the defining features of the Bondascope 3100 is its universal Probe acceptance and automatic recognition. As a result, Probe selection is extensive. Please consult the following Probe Guide when researching and deciding on your probe needs.

Going hand in hand with Probe Selection, deciding on a Bond Test Mode is of equal importance. Consult the Bond Test Selection Guide to supplement your application research.

When a probe is connected to the Bondascope 3100, the automatic recognition optimizes the settings for the probe type. There are 6 inspection methods available:

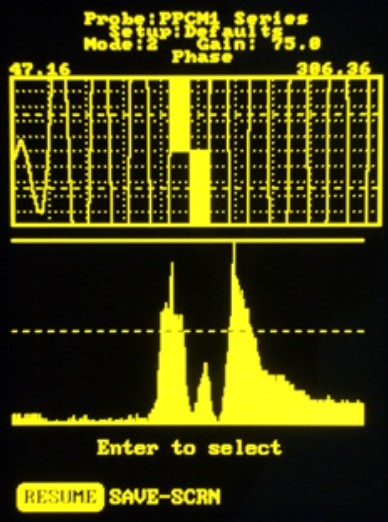

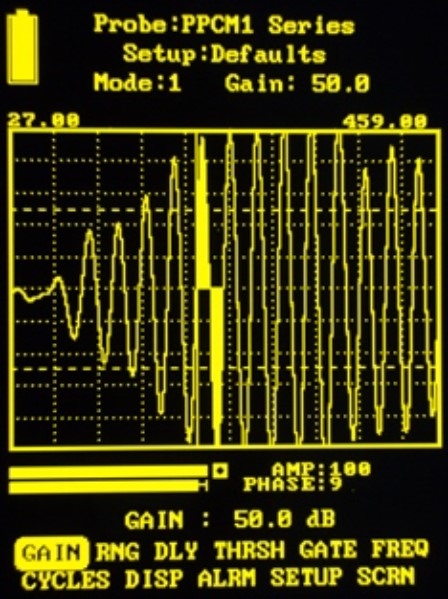

Results can be displayed in different modes including live RF envelope or impedance plane display. A time-encoded profile of phase and amplitude can also be used for rapid scanning. Finally, a C-Scan image will be generated when the BondaScope is used in conjunction with the BondHub II.

There is a range of probes available for each inspection method and the system is compatible with probes from other manufacturers for added functionality.

The Bondascope 3100 excels at composite material testing. Its design allows any probe to be used to measure any test. The field of Bond Testing, and by extension, Material Science, is broad--which is why the Bondascope 3100 is designed to accept virtually any bond testing probe. It is adaptable to any virtually any situation where material integrity is concerned. Let's define some of the areas where the Bondascope 3100 analysis excels:

Finally, if used in conjunction with the BondHub II, 3D or C-Scan imaging can be performed on any of the above listed applications.

| Bondascope 3100 | |||

| Display: | 240 x 320 pixels, quarter-VGA, 5.7"(14.4mm) diagonal EL | ||

| Power source: | Field-replaceable Li-ion battery (autonomy = 8 hours) or AC power | ||

| Operating Temperate: | 32 F - 105 F (0 °C to 40 °C) | ||

| Storage Temperature: | -4 F - 140 F (-20 °C to 60 °C) | ||

| Connector Type: | Standard 11-pin Fischer & 8-pin Lemo (compatible with probes of other manufacturers) | ||

| Connectivity: | Connectivity | ||

| Probe Type Frequency: | Pitch-Catch (tone burst, pulsed & swept frequency) | MIA (fixed & swept frequency) | Resonance 250Hz - 1.5MHz (probe and setup specific) | adjustable frequency, adjustable cycles | ||

| Gate Type Display Modes: | Up to 8 independent rectangular, elliptical or circular shaped gates in impedance plane mode RF, Impedance plane (flying dot, swept mode), Profile mode | ||

| Probe Types: | Pitch-Catch: Spring loaded or fixed tips Tone burst or pulsed and high voltage option Low, medium or high frequency |

Mechanical Impedance: 1/4”, 3/8”, 1/2” tip dia (6.35mm, 9.53mm, 12.70mm) |

Resonance: Standard- 110kHz, 165kHz, 200kHz, 250kHz, 280kHz, 330 kHz, 370 kHz. Honeycomb- 18kHz, 26kHz, 53kHz |

| Dimensions: | 5.75 x 9.5 x 3.0in (14.6 x 24.1 x 7.6cm) | ||

| Weight: | 5lbs (2.27kg) | ||

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| NDT Systems Bondascope 3100 Hand Held Bond Tester | BT-NDT-BOND-3100-PKG |

|

Request Pricing | ||