As a variety of new materials are being introduced to the market, the need for Vickers and Knoop micro hardness testing has greatly increased. The Clark CM Series Micro Hardness Testers utilize advanced technology for incredibly accurate test results. And for optimum flexibility, combine the CM Tester with our available ARS Software for a complete automated testing system.

Features:

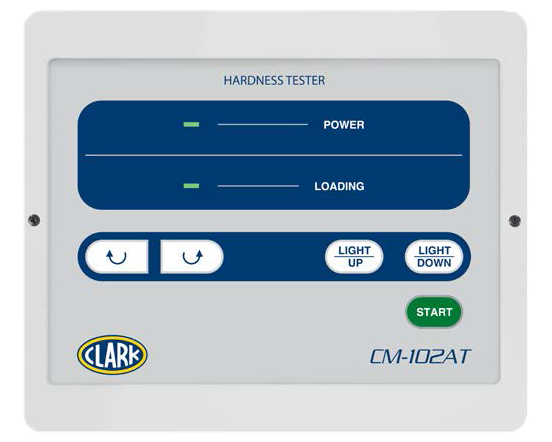

CM-102 / CM-102AT

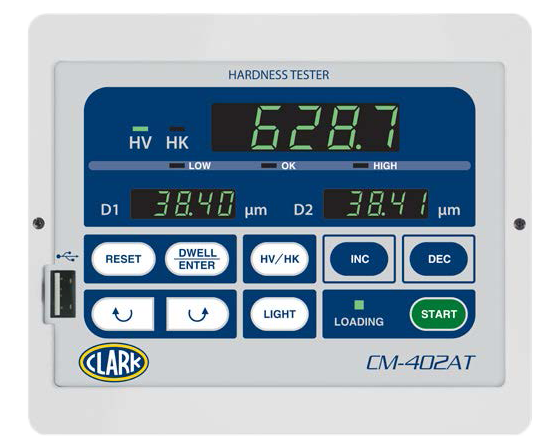

CM-402 / CM-402AT

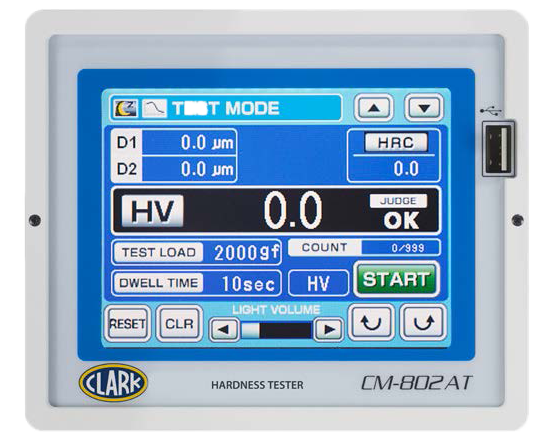

CM-802 / CM-802AT

| Test Load Type A - gf(N) | 10 (98.07), 25 (245.2), 50 (490.3), 100 (980.7), 200 (1961), 300 (2942), 500 (4903), 1000 (9807) |

| Test Load Type B - gf(N) | 5 (49.03), 10 (98.07), 25 (245.2), 50 (490.3), 100 (980.7), 200 (1961), 300 (2942), 500 (4903) |

| Test Load Type C - gf(N) | 50 (490.3), 100 (980.7), 200 (1961), 300 (2942), 500 (4903), 1000 (9807), 2000 (19614) |

| Test Load Type D - gf(N) | 1 (9.807), 5 (49.03), 10 (98.07), 50 (490.3), 100 (980.7), 300 (2942), 500 (4903), 1000 (9807) or 2000 (19614) |

| Test Load Type E - gf(N) | N/A |

| Loading Mechanism | Automatic (loading, holding, removing method) |

| Applying Load Speed | 55μm/sec |

| Dwell Time | 5-40 sec |

| Turret Mechanism | Manual or Automatic Turret (AT) |

| Microscope Magnification | Measurement: 500X (obj. 50X – eyepiece 10X) Observation: 100X (obj. 10X – eyepiece 10X) |

| Measuring Microscope | Mechanical |

| Microscope Max. Measuring Length | For 100X:850μ m / For 500X: 170μ m |

| Microscope Min. Graduation | Micrometer: 0.5 μ m |

| Microscope Min. Measuring Unit | Eye judgement: 0.1μ m |

| Available Test Parameter | HV/HK |

| Fracture Toughness Test | N/A |

| Data Display | Power / Loading |

| Data Output | N/A |

| Hardness Conversion | N/A |

| OK/NG Criteria | N/A |

| Accuracy | Conforms to tolerances per ASTM E-92, ISO 6507-2, ISO 4545-2 |

| Dimensions of X-Y Stage | 3.9" x 3.9" (100 x 100mm) |

| Max. Movement | 25mm in X & Y axis |

| Min. Micro Graduation | 1/100mm |

| Max. Height of Specimen | 3.75" (95mm) |

| Max. Depth of Specimen | 4.5" (115mm) |

| Dimensions | 7.3" x 17.7" x 19.8" / 186 x 450 x 504 mm |

| Weight | Approx. 85 Lbs / 39 kg |

| Power Supply | 120 VAC 1Ø 2A / (AC 100~240V) Please Specify |

| Test Load Type A - gf(N) | 10 (98.07), 25 (245.2), 50 (490.3), 100 (980.7), 200 (1961), 300 (2942), 500 (4903), 1000 (9807) |

| Test Load Type B - gf(N) | 5 (49.03), 10 (98.07), 25 (245.2), 50 (490.3), 100 (980.7), 200 (1961), 300 (2942), 500 (4903) |

| Test Load Type C - gf(N) | 50 (490.3), 100 (980.7), 200 (1961), 300 (2942), 500 (4903), 1000 (9807), 2000 (19614) |

| Test Load Type D - gf(N) | 1 (9.807), 5 (49.03), 10 (98.07), 50 (490.3), 100 (980.7), 300 (2942), 500 (4903), 1000 (9807) or 2000 (19614) |

| Test Load Type E - gf(N) | N/A |

| Loading Mechanism | Automatic (loading, holding, removing method) |

| Applying Load Speed | 55μm/sec |

| Dwell Time | 5-99 sec |

| Turret Mechanism | Manual or Automatic Turret (AT) |

| Microscope Magnification | Measurement: 500X (obj. 50X – eyepiece 10X) Observation: 100X (obj. 10X – eyepiece 10X) |

| Measuring Microscope | Electronic |

| Microscope Max. Measuring Length | For 100X:850μ m / For 500X: 170μ m |

| Microscope Min. Graduation | 0.01μ m |

| Microscope Min. Measuring Unit | Digital: 0.01μ m / In case of 500X |

| Available Test Parameter | HV/HK |

| Fracture Toughness Test | N/A |

| Data Display | D1 / D2 / HV-HK / Hardness Value / Loading / OK-NG Criteria |

| Data Output | D1 / D2 / HV-HK / Test Load / OK-NG |

| Hardness Conversion | N/A |

| OK/NG Criteria | Limit setting and HI / OK / LO display |

| Accuracy | Conforms to tolerances per ASTM E-92, ISO 6507-2, ISO 4545-2 |

| Dimensions of X-Y Stage | 3.9" x 3.9" (100 x 100mm) |

| Max. Movement | 25mm in X & Y axis |

| Min. Micro Graduation | 1/100mm |

| Max. Height of Specimen | 3.75" (95mm) |

| Max. Depth of Specimen | 4.5" (115mm) |

| Dimensions | 7.3" x 17.7" x 19.8" / 186 x 450 x 504 mm |

| Weight | Approx. 85 Lbs / 39 kg |

| Power Supply | 120 VAC 1Ø 2A / (AC 100~240V) Please Specify |

| Test Load Type A - gf(N) | 5 (49.03),10 (98.07), 25 (245.2), 50 (490.3), 100 (980.7), 200 (1961), 300 (2942), 500 (4903), 1000 (9807), 2000 (19614) |

| Test Load Type B - gf(N) | 1 (9.807), 3 (29.42), 5 (49.03), 10 (98.07), 50 (490.3), 100 (980.7), 200 (1961), 300 (2942), 1000 (9807) |

| Test Load Type C - gf(N) | 1 (9.807), 5 (49.03), 10 (98.07), 25 (245.2, 50 (490.3), 100 (980.7), 200 (1961), 300 (2942), 500 (4903), 1000 (9807) |

| Test Load Type D - gf(N) | 1 (9.807), 5 (49.03), 10 (98.07), 25 (245.2), 50 (490.3), 100 (980.7), 300 (2942), 500 (4903), 1000 (9807) or 2000 (19614) |

| Test Load Type E - gf(N) | 1 (9.807), 5 (49.03), 10 (98.07), 25 (245.2), 50 (490.3), 100 (980.7), 300 (2942), 500 (4903), 1000 (9807) |

| Loading Mechanism | Automatic (loading, holding, removing method) |

| Applying Load Speed | 55μm/sec |

| Dwell Time | 5-99 sec |

| Turret Mechanism | Manual or Automatic Turret (AT) |

| Microscope Magnification | Measurement: 500X (obj. 50X – eyepiece 10X) Observation: 100X (obj. 10X – eyepiece 10X) |

| Measuring Microscope | Electronic |

| Microscope Max. Measuring Length | For 100X:850μ m / For 500X: 170μ m |

| Microscope Min. Graduation | 0.01μ m |

| Microscope Min. Measuring Unit | Digital: 0.01μ m / In case of 500X |

| Available Test Parameter | HV / HK / HBW / Kc |

| Fracture Toughness Test | Conforms to JIS R1607 / IF method |

| Data Display | D1 / D2 / HV-HK / Hardness Value / Conversion Data / OK-NG Criteria |

| Data Output | D1 / D2 / HV-HK / Test Load / OK-NG Conv. Scale / Conv. Data / Statistic Data |

| Hardness Conversion | ASTM (E-140) |

| OK/NG Criteria | Limit setting and HI / OK / LO display |

| Accuracy | Conforms to tolerances per ASTM E-92, ISO 6507-2, ISO 4545-2 |

| Dimensions of X-Y Stage | 3.9" x 3.9" (100 x 100mm) |

| Max. Movement | 25mm in X & Y axis |

| Min. Micro Graduation | 1/100mm |

| Max. Height of Specimen | 3.75" (95mm) |

| Max. Depth of Specimen | 4.5" (115mm) |

| Dimensions | 7.3" x 17.7" x 19.8" / 186 x 450 x 504 mm |

| Weight | Approx. 85 Lbs / 39 kg |

| Power Supply | 120 VAC 1Ø 2A / (AC 100~240V) Please Specify |