| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

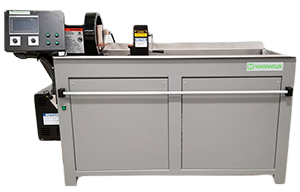

| Magnaflux 1 Phase Wet Bench Testers | MT-MF-PHASE1 |

|

Request Pricing | ||

The Magnaflux A, AD and ADH Series are the most economical Magnaflux brand standard wet bench units. They offer great particle mobility for finding surface and sub-surface defects and the versatility of using AC or DC magnetization (except A-2030). The two outputs are independently adjustable to set each magnetic field, circular or longitudinal.

| Unit | A-2030 | AD-2045 | ADH-2045 |

| Magnetizing Current Capacity: | 3,000 A AC | AC: 4,000 A FWDC: 5,000 A |

AC: 4,000 A HWDC: 5,000 A |

| Maximum Part Length: | 54" (137 cm) (102" (259cm) (146" (370cm) |

54" (137 cm) (102" (259cm) (146" (370cm) |

54" (137 cm) (102" (259cm) (146" (370cm) |

| Maximum Unsupported Part Weight Capacity: Only using Head and tailstock mounted V-Blocks |

300 lbs. (136 kg) | 300 lbs. (136 kg) | 300 lbs. (136 kg) |

| Maximum Supported Part Weight Capacity*: (using rail-mounted steady rests) Both limits are considering the use of Rail Mounted Steady rest to help support parts on rails. |

700 lbs. (317 kg) (1,500 lbs/ (680 kg) |

700 lbs. (317 kg) | 700 lbs. (317 kg) (1,500 lbs. (680 kg) |

| Maximum Part Diameter*: | 12" (30 cm) (16" (40 cm) |

12" (30 cm) (16" (40 cm) (20" (50 cm) |

12" (30 cm) (16" (40 cm) (20" (50 cm) |

| Particle-Bath Tank Capacity*: | 20 gal. (75 L) (32 gal. (121L) (55 gal. (208 L) |

||

| Available Voltage: | 230, 380, 415, 460, 575 V | 230, 380, 415, 460, 575 V | 230, 380, 415, 460, 575 V |

| Available Frequencies: | 50 or 60 Hz | 50 or 60 Hz | 50 or 60 Hz |

* Optional feature configurations shown in italics

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Magnaflux 1 Phase Wet Bench Testers | MT-MF-PHASE1 |

|

Request Pricing | ||