Foundrax Brintronic Series automatic Brinell microscopes

The Foundrax BRINtronic system offers unrivalled performance for the automatic optical measurement and recording of Brinell indentation diameters. Available in a variety of stand-alone formats or as a fully integrated system in a range of Foundrax machines, it provides a robust and accurate solution to the challenges of Brinell hardness testing .

The BRINtronic system comprises an automatic Brinell microscope system linked to specially developed software that allows the system to accurately and reliably measure indentations, record the results and create a valuable log of test information.

The Brinell microscope is able to optically measure indentation diameters in industrial conditions, with a minimum of surface preparation on the test area, and across a range of materials. It does this in only a few tenths of a second, so the test cycle time is minimised so that productivity is maximised.

The whole testing and recording process is automated so once the test is initiated by the operator, there are no external influences that might compromise the integrity and accuracy of the results.

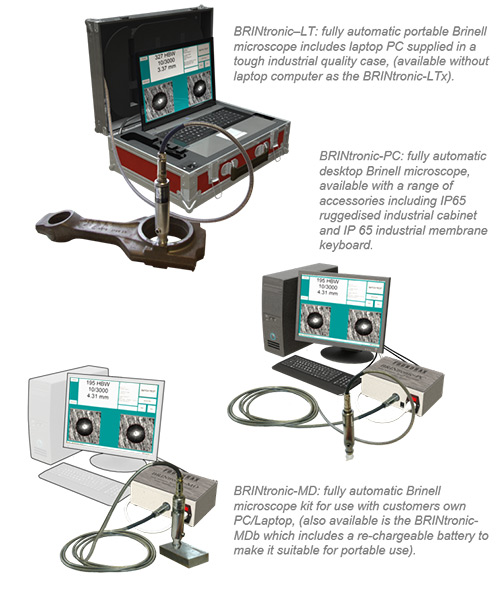

Stand-alone systems

The following three models are available as separate units:

|

The BRINtronic-LT in use on the shop floor |

Ergonomically designed stainless steel microscope is compact, robust and easy to use |

Test surface preparation in seconds using simple hand grinder |

BRINtronic automatic Brinell microscope system – the focus on detail

The BRINtronic system provides a complete solution for the measurement and recording of test results and has a number of features that enhance functionality. It can:

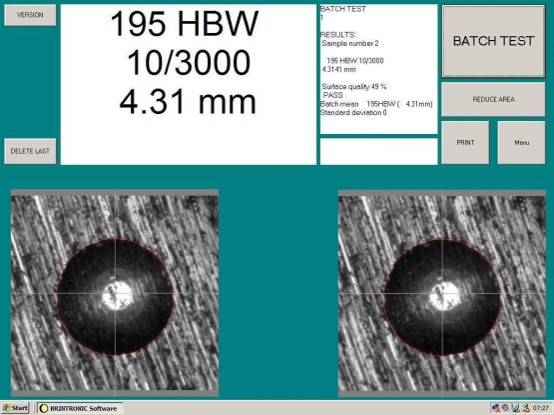

Main test screen showing live and measured images, test results, surface quality and batch statistics

The on-screen menu is both intuitive and easy to use, allowing both batch and single testing if desired. The batch set-up screen is customizable to allow for extra fields such as multiple indentations per component, operator name, customer etc. to allow for greater detail in record keeping. Test reports are available in three formats:

In addition the system is fully networkable and can communicate with a remote computer and download/upload batch data if required.

The BRINtronic system leads the industry for reliability and repeatability.

The software is written and developed by Foundrax; therefore special requirements can be easily accommodated

|

Specifications:

|

Available Hardness scales Either one or two of the following:

|

The BRINtronic series fully complies with ISO 6506 and ASTM E10