| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| VisiConsult InSpect Small Footprint X-ray Inspection Device | RT-VC-INSPECT |

|

Request Pricing | ||

VisiConsult InSpect

Small Footprint X-ray Inspection Device

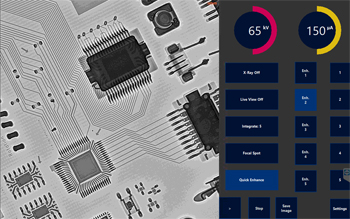

The VisiConsult InSpect is a compact X-ray inspection cabinet for all types of applications. It is perfectly suitable for laboratories, dentists, forensic institutes and educational bodies, but can also be used in an industrial environment to inspect electronics, castings or other parts. The system is available with various hardware configurations depending on the inspection task. In order to ensure an easy inspection, the system can be operated as a stand-alone device through the high-resolution touch panel and simplified Xplus software.

| The InSpect cabinet is equipped with a high-resolution touch panel for fast and intuitive operation. Main functions of the system, like energy, current and exposure time can be set within seconds. Commonly used parameters can be easily stored. In case the real-time module with a digital radiography detector (DDA) is installed, the user can directly display an image preview on the panel and perform basic image enhancements. |

Modular Design and High Quality

| To provide the best inspection results, VisiConsult supplies a broad variety of X-ray components. The tube and detector can be freely combined depending on customer preferences or application requirements. For maximum safety the cabinet is certified by the German TUV and CE to ensure no X-ray leakage and the fulfillment of all related standards. The robust industrial design, developed and produced in Germany, guarantees a long life and low downtimes, even under demanding conditions. The inspection results can be reviewed at the system, in an operator cabinet or through offline stations. |  |

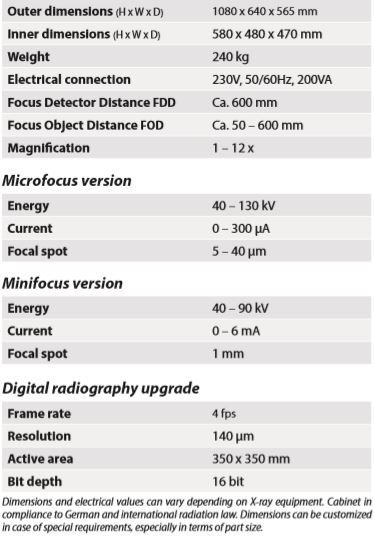

| Depending on the application and inspected specimens, the InSpect cabinet can be equipped with a Microfocus or Minifocus tube. The Microfocus tube allows high magnification of even delicate structures like electronic components or organic materials. The Microfocus tube has more power to penetrate materials with higher densities like aluminum castings or other metal objects. |

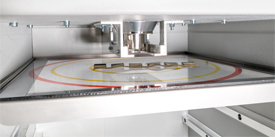

| If the cabinet needs to be integrated into a production line, VisiConsult offers an automation upgrade. This allows conveyor belts to run through the cabinet body to perform automated (ADR) in-line inspection. Such solutions are always customized towards the specific application. |  |

Xplus Software

The core of the system is the in-built image enhancement system Xplus. Advanced features like overlay tools, macro generators, filter builders, live image enhancement, report toolkits, DICONDE integration, measurement tools and many more features make the Xplus the most sophisticated software on the market, leading to brilliant image quality. Automated inspection sequences lead to unmatched efficiency and process safety. VisiConsult's constant development and 25 years of experience combined with maximum flexibility towards special process requirements, help our customers be one step ahead of the competition.

To allow simple and fast operation, the InSpect runs a light Xplus version for image acquisition, processing, archiving and simple inspection. It is fully touch operated and very intuitive. More complex operations can be performed on an offline review station.

Technical Specifications:

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| VisiConsult InSpect Small Footprint X-ray Inspection Device | RT-VC-INSPECT |

|

Request Pricing | ||