| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt SNK B-35 (L) Automated Ultrasonic and Eddy Current Testing System for Mill Rolls | UT-OKO-SNKB35L |

|

Request Pricing | ||

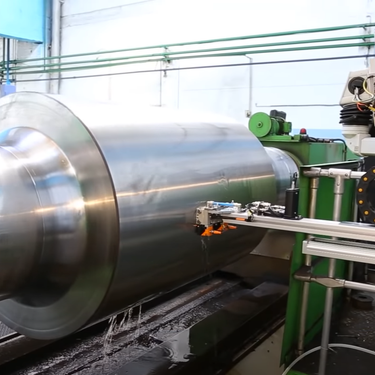

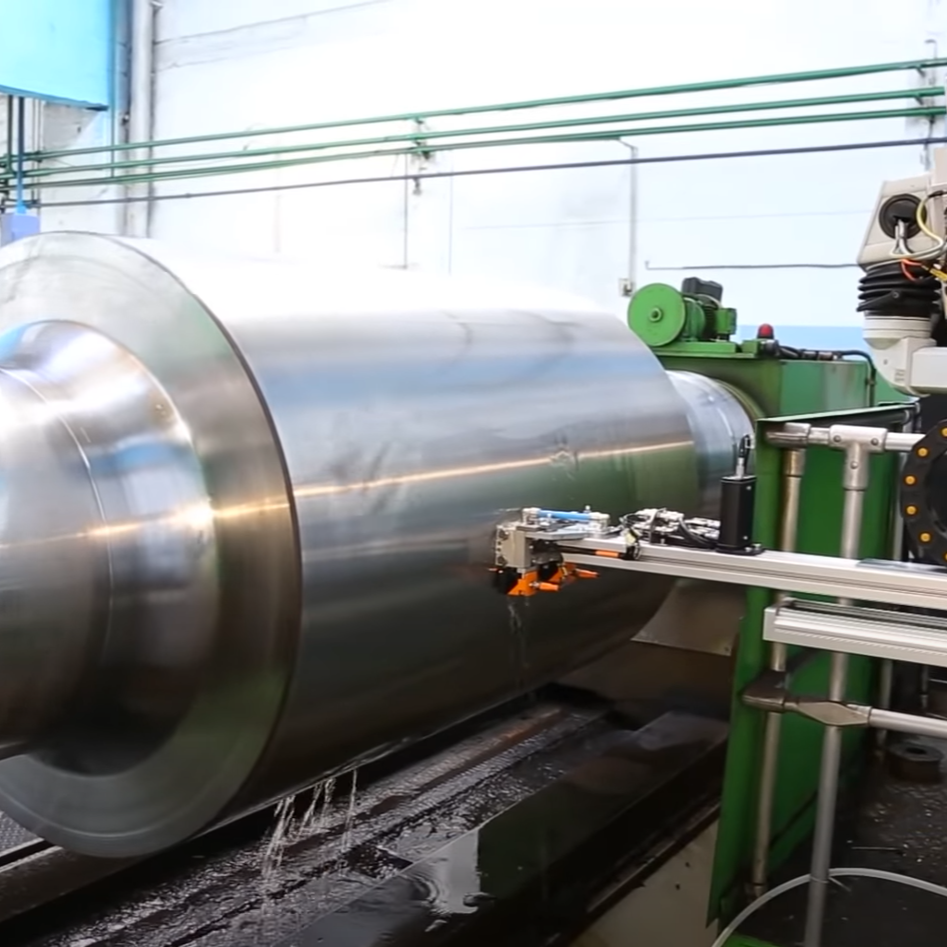

The SNK B-35 (L) is designed to automatically detect inadmissible internal and external defects of a roll body. Detects defects in the roll body metal such as: reed marks, flux inclusions, cracks, folds, cleavages, etc. The SNK B-35 (L) can be integrated to support all roll-grinding machine systems, regardless of the type or manufacturer. Features an online display of the position of the scanner using the coordinate system of the grinding machine.

Calibration Mode

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt SNK B-35 (L) Automated Ultrasonic and Eddy Current Testing System for Mill Rolls | UT-OKO-SNKB35L |

|

Request Pricing | ||