RH-150 Rockwell Hardness Tester

This model has been discontinued and replaced with the RH-150Auto Rockwell Hardness Tester!

FEATURES:

- High accuracy, repeatability and reliability

- Easy to use anywhere

- Suitable to test metal parts of any size and shape

EASY TO USE

Place the test piece between the adjust supporter and indenter

Press a 10 Kg preliminary load

Press the main load

Unload 10Kg

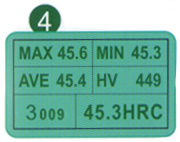

Display the Readings

Suitable to test metal parts of any size and shape

|

|

|

|

|

Testing a spring

|

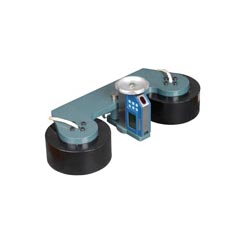

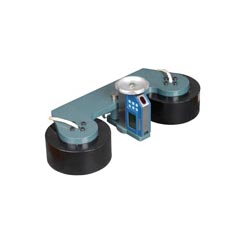

Testing a larger part by a magnetic clamp

|

Testing on a platform

|

|

|

|

|

|

Testing on a Lathe

|

Testing on a milling machine

|

Testing in a ring

|

Rockwell Hardness Testing and the ASTM E 18-03 Standard

Rockwell Hardness testing is a system for determining hardness of metallic material. The E 18-03 standard established by ASTM is a detailed description of the Rockwell Hardness testing method.

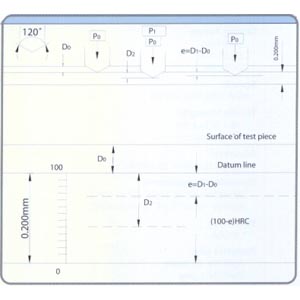

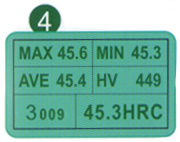

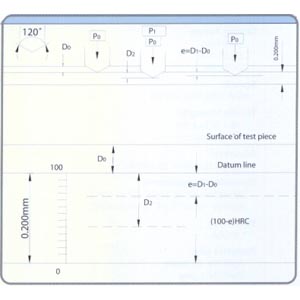

A 120 degree angle diamond or 1/16” (1.588mm) diameter hard steel ball indenter, is pressed into the test piece surface with a preliminary force Po (10kgf) at a depth Do. Then, a main force P1 is added until the total test force, P = Po + P1 is 60kgf for HRA, 100kgf for HRB and 150kgf for HRC and the indenter increases to a depth D2. Then, the preliminary force Po is unloaded and the indenter decreases to a depth D1. This results in a depth difference, e = D1 – Do, are measured in units of 0.002mm. The hardness reading for HRA and HRC is 100-e, and for HRB is 130-e