Residual magnetism is the enemy of the modern industrial manufacturing process. It makes it impossible for parts to become sufficiently clean after being washed, and prevents welding processes from running smoothly. The Maurer VE + DN has been specifically designed to eliminate residual magnetism and fit right in with the rest of your automated process line.

Depending on the design, the VE + DN creates a degaussing field of roughly 628 - 4,521 Gauss (or 50 - 360 kA/m), making it possible to demagnetize bulk parts in carriers, transport containers, or complex individual parts. Using the pulse demagnetization method, and with a pulse lasting only a few seconds, the VE + DN achieves superior results on a level never before reached.

What VE + DN Means for You:

Integration into Production Lines

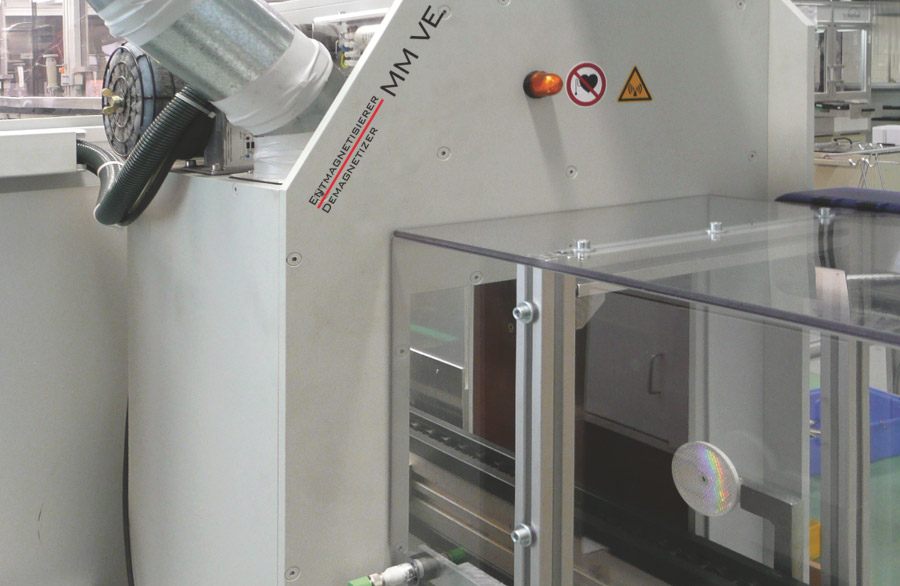

The VE + DN is typically deployed in automated industrial manufacturing, where productivity and process security are decisive factors. The simple and intuitive functionality of the VE + DN Demagnetizer makes it easily fit into every manufacturing process.

Optimally-Tailored Demagnetization Solution

The parameters of the demagnetization process are predetermined by tests and experience gained from similar applications. The demagnetization solution is implemented quickly using optimally designed power and coil modules.