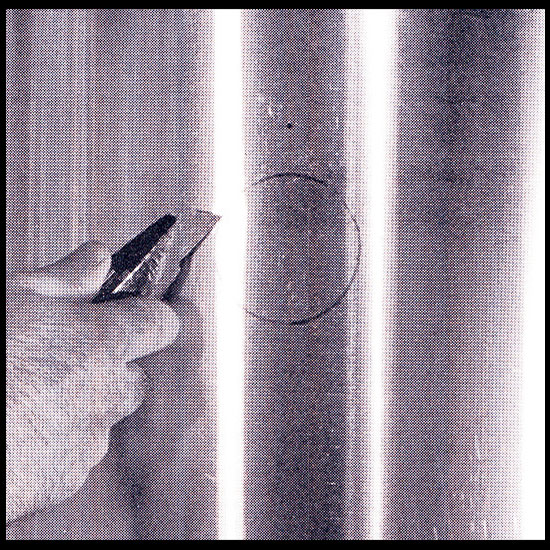

Step 4

Using the correct tool for your specific insulation material, remove the insulation as required to expose the pipe/vessel surface.

Step 4.1: Perform the following options prior to next step if applicable:

- Field Contour the flange for small diameter piping if needed

- Install the Separation Sleeve at this step if needed

- Install the Transition Gasket if needed

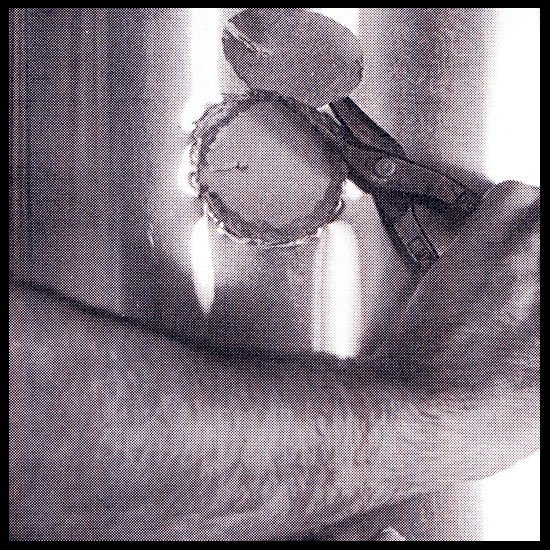

Step 5

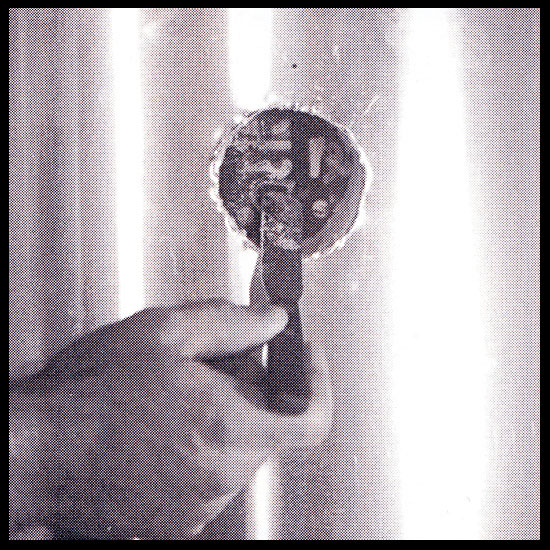

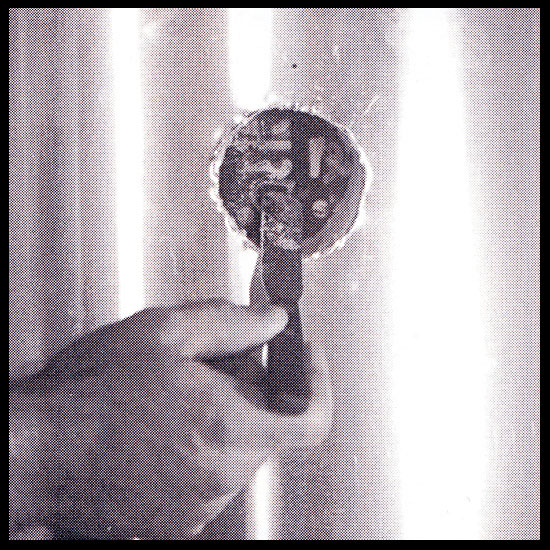

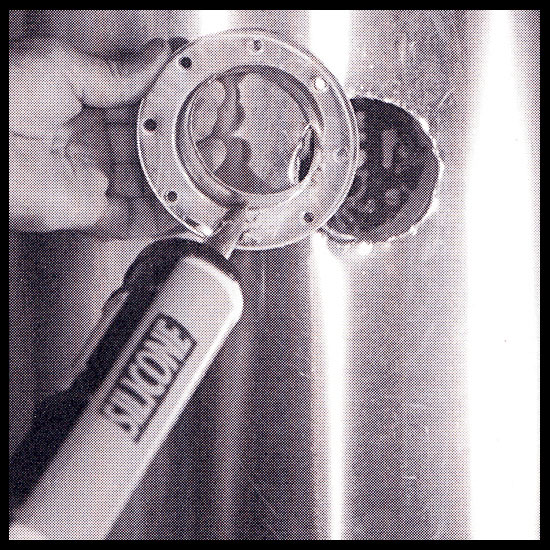

Fill the backside of flange with a high grade silicone adhesive and insert the flange into the cut hole to shield the cut edge

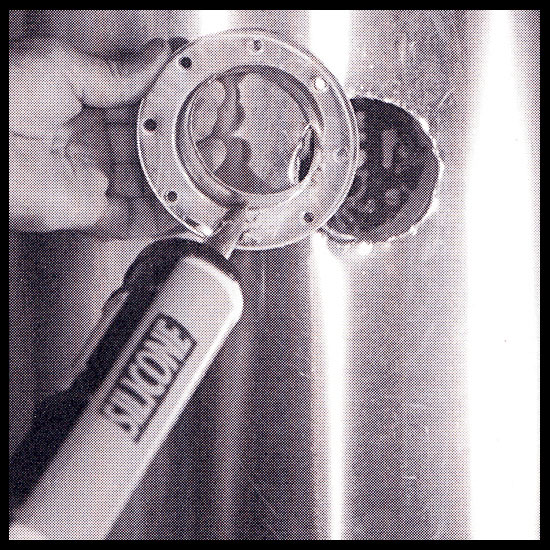

Use the silicone injection holes along the face of the flange to fill any voids and to make sure you have an airtight seal between the flange and the jacketing

Step 6

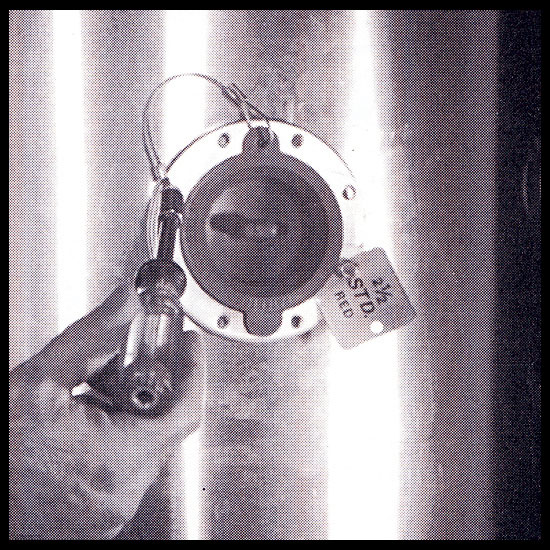

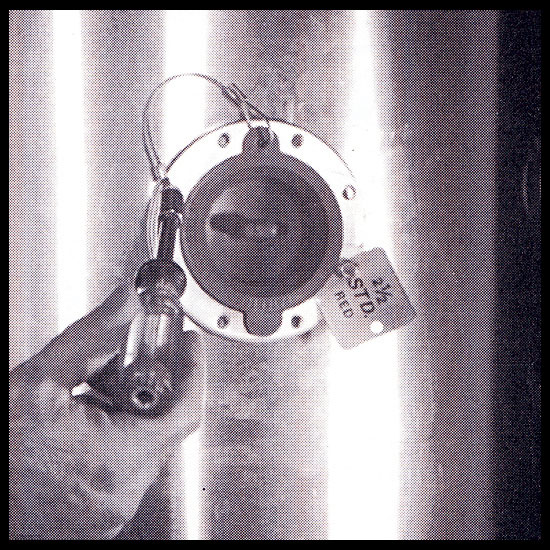

Install two (2) #10 self-tapping stainless steel screws across from each other to hold the flange in place while the silicone cures. Make sure one of the screws is used to attach the safety line to the flange.

**NOTE: Installers may want to use aluminum or stainless steel pop rivets in lieu of self-tapping screws as an alternate fastening method. Insert an insulation core into the inspection hole and secure the stopper in the flange. If you are installing our high temperature, all metal, inspection ports; make sure the cup in fully engaged with the locking tabs to create the seal.