Key Benefits

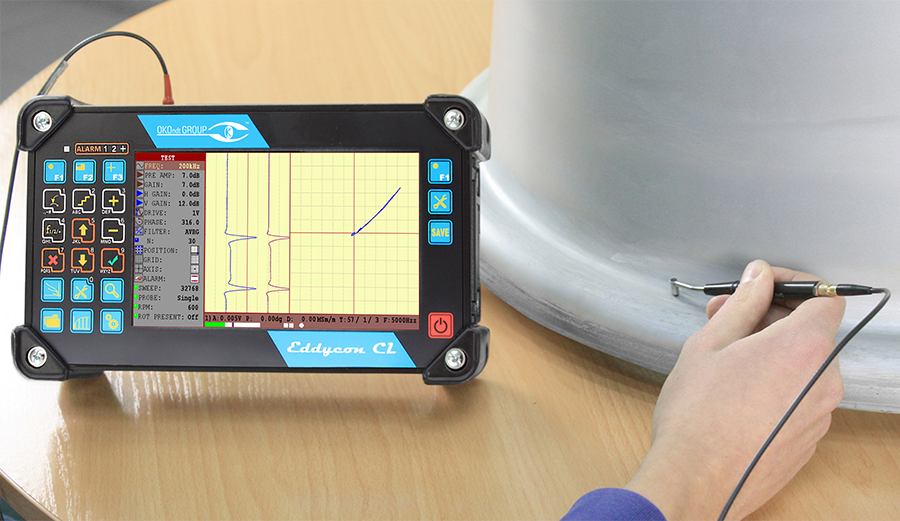

HD Display

7.2" TFT color display with 800×480 pixels resolution ensures a large, high-definition picture on the screen. The screen has several display modes, such as light, dark, and standard.

Intuitive Software

The specialized application-dependent software of the Eddycon CL is user-friendly and intuitive, serving to process, generate and print out test results and reports. The software program allows working with the data saved on PC.

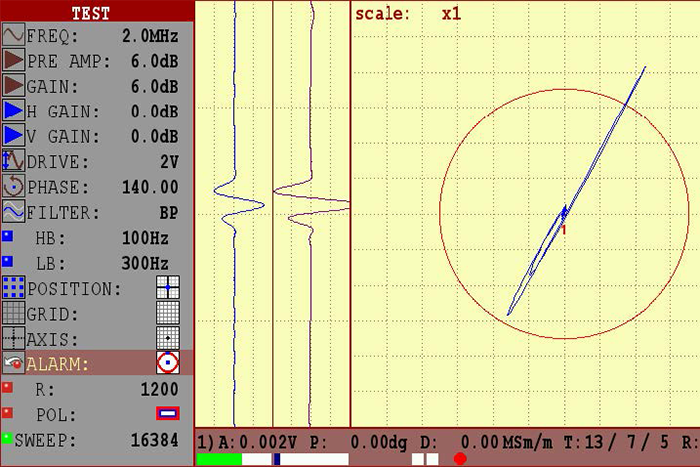

Quick Navigation

The keypad design gives a quick access to any menu of the flaw detector by pressing only a single key

- TESTING menu - main operating mode of the flaw detector

- MEMORY menu - is used to save/download the settings and test results

- SETTINGS menu - basic settings of the flaw detector

- VIEW menu - allows viewing test results saved to the flaw detector’s memory

- CALIBRATION menu - serves to create calibration curves for more precise evaluation of flaw depth