| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| ECUTEC Tube Calibration Standards | EC-ET-TUBECAL |

|

Request Pricing | ||

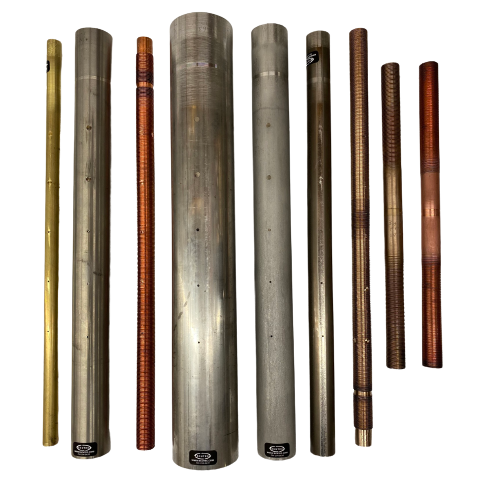

ECUTEC offers many different standards including ASME, RFT, NFT, ECA, NFA, IRIS, PSEC/FSEC, or any custom standard that you may require. Options include flat bottom holes(FBH), side drilled holes (SDH), round bottom pits, ID or OD grooves (90°, 180°, 270° & 360°), taper cuts, EDM notches, spiral grooves, expansions & more designed to your needs and tolerances. Calibration standards may be fabricated with a milling machine, lathe, electrical discharge machine (EDM), and/or surface grinder.

ECUTEC carries stock of many different materials in most standard sizes in prime or finned OD and ID configurations. Options include stainless steel (300 & 400 series, 2205/2507 Duplex, AL6XN, SEA-CURE, etc.), titanium, copper, Monel, copper nickel (90/10 & 70/30), brass, Admiralty brass, aluminum, alloy 20, chrome moly, Hastelloy, Inconel/Incoloy, nickel, tantalum, zirconium, aluminum brass & others.

Current inventory comprises of tube/pipe sizes from 0.1/4” OD up to 24” OD, as well as some metric sizes. ECUTEC stocks raw material, as well as stock ready-made standards of the most popular varieties. This includes ASME for non-ferrous materials, RFT for ferrous materials, and ECUTEC standards for chiller tube materials.

ASME Calibration Standards

(Fits nine <3/4” and three <1.5” tubes)

ECUTEC Spec Standard Case

ECUTEC Spec Double Stack Standard Case

(Fits up to 44 Standards)

Single pipe standards require diameter, wall thickness and material.

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| ECUTEC Tube Calibration Standards | EC-ET-TUBECAL |

|

Request Pricing | ||