| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt TOFD 2.2 PRO Wireless Ultrasonic Testing System | UT-OKO-TOFD-2.2-PRO |

|

Request Pricing | ||

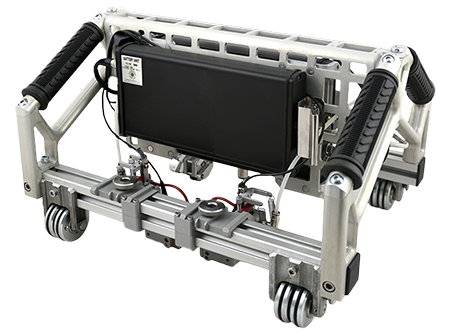

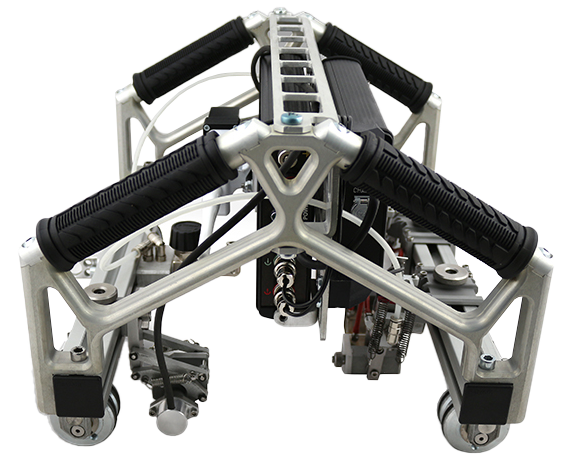

OKOndt's TOFD 2.2 PRO System performs mechanized ultrasonic testing of butt welds using Time-Of-Flight Diffraction (TOFD) technique. The TOFD method has been widely used for fast and reliable ultrasonic testing of welded joints and offers great accuracy for measuring the critical size of crack-like-defects. An accuracy of better than ±1mm (0.03") can be achieved in a wide range of material thicknesses. The system is shockproof and has an IP65 protecting rating.

Applications include ultrasonic testing of welded joints in:

TOFD Main Advantages

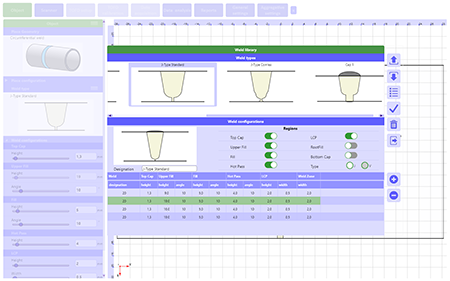

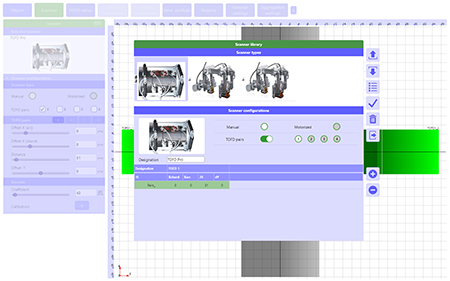

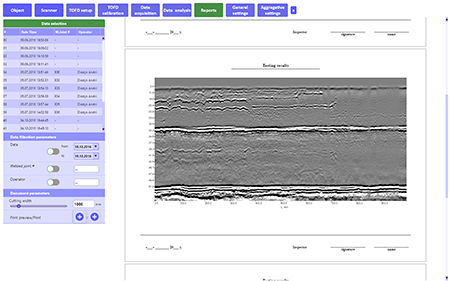

TOFD System Software consists of several tabs that allow NDT inspectors to perform a step-by-step setup procedure, data acquisition and analysis. Easy to use with a mouse or via touchscreen. Quick and comprehensive setup due to the element libraries: Geometry library, Materials library, Scanners library, Probes library, etc. Full setup packages applicable for specific tasks of testing can be saved and loaded when it is necessary at all times.

Main software functions are distributed among the following tabs:

Object Tab

Scanner Tab

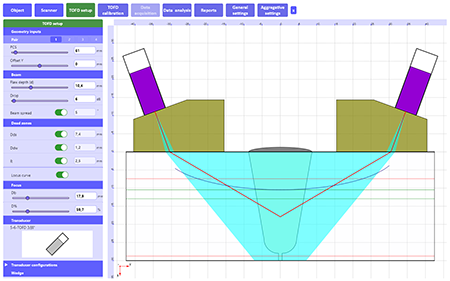

TOFD Setup Tab

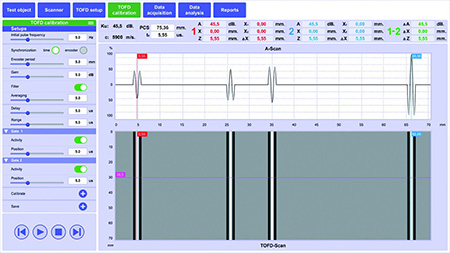

TOFD Calibration Tab

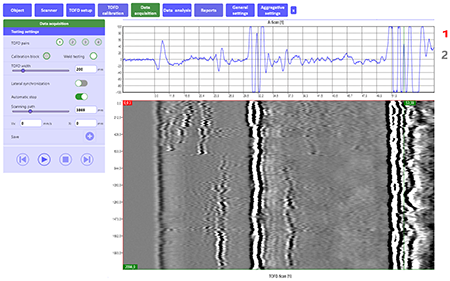

Data Acquisition Tab

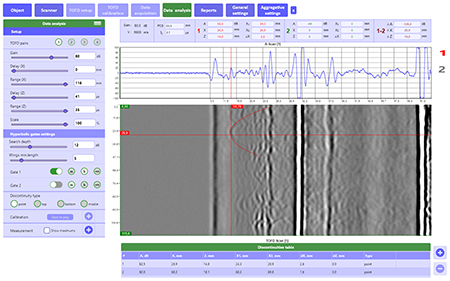

Data Analysis Tab

Reports Tab

General Specifications

| Testing Objects Parameters | |

| Thicknesses | .25" - 2" (6 - 50 mm) |

| Diameter for Cylindrical Objects | from 12" (300 mm) to flat |

| Diameter for Spherical Objects | from 33 ft (10 m) to flat |

| Profile Types | any |

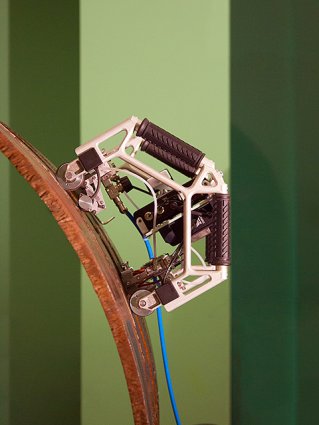

| Scanner (with all electronics onboard) | |

| Dimensions (LxWxH) | 14.9" x 12.2" x 9.4" (380×310×240 mm) |

| Weight | 16.5 lbs. (7.5 kg) |

| Number of TOFD Pairs | 1 |

| Coupling Liquid Supply | Individually for each probe |

| Compatible Probes and Wedges | |

| Frequencies | 1-15 MHz |

| Angles (L-Wave) | 45°, 60°, 70° |

| Measurement | |

| Number of Cursors | 2 |

| Types of Cursors | Conventional (cross) Hyperbolic |

| Manual Positioning | ✔ |

| Automatic Positioning | ✔ |

| Absolute Measurements | ✔ |

| Relative Measurements | ✔ |

| Indications Table | ✔ |

| Indications Parameters | X, X1, X2, dX Z, Z1, Z2, dZ Type (Point, Top, Bottom, Middle, Volumetric) Amplitude |

| Units | mm / in / us |

| Output Fields | 5 |

TOFD Unit Specifications

| Unit Connectors | |

| Pulser and Receiver | 2 × BNC |

| Encoder | ✔ |

| Power | ✔ |

| RS485 | ✔ |

| LAN | ✔ |

| Sync Input | ✔ |

| Trigger Output | ✔ |

| Pulser | |

| Types | SWP |

| Voltage (SWP) | 20 V, 30 V, 40 V, 50 V, 80 V, 100 V |

| Energy (SWP) | 20 ns to 500 ns with 10 ns step Manual & Auto modes |

| PRF | from 15 to 2000 Hz |

| Receiver | |

| Range | Up to 100 us |

| Delay | Up to 100 us |

| Gain | 0 to 110 dB, with 0.1 dB step |

| Max Signal Input | 20 V p-p |

| Bandwidth | 0.2 MHz - 27 MHz |

| Filters | 1 MHz, 2-3 MHz, 4-5 MHz, 10 MHz, 15 MHz, Full band |

| Rectification | RF |

| Signal Average | 2x / 4x / 8x / 16x / 32x |

* = included in basic delivery set

| Catalog Number | Frequency, MHz | Element Diameter | Object Thickness | ||

| in | mm | in | mm | ||

| TWS10-3-TOFD 3/8" | 10 | .125 | 3 | .390 - .600 | 10 - 15 |

| TWS10-6-TOFD 3/8" | 10 | .250 | 6 | .600 - 1.4 | 15 - 35 |

| *TWS5-6-TOFD 3/8" | 5 | .250 | 6 | 1.4 - 2 | 15 - 50 |

| TWS5-12-TOFD M16 | 5 | .500 | 12 | 2 - 4 | 50 - 100 |

| TWS3-12-TOFD M16 | 3 | .500 | 12 | 4 - 8 | 100 - 200 |

| TWS2.5-12-TOFD M16 | 2.5 | .500 | 12 | 8 - 6 | 200 - 300 |

| TWS2.25-12-TOFD M16 | 2.25 | .500 | 12 | 8 - 6 | 200 - 300 |

| TWS3-8-TOFD M16 | 3 | .325 | 8 | 4 - 8 | 100 - 200 |

| TWS2.5-8-TOFD M16 | 2.5 | .325 | 8 | 4 - 8 | 100 - 200 |

| TWS2.25-8-TOFD M16 | 2.25 | .325 | 8 | 4 - 8 | 100 - 200 |

* = included in basic delivery set

| Catalog Number | Thread Diameter | Refracted Angle |

| WS45 L-3/8"-TOFD | 3/8" | 45° |

| WS60 L-3/8"-TOFD | 3/8" | 60° |

| *WS70 L-3/8"-TOFD | 3/8" | 70° |

| WS45 L-M16-TOFD | M16 | 45° |

| WS60 L-M16-TOFD | M16 | 60° |

| WS70 L-M16-TOFD | M16 | 70° |

Additional Options

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt TOFD 2.2 PRO Wireless Ultrasonic Testing System | UT-OKO-TOFD-2.2-PRO |

|

Request Pricing | ||