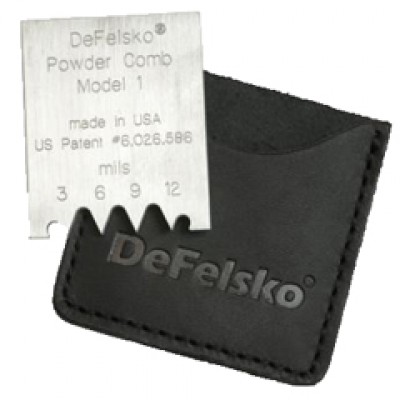

DeFelsko Powder Comb

Check Powder Thickness with Powder Comb before curing to help ensure correctly cured film thickness the first time through. Avoid stripping and re-coating which can cause problems with adhesion and coating integrity.

Versatility

| | - Ideal for set-up and quality control

- Works on a variety of part sizes, shapes and substrates such as metal, plastic, wood, glass and more

- Easy to carry; convenient shirt pocketsize

- Available in microns (metric) and mils (imperial)

|

Quality

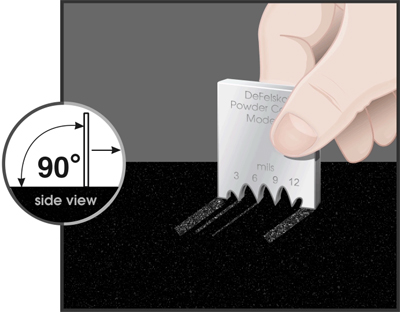

| | - Broad stand-offs on both sides of teeth help keep gauge perpendicular to surface when measuring

- Rugged aluminum construction for long gauge life and static control

- Precision gauge; manufactured to a tolerance of ± 5 microns or ± 0.0002 inch

- Protective leather pouch included with each gauge

|

Simple Operation

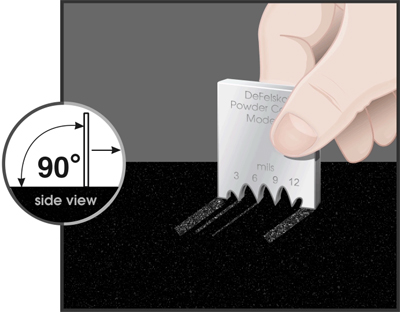

- Push the Powder Comb perpendicularly into the dry powder so that the stand-offs (end tabs) on both side if the teeth rest firmly on the substrate.

- Drag the Powder Comb along the surface of the coated part for at least 1 cm.

- Remove the Powder Comb from the surface and examine the marks left in the powder. The powder thickness is between the highest numbered tooth which made a mark and has powder clinging to it, and the next highest tooth which left no mark and has no powder clinging to it.

|  |

Example: The 3 & 6 mil teeth both make lines and have powder clinging to them, but the 9 mil tooth does not. The uncured powder thickness is determined to be between 6 & 9 mils. (Table below illustrates further).

| Powder Comb Models | Height

Tooth 1 | Height

Tooth 2 | Height

Tooth 3 | Height

Tooth 4 |

| Model 1 (mils) | 3 | 6 | 9 | 12 |

| Model 2 (mils) | 10 | 15 | 20 | 25 |

| Model 3 (mils) | 20 | 30 | 40 | 50 |

| Model 4 (µm) | 75 | 150 | 225 | 300 |

| Model 5 (µm) | 250 | 375 | 500 | 625 |

| Model 6 (µm) | 500 | 750 | 1000 | 1250 |

Note: Most powders cure to approximately 50% of their dry thickness. Marks left by the gauge may affect the characteristics of the cured film.