![]()

1. Couplant 3. Testing Material

![]()

1. Couplant 2. Coating 3. Test Material

The following gauges have both Pulse-Echo (P-E) and Echo-Echo (E-E) Modes.

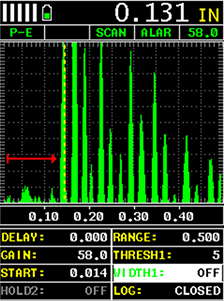

Pulse-Echo (P-E) Mode measures from the surface to the back-wall echo. It is used on bare material to determine wall loss on corroded, eroded and pitted materials. When measuring through a coating the measurement will include an error due to the coating thickness x 2-3 because of the difference in sound velocity between the coating and test material.

A-Scan showing P-E measurement

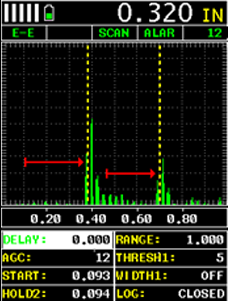

Echo-Echo (E-E) Mode measures from the back-wall echo to its multiple-echo and eliminates the error due to the coating. Measurements can only be made on materials that have parallel surfaces as the multiple-echo will disappear if the back-wall is corroded or pitted.

A-Scan showing E-E measurement