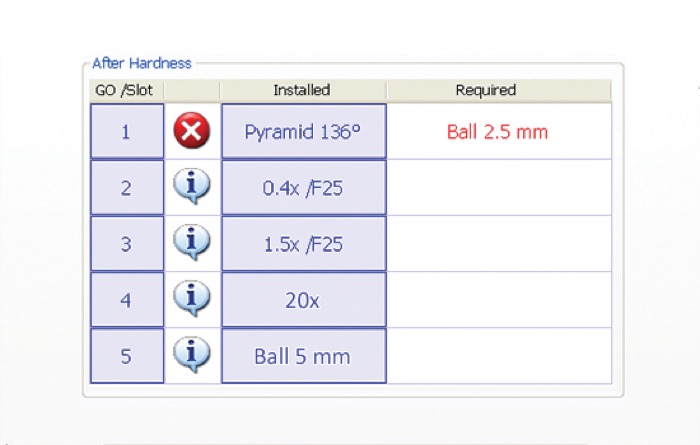

The Affri Integral 1 is an automatic digital hardness tester for the Brinell testing method in compliance with ASTM E10 and ISO 6506 standards, and a top level bench hardness tester for fully automatic Brinell test cycles. It is entirely motorized with an automatic turret with indenter and magnification lenses for Brinell indent auto-reading after indentation. Integral 1 also has a large fixed base and a motorized head with long vertical stroke.

How it Works:

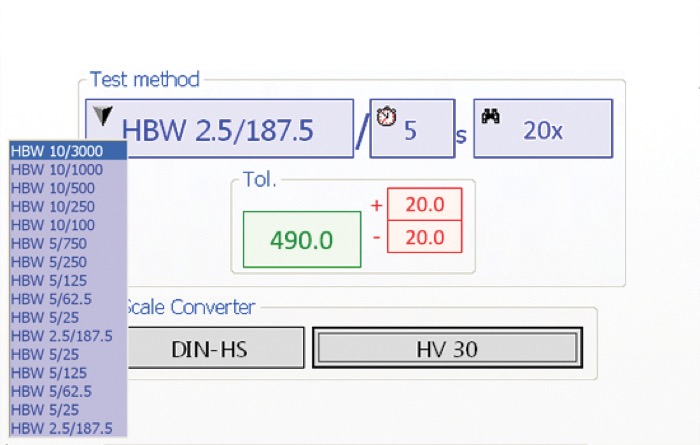

Load forces are applied through load cells and electronically controlled in Closed Loop (Pat. Affri). It successfully performs hardness tests on all metals, including iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys. Accuracy is better than 0.5% in all conditions - the first time, every time - eliminating the need for repeated tests.

One Input for the Entire Test Cycle

The hardness tester’s head moves down until contact is made, clamps the piece, applies the force and makes the indentation. The software will move to the camera view mode where the indentation is automatically measured.

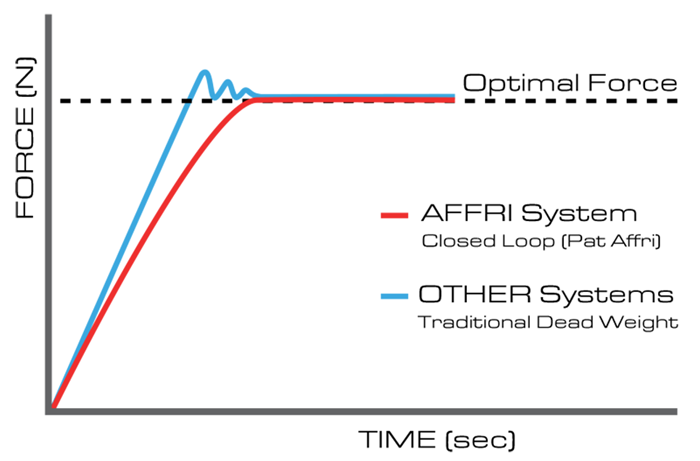

Closed Loop (Pat. Affri)

Closed loop load cells control load forces with a frequency of 1 khz, assuring perfect linearity in every range. Results are not affected by any structural deflection, misalignment or vibration.

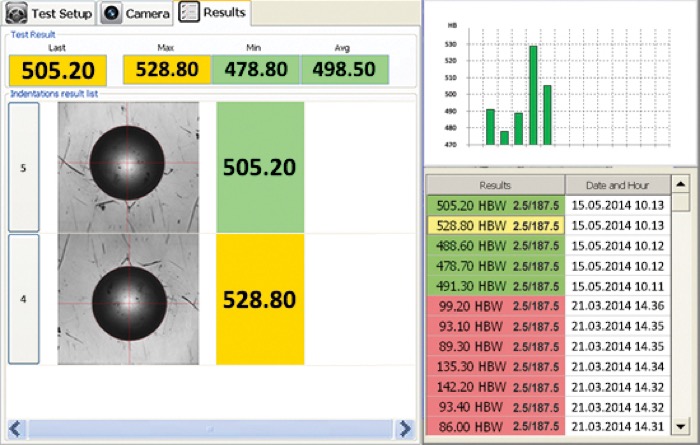

Repeatability and Reproducibility (R&R)

Accurate measurements on the first test, even in extreme conditions, eliminates the need for repeated tests. The R&R data is at the top of its class.

Clamping System (Pat. Affri)

Secure contact with the specimen is always maintained, even in the unlikely event of any specimen movement during the operation cycle. The clamping system assures complete stability of any test piece throughout the test cycle, even if it's oiled, rusty or dirty.

Motorized Head

Automatic movements with automatic stop when contact is made. Total of 500 mm of motorized vertical stroke. The approach of the head moving to the piece as opposed to the piece moving to the head allows for more accurate, stable and safe measurements.

Motorized XY Table

For automatic multi-indentation measurement. The user can program and set the number of indentations to be performed and the related movement of the X/Y table before each indent.

Additional Features:

For more information on purchasing the Affri Integral 1 Automatic Brinell Hardness Tester, please contact us here: