![]()

1. Couplant 3. Testing Material

![]()

1. Couplant 2. Coating 3. Test Material

![]()

1. Couplant 2. Coating 3. Testing Material

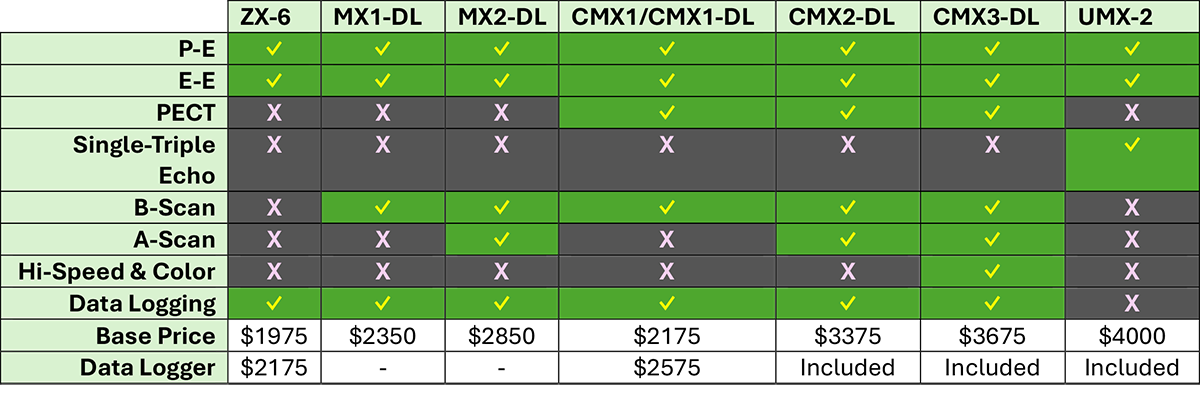

All 3 measuring modes featured in all CMX instruments

Dakota CMX instruments have both basic modes - Pulse-Echo (P-E, 0-1st echo) and Echo-Echo (E-E, Thru-Coating), as well as PECT mode and other additional modes depending on the specific gauge. Includes 2 Year Limited Warranty.

Displays:

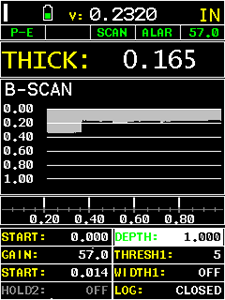

B-Scan

Large Digits

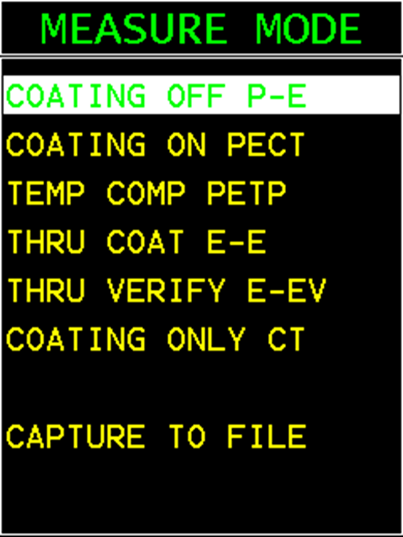

Measuring Modes:

Pulse-Echo (P-E) mode

Echo-Echo (E-E) mode

Echo-Echo-Verify (E-EV) mode

Pulse-Echo-Coating (PECT) mode

Pulse-Echo Temperature Compensated (PETP) Mode

Coating Only (CT) mode

Options:

Data Logger (DL)

Displays:

A-Scan or High Speed Color A-Scan

B-Scan

Large Digits

Measuring Modes:

Pulse-Echo (P-E) mode

Echo-Echo (E-E) mode

Echo-Echo-Verify (E-EV) mode

Pulse-Echo-Coating (PECT) mode

Pulse-Echo Temperature Compensated (PETP) Mode

Coating Only (CT) mode

Features:

Data Logger (DL)

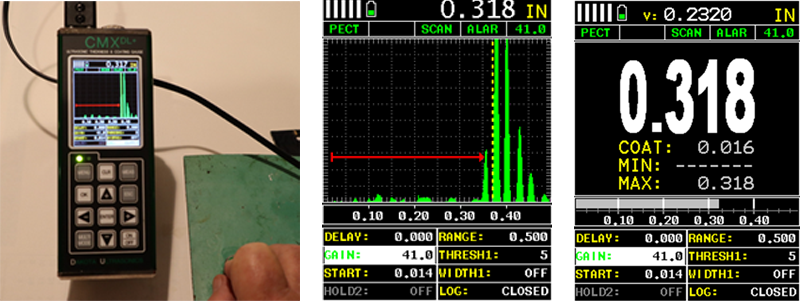

Measures Thru-Coating, detects pitting and measures when Echo-Echo (E-E) mode fails. PECT is a unique method that provides the benefits of Pulse-Echo (P-E) and Echo-Echo (E-). Measure coated material without errors caused by the coating while being able to measure on materials with corroded and pitted back-walls.

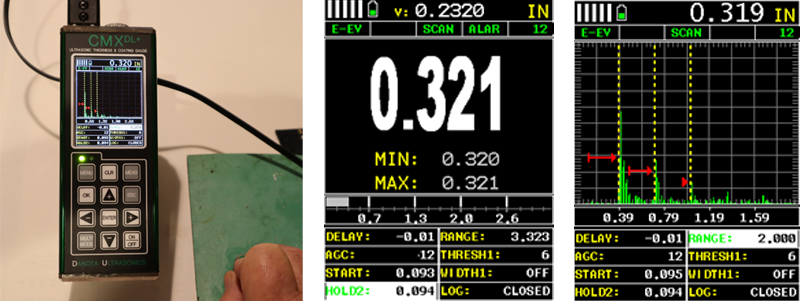

The Echo-Echo-Verify (E-EV) mode measures between 3 reflections. Similar to Echo-Echo (E-E) mode, this technique is commonly used to eliminate errors from surfaces with multiple-layers of coatings. The primary benefit of this mode is that it compares the 2nd and 3rd echoes to verify that a peak jump has not occurred in order to provide an additional level of confidence in the measurement.

The Velocity of the probes delay-lines changes as they heat up and cool down, creating a Zero Point error. PETP mode automatically corrects this problem creating a constant zero that eliminates the need for frequent Probe Zeroing.

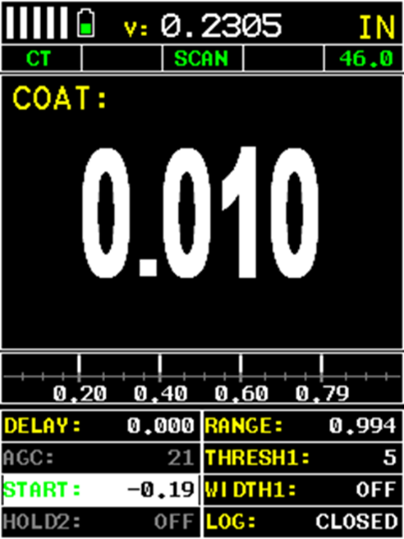

Coating-Only (CT) Mode is a custom hybrid combination mode using special techniques to effectively measure the thickness of coatings.

CMX CT Mode

CMX CT Mode

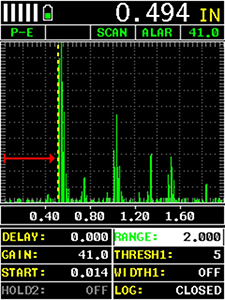

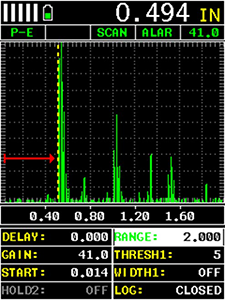

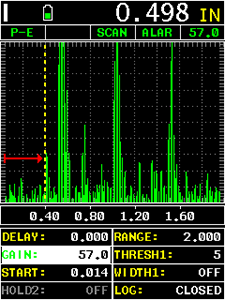

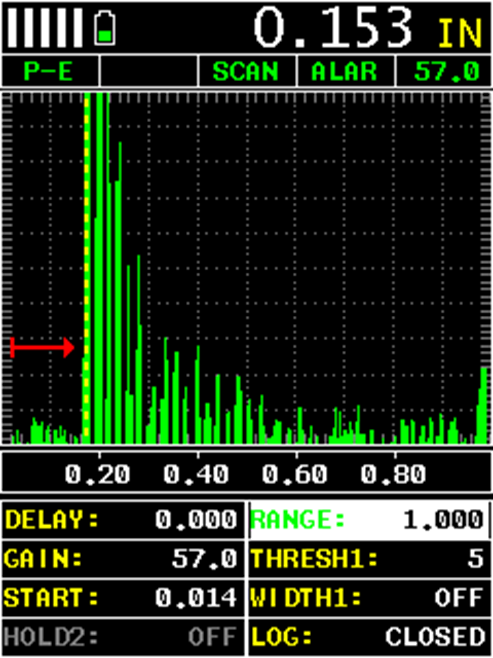

A-Scan shows the signal that is being measured.

Strong Back Wall Echo and Multiple Echo

Strong Back Wall Echo and Multiple Echo

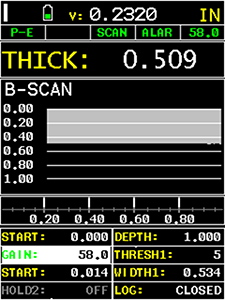

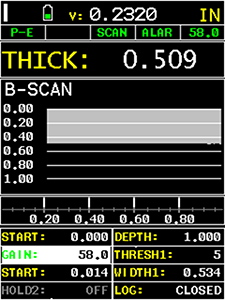

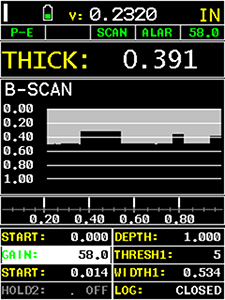

B-Scan graphs a series of measurements. This results in a profile view that is helpful to understand if the material has a single or series of pits, general corrosion, inclusion or lamination.

Consistent Back Wall Echo

Consistent Back Wall Echo

The CMX Series' digital display is simple, direct reading, and can add min/max.

Digital Display with Min & Max

Digital Display with Min & Max

| A-Scan | B-Scan | ||

| Pitted material will show a signal coming before the Back-Wall Echo and a diminished or non-existent the Back Wall Echo, depth measurement will be inconsistent and vary point to point |  |

B-Scan showing various irregular thicknesses |  |

| An inclusion will show a signal coming before the Back Wall Echo but the Back Wall Echo is unaffected. |  |

B-Scan shows inclusions at consistent depth (plateau) |  |

| A lamination usually at mid-wall and of consistent depth |  |

B-Scan showing a plateau of considerable length |  |