| Testing Index |

| Attenuator Error |

Every 20dB ± 1dB |

| Time Base Linearity |

≤0.5% |

| Amplitude |

≤ ± 2% |

| Pulser |

| PRF |

Single / dual-element probe channels: 20-1000Hz |

| Matrix Channels: 20-3000Hz |

| Damping |

200 / 1000Ω, 2 levels |

| Receiver |

| Reject |

0-90%, step 1% |

| Gain |

0~110dB, step 0.5/1/2/6/12dB |

| Detection Range |

0-13000mm; min. display range: 5mm; min. step: 0.1mm |

| Pulse Shift Range |

-25~10000mm, min. step 0.1mm |

| Auxiliary Function |

Coordinate switch (sound path/depth/horizontal), freeze, auto gain (40-100%, step:10%), peak envelop, wave compare, zoom, gate expansion, screenshot, cineloop, wave filling, rail type selection (38/43/50/60/70 kg/m), weld I-shape mark (auto/manual), B-Scan image, GPS, camera record, WIFI. |

| Material Velocity |

200~20000m/s, min. step 1m/s |

| Probe Zero |

0-1000 us, min. step 0.01m/s |

| Calibration |

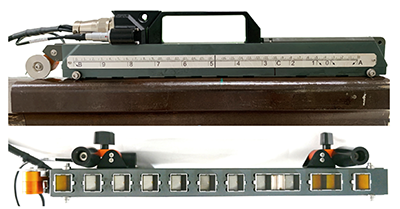

Velocity and Zero; Probe angle, Encoder |

| Curve Function |

Single/dual-element probe channels: DAC, PAC |

| Matrix channels: Sensitivity compensation curve |

| Gate |

| Gate |

Gate Start: -25~13000mm, min. step 0.1mm |

| Gate Width: 0.1-13000mm, min. step 0.1mm |

| Gate Thresh: 10-90% (step 1%) |

| General Specifications |

| Display Screen |

5.7" high brightness TFT LCD 640x480 pixels |

| Dimensions |

6.34" x 9.8" x 4.1" (161 x 248 x 103 mm) |

| Weight |

Approx. 4.2 lbs. (1.9kg) (including battery) |

| Language |

English |

| Peripheral Port |

2 USB ports, SIM card port, Ethernet port |

| Encoder Connector |

1 pc. (4-core) |

| Battery Operating Time |

≥ 8hrs. |

| Internal Storage |

16GB; 500 data sets |

| Power Supply |

DC 12V (external power supply); 7.4V (battery) |

| Operating Temperature |

-13° ~ 122°F (-25° ~ 50°C) |

| Storage Temperature |

-4° ~ 140°F (-20° ~ 60°C) |

| Certifications |

ISO22232-1 |