The ETS2-77 is intended for the mechanized inspection of rails and switches as well as confirmation of the results of a grinding application. The device is capable of testing a wide range of rail profiles. The eddy current technology enables localizing the following surface defects:

The eddy current rail inspection equipment ETS2-77 is capable of evaluating the vertical depth of the defect, thus allowing a more efficient management of rail defects. The inspector can easily decide on the defect removal method: grinding, milling or re-railing, which saves time and money.

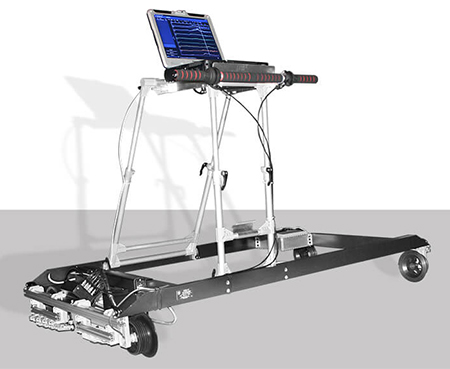

The ETS2-77 flaw detector can be folded for transportation or assembled

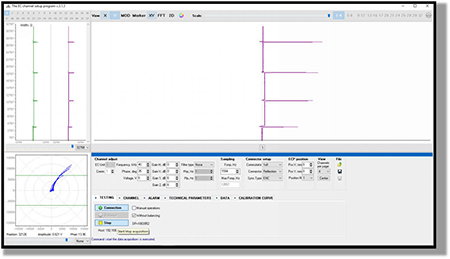

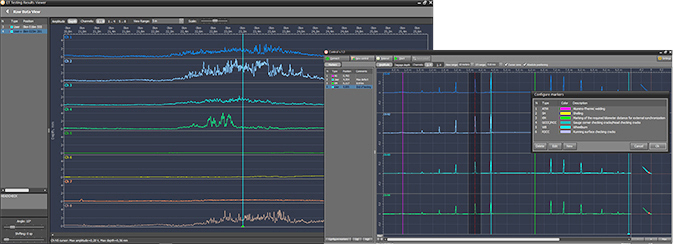

Eddy Current Channel Setup

Testing

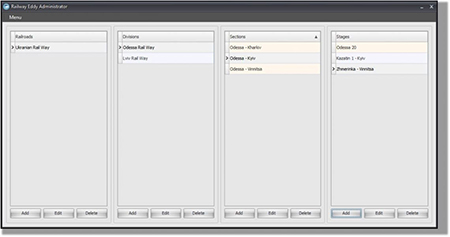

Generating Railroad Names

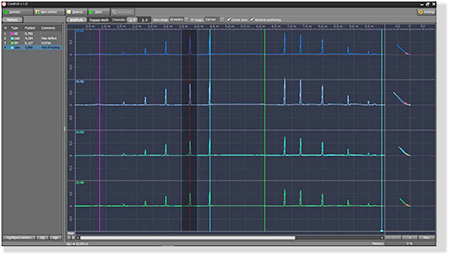

The specialized software contains four main parts:

Review Test Results

| Model | ETS2-77 |

| Flaw Detector Type | Mechanized |

| Dimensions | In Stowed Position: 1730 mm × 900 mm × 350 mm |

| Eddy Current Channel | Eddycon D |

| Scanning Device | Scanner of the gauge face of the rail Scanner of the rolling surface control |

| ECP Quantity | 8 |

| Tested Area by 1 ECP | 6 mm |

| ECP Protection | Ceramic protective cover for protection from abrasion and damage |

| Test Velocity | Up to 2 m/s |

| Alarm | Visual |

| Specialized Software | Setup program Test program Results review program |

| Operating Time | 8 hours |

| Record and Data Storage | + PC hard disk |

| Working PC | Industrial, IP rating 65 |

For more information, please contact us