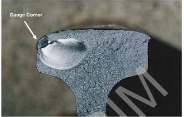

The AREMA CODE requires that ultrasonic rail flaw detectors have the capability of detecting VSH (Vertical Split Head) defects. This requires 11 probes/channels. The two additional probe/channels make AREMA compliant models a bit more expensive than 9 probe systems which do not have the capability to detect VSH type flaws. We offer 9 probe systems to those customers that are not concerned with VSH type flaws.

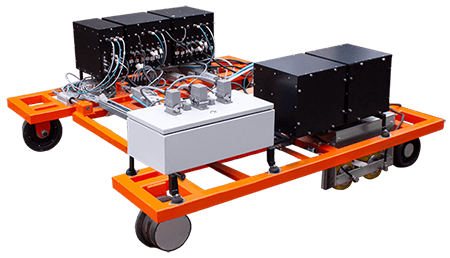

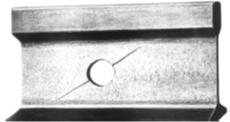

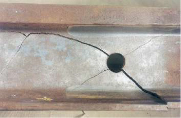

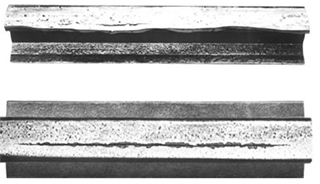

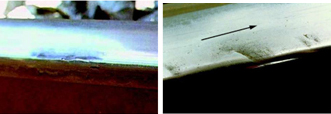

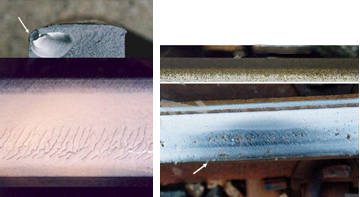

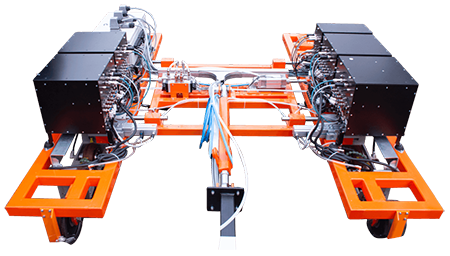

The OKOndt OKOSCAN 73HS System is designed for automated high-speed testing of rails in service. This ultrasonic rail inspection equipment detects all types of critical defects: transverse, longitudinal and horizontal cracks, cracks from bolt holes, etc. This system can ensure testing at speeds up to 40 km/hr. (25 miles/hr.) with test results displayed in the form of A- and B-Scans. Features 4 wheel-type ultrasonic probe units, couplant supply system, specialized software and rugged batteries that supply 8 hours of continuous use.

The testing trolley assures the positioning and movement of the wheel probes. Electric drives mounted onto the trolley automatically adjust the trolley to the track width. It is an auxiliary mechanism that centers the wheel probes along the rail axis.

Key Features

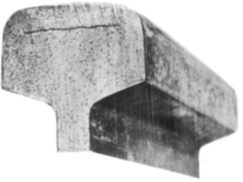

The ultrasonic rail testing system incorporates four (4) wheel probes. Each probe includes:

70° Probes

45° Probes

0° Probes

40° Side Looking Probes

58° x 34° Probes

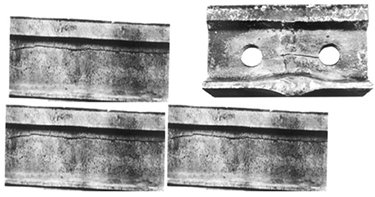

The OKOndt OKOSCAN 73HS System utilizes OKO-24 single-channel ultrasonic modules with a frequency range from 1 to 7 MHz and initial pulse sending frequency of up to 4kHz.

The 73HS structure envisages two positioning options of the ultrasonic modules:

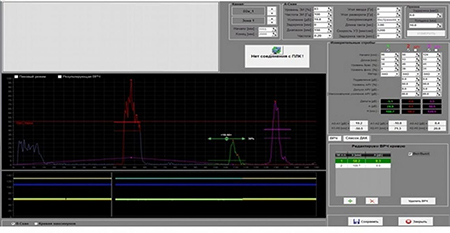

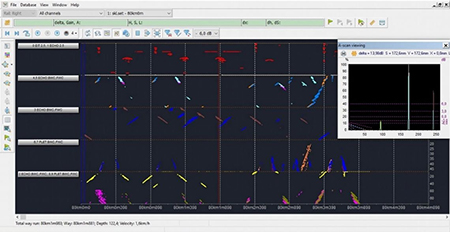

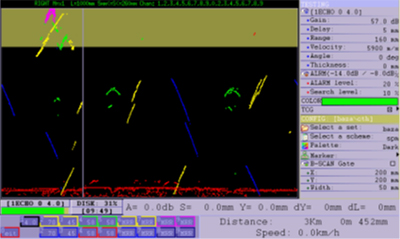

The OKOndt OKOSCAN 73HS high-speed rail flaw detector is supplied with pre-installed software. The software is composed of:

Wheel Probe Positioning (left), Example of Testing Mode Display (right)

Couplant Supply System

The system consists of the tank, program-controlled pump, check valves and regulating valves. At movement, the couplant is automatically supplied under the ultrasonic wheels, meanwhile the water flaw is automatically adjusted depending on the speed of movement.

System Power Supply

Power supply of all the system’s equipment is ensured by the rugged batteries, with the capacity for continuous operation of the system for 8 hours.

Positioning System

Positioning system consists of an Encoder and a GPS module. The Encoder precisely determines the travelled distance and binds the received testing data and the set position marks to the travel coordinate. The GPS module ensures continuous recording of the cart’s geographic coordinates, as well as coordinates of the detected flaws.

For more information, please contact us