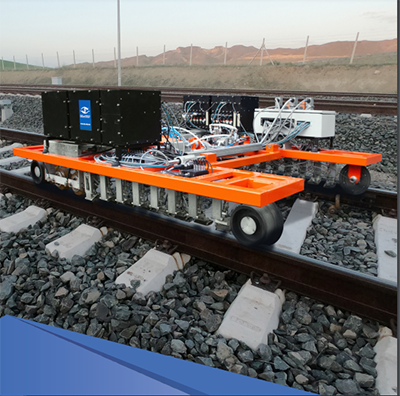

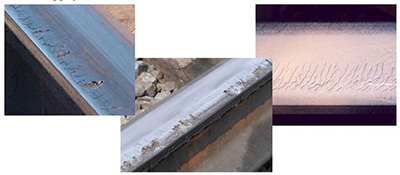

The OKOndt OKOSCAN ET-73HS System is designed for automated high-speed eddy current testing of the working service of the rail head and of the rail edge. The OKOSCAN ET-HS System detects all types of critical defects: transverse fatigue cracks and headchecks, quench cracks and wheel slippage areas and can ensure testing at speeds up to 40 km/hr. (25 miles/hr.) with test results saved on the database. Features 2 Eddycon D eddy-current flaw detectors, sixteen eddy-current (probes) (ECP) - eight for each rail, a track gauge and specialized software.

The trolley is a steel support structure with wheels, alignment system (pneumatics), lifting and lowering mechanism (electronic monorail hoist) and positioning system eddy current probes. The trolley provides accurate positioning and movement of the eddy current probes. Pneumatic equipment mounted to the trolley is used for automatic adjustment of the trolley to the track width and ensures positioning of each probe on its own testing area.

Key Features

The OKOSCAN ET-73HS is equipped with 16 eddy current probes (ECP) - 8 for reach rail.

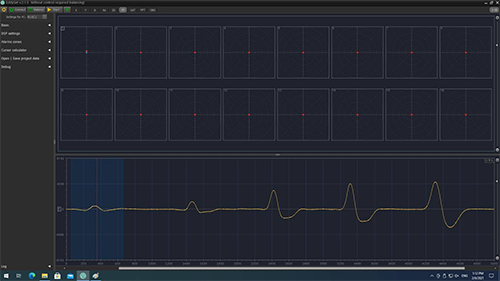

The OKOSCAN ET-73HS is supplied with pre-installed software that consists of:

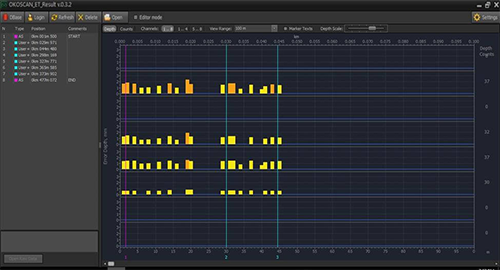

Software for control and analysis of the current data

Software for viewing the testing results

| Parameters of the defect detection efficiency | |

| Tested Area for each rail | 5 ECP - running rail surface 3 ECP - rail working edge |

| Positional Accuracy | Longitudinal coordinate: ± 5 m/km |

| Eddy current equipment vertical depth evaluation | from 0.5mm to 3mm |

| GPS | Recording the global positioning coordinate in the control file and then viewing it on a computer |

| Defect depth evaluation accuracy 0 - 0.5mm 0.5 - 1.5mm 1.5 - 3mm |

± 0.3 mm ± 0.5 mm ± 0.7 mm |

| General Specifications | |

| System Configuration | Each Eddycon D module is capable of processing the signals from ECPs (to receive required testing speed – 40 km/h). Number of ECPs and System configuration depends on the Customer’s specific requirements. |

| Quantity of Probes & Modules | 1 Eddycon D module per rail 8 ECPs per rail |

| Measuring Step | 1 measure per 1 mm |

| Testing Speed | up to 40 km/h – with a testing step of 1mm |

| Types of tested rails | S49 (49E1), UIC54 (54E1), UIC60 (60E1) |

| Communication between PC and PLC | Ethernet |

| Path Measurement Parameters | |

| Resolution along the travel path | 1mm |

| Positional accuracy | ±3 m per 1000 m |

| Encoder type | magnetic, incremental |

| Encoder calibration | adjustable |

| Power Supply System Parameters | |

| Voltage Input | 12V |

| Power Consumption | Up to 1kW (all equipment working) |

To purchase the OKOndt ET-73HS Eddy Current Rail Testing System, please contact us.