| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt UDS2-77 SC Trolley Ultrasonic Single Rail Flaw Detector for Tram Rails | UT-OKO-UDS2-77-SC-Trolley |

|

Request Pricing | ||

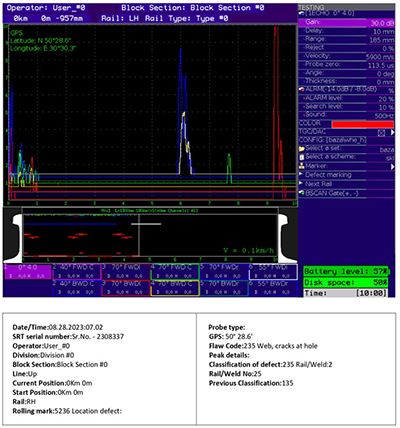

The UDS2-77 SC Trolley ultrasonic rail flaw detector is a manually propelled cart designed for inspection of streetcar lines with rails of standard or "groove" type profile. The UDS2-77 SC Trolley modular structure includes a frame on rollers, a central electronic unit and multiplexer units. The rail flaw detector allows you to test the entire section of the rail, with the exception of the sole flanges and the groove limiter, using the pulse-echo, echo-shadow and echo-image methods. 100% high quality testing of the rail is provided at a scanning speed of up to 3 mph (5 km/h) which corresponds to the average walking speed of a person. The design of the UDS2-77 SC Trolley’s alignment and adjustment systems enables testing of rails differing in geometry and dimensions – with a single flaw detector.

The user has access to 3 types of quick reports generated from the device menu, plus four analytical reports that are generated on a remote workstation using OKO's "Rail Inspector" software. Each report includes:

UT techniques: pulse echo, (echo image) and echo shadow.

Number of ultrasonic channels for 100% scanning: 11.

Nominal test frequency: 1 to 6 MHz.

Distance between probe pulse sendings: 2,5 mm at motion speed up to 5 km/h.

Variation range of receiving path gain: 0 to 100 dB, with a step of 1 dB.

Memory capacity for data storage: not less than 16 Gb.

Weight of the flaw detector without couplant: up to 20,5 kg.

The flaw detector is powered by an independent power source (battery) with the rated voltage 12V and rated capacity of no less than 18 А·h.

Time of operating mode setup: up to 15 sec.

Time of continuous operation of the flaw detector with a fully-charged battery: no less than 8 hours.

Protection rating: IP 64.

The following alarms are generated during flaw detection: light – common via all test channels; sound – common for a group of channels; visual, on the screen – separate for every channel.

GPS system is used to determine defect location coordinates on the track.

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt UDS2-77 SC Trolley Ultrasonic Single Rail Flaw Detector for Tram Rails | UT-OKO-UDS2-77-SC-Trolley |

|

Request Pricing | ||