| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt UDS2-77 AREMA Compliant Ultrasonic Single Rail Flaw Detector, SL and RSU Models | UT-OKO-UDS2-77-AREMA |

|

Request Pricing | ||

The AREMA CODE requires that ultrasonic rail flaw detectors have the capability of detecting VSH (Vertical Split Head) defects. This requires 11 probes/channels. The two additional probe/channels make AREMA compliant models a bit more expensive than 9 probe systems which do not have the capability to detect VSH type flaws. We offer 9 probe systems to those customers that are not concerned with VSH type flaws.

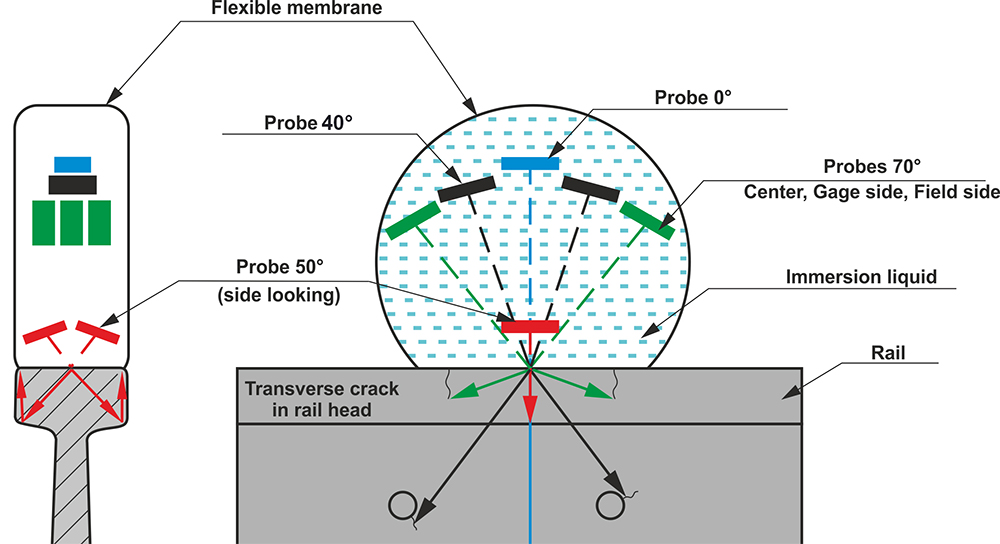

The UDS2-77 AREMA ultrasonic flaw detector is intended for inspection of rails and switches, as well as for quick verification flaws detected by high speed test vehicles results. The detector ensures flaw detection in the entire rail cross section, excluding rail base blades. Complies with AREMA requirements and is available in two versions each with 11 channels: RSU with immersion probe unit design and SL with sliding probe unit design. Includes A-Scan, B-Scan, and A-Scan+B-Scan modes and specialized software for test result analysis and evaluation which can be viewed on the screen of the flaw detector. Designed with light-weight and shock-resistant plastic.

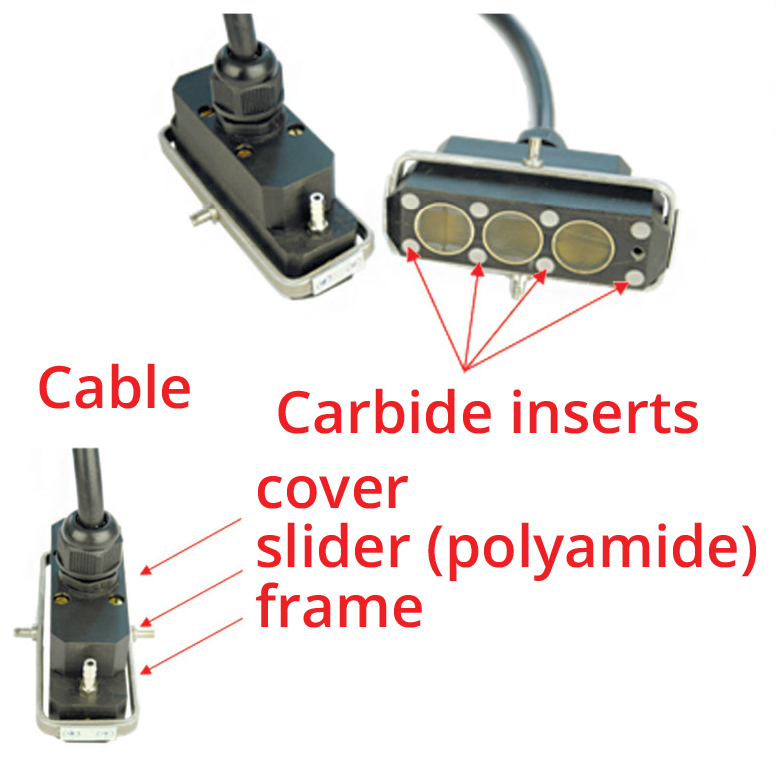

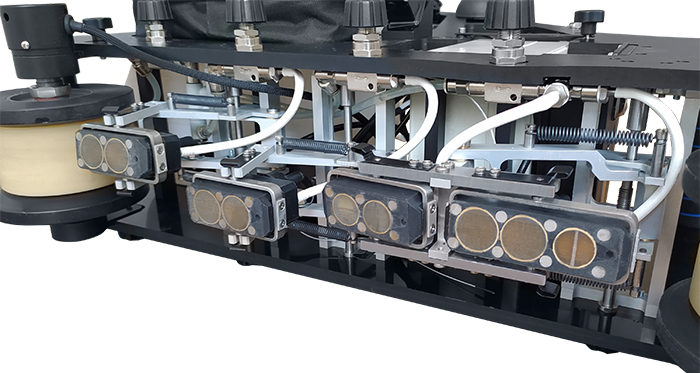

UDS2-77 AREMA SL Units Probe

UDS2-77 AREMA RSU Wheel Probe

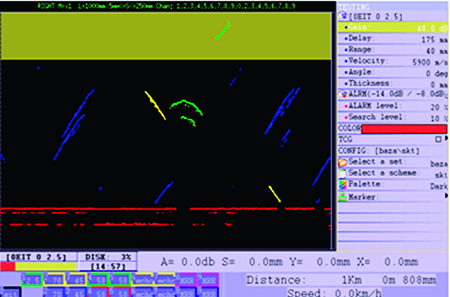

A-Scan for one channel display mode

B-Scan for one channel display mode

The “Rail Inspector” program is intended for display, analysis and evaluation of test results on PC. The program includes all the necessary tools to process data. The major features of the program are:

Main Technical Specifications

| Compliance | AREMA requirements |

| Number of Inspection Channels (Probes) | 11 psc |

| Probe Type & Frequency | 0°/4 MHz, ±70°, ±40/45°, ±50°SL/2 MHz Scanning pitch 1mm at a speed of 4 km/h (2.5m/hr) |

| Display Modes | A-Scan, B-Scan, A-Scan+B-Scan |

| Couplant Tank Volume | 5 l (1.3 gal) |

| Couplant Consumption | Up to 1.5 l/km (0.4 gal), at a speed of 4 km/h (2.5 m/hr) |

UDS2-77 RSU and SL Comparison

|

|

| RSU | SL |

| Immersion probe unit design - wheel (RSU) | Sliding probe unit design (4 sliding blocks) |

| Probes | |

| 0°-4 MHz | 0°-4 MHz |

| 70°-2 MHz (Head Central Forward ) | 70°-2 MHz (Head Central Forward) |

| 70°-2 MHz (Head Central Backward) | 70°-2 MHz (Head Central Backward) |

| 70°-2 MHz (Head Gauge Face Forward) | 70°-2 MHz (Head Gauge Face Forward) |

| 70°-2 MHz (Head Gauge Face Backward) | 70°-2 MHz (Head Gauge Face Backward) |

| 70°-2 MHz (Head Field Face Forward) | 70°-2 MHz (Head Field Face Forward) |

| 70°-2 MHz (Head Field Face Backward) | 70°-2 MHz (Head Field Face Backward) |

| 2 x 40°- 2 MHz (Web, Foot Forward / Backward) | 2 x 45°- 2 MHz (Web, Foot Forward / Backward) |

| 2 x 50°- 2 MHz (Head Side Looking) | 2 x 50°- 2 MHz (Head Side Looking) |

| Specifics of Application/Tester Comparison | |

| Limited to soft tire bumps | Limited to rail level differences of no more than 15 mm (0.6") at rail junctions |

| Requires a strictly vertical position of trolley during rail testing |

Trolley tilt of +/- 15º is acceptable during rail testing |

| Comparison of Costs, Repair and Maintenance | |

| The cost of repair/replacement of the probe unit (RSU) is higher |

The cost of repair/replacement of sliding probe units is lower |

| The cost of soft tire replacement is lower | The cost of sliding probe units replacement is higher |

| The process of soft tire replacement is more difficult |

The process of sliding probes replacement is easier |

| Flaw Detector: Higher Cost | Flaw Detector: Lower Cost |

| Net Weight (Without Liquid) | |

| 23 kg (50.7 lbs.) | 17 kg (37.5 lbs.) |

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt UDS2-77 AREMA Compliant Ultrasonic Single Rail Flaw Detector, SL and RSU Models | UT-OKO-UDS2-77-AREMA |

|

Request Pricing | ||