| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

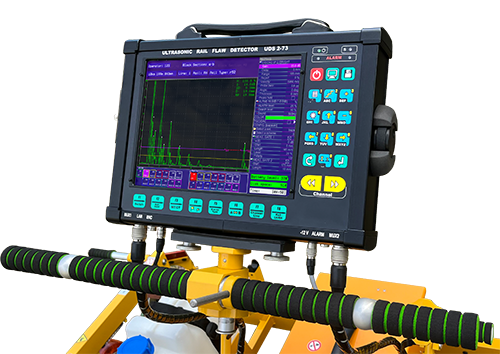

| OKOndt UDS2-73 RSUI Ultrasonic Rail Flaw Detector System with Warning Light Option | UT-OKO-UDS73-RSUI |

|

Request Pricing | ||

The AREMA CODE requires that ultrasonic rail flaw detectors have the capability of detecting VSH (Vertical Split Head) defects. This requires 11 probes/channels. The two additional probe/channels make AREMA compliant models a bit more expensive than 9 probe systems which do not have the capability to detect VSH type flaws. We offer 9 probe systems to those customers that are not concerned with VSH type flaws.

The UDS2-73 RSUI Ultrasonic Rail Flaw Detector is designed for continuous testing of both rails on the rail track including turnouts (crossings, frogs) at a speed of up to 3.3 mph (5 km/h). The UDS2-73 RSUI benefits from a lower weight, more attractive design, use of 6.3" (160 mm) immersion wheel, easy to use mounting adjustment mechanism, foot brake and many other features. The ergonomic, light and reliable design of the trolley ensures testing of all existing rail sizes and defect detection in both rails of the track along the entire length and rail cross-section (except for rail foot flanges). The UDS2-73 RSUI flaw detector ensures testing in compliance with the requirements of IRS 70712:2018 (UIC 712 R), AREMA, EN 16729-1.

| Display | 10" LCD screen - high resolution and high quality |

| Testing Speed | up to 5 km/h |

| Probes | 11 pcs (00/4MHz, ±37, ±70C, ±70GS, ±70NGS, ↑↓55 SL/2 MHz). |

| Working Temperature | -22°F to 122°F (-30°C to 50°) |

| Humidity | 95% |

| Working Time | 12 hrs. continuous with full battery |

| Standards | IRS 70712:2018 (UIC 712 R), EN16729-1, AREMA and EN 13977. |

| Rating (electronic unit) | IP65 according to the EN60529 standard. |

The user has access to 3 types of quick reports generated from the device menu, as well as 4 analytical reports that are generated on a remote workstation on a computer using special software "Rail Inspector".

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| OKOndt UDS2-73 RSUI Ultrasonic Rail Flaw Detector System with Warning Light Option | UT-OKO-UDS73-RSUI |

|

Request Pricing | ||