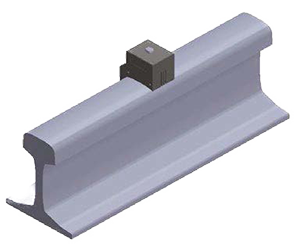

The ETher RailCheck Eddy Current Flaw detector is designed to easily detect and record surface breaking cracks in the head of rails. It combines a hand-held Eddy current flaw detector with a custom probe designed to inspect the running surface of the rail. A special trolley allows the operator to walk the probe down the rail with minimal effort. The specially designed probe allows the field and gauge corners to be inspected together with the rail face. The Eddy current flaw detector can trigger an audible and visual alarm should a defect be detected. The instruments' display shows the presence of potential defects in the rail and the complete inspection is continuously recorded for later analysis.

ETher's widescan are used in conjunction with an with an ETher NDE portable flaw detector for rapid rail inspection. They can detect surface breaking flaws, lightness and overcome consistency problems associated with ultrasonic couplant and higher surface speed capability.

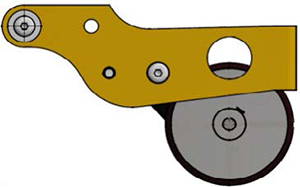

The Rail probe, a single probe that is capable of detecting orientated flaws in one pass of the rail head, giving depth (size) of the flaw.

A rotary encoder to provide distance information to the software and synchronize the sample rate with the speed.

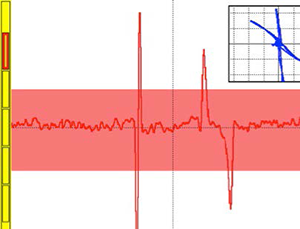

"Trace" vs. "Vector" can be captured and when using Vector Display both data sets can be shown simultaneously.

The Filus EC-1 is straightforward in use. The trolley is hand pushed along the track under test, at a normal walking pace, providing a highly accurate test of the rail surface. The operating parameters remain set for the majority of the operation, the only setup required is calibration against a known size slot in the test piece, then the unit is placed on the rail and the probe block lowered onto the surface. The system is then balanced (an automatic operation to null all readings on a clean section of rail), then the distance counter is reset and recording can start. The display will show data at the current point.

| Probes | Connectors | LEMO 2B 12 way |

| Modes | Absolute, Bridge, Reflections, Conductivity and Rotary 600-3000 rpm ETher Mercury Drive (ARD002). | |

| Frequency | Dual Frequency 10Hz - 12.8MHz | |

| Gain | Overall | -18 to +100 dB, 0.1, 1 and 6dB steps (100dB Max) |

| Input | 0dB or 12dB | |

| Drive | 0dB, 6dB and 10dB (0dB ref 1mW into 50Ω) | |

| Max X/Y Ratio | +100dB | |

| Phase | Range | 0.0° – 359.9°, 0.1° steps |

| Auto-Phase | Allows phase angle to be automatically set to a pre-set angle | |

| Filters | Normal High Pass | DC to 2kHz or Low Pass Filter, whichever is the lower in 1 Hz steps. Plus variable adaptive balance drift compensation 0.01 - 0.5 Hz (6 steps). |

| Normal Low Pass | 1Hz to 2kHz or a quarter of the lowest test frequency, whichever is lower in 1 Hz steps. | |

| Balance | Manual | 4 internal balance loads; 2.2μH, 5.0μH, 6.0μH, 6.5μH, 7.0μH, 7.5μH, 8.2μH, 12μH, 15μH, 18μH, 22μH, 30μH, 47μH, 82μH |

| Automatic | Optimized balance load selection | |

| Alarms | Box | Fully configurable, Freeze, Tone or visual |

| Sector | Fully configurable, Freeze, Tone or visual | |

| Output | Open collector transistor (25v dc at 10mA max) | |

| Display | Type | 5.7” (145mm), 18-bit Colour, daylight readable |

| Viewable Area | 115.2mm x 86.4mm (Horizontal x Vertical) | |

| Resolution | 640 x 480 pixels | |

| Flip | Manual or automatic screen orientation change to enable left or right-handed use. | |

| Color Schemes | User configurable Dark, Bright and Black & White | |

| Configurable Screen | Full Screen, Single, Dual Spot or Dual Pane with variable size and location. Screen and function e.g. XY, Timebase, Waterfall and Meter | |

| Display Modes | Spot, Time base (0.1-20 seconds x 1-200 sweeps and up to 55 seconds), Waterfall and Meter with peak hold and % readout | |

| Graticule | None, Grid (4 sizes 5, 10, 15 and 20% FSH), Polar (4 sizes 5, 10, 15 and 20% FSH) | |

| Offset | Spot Position: Y =-50 to +50, X =-65 to +65% | |

| Digital Spot | Display in X, Y or R,θ | |

| Position Readout | Display of all settings in Legacy Format | |

| Removable Data Storage | Setup Storage | micro SD up to 32GB, holding over 10,000 settings |

| Stored Screen Shots | micro SD up to 32GB, holding over 10,000 screen shots | |

| Record Replay | Comprehensive Record Replay and Storage. Real-time recording of trace data and Replay on instruments and desktop PC up to 200km max per 2GB file. |

|

| Outputs | PC Connectivity | USB (Full PC remote control plus Real Time data) |

| Digital Alarm | On Lemo 12-way Open collector transistor (25v dc at 10mA max). | |

| VGA | Full 15-way VGA output | |

| Languages | English, French, Spanish, Russian, Japanese, Chinese, Turkish. | |

| Power | External | 100-240 v 50-60Hz 30 Watts |

| Battery | Internal 7.2V nominal @ 3100mAh = 22.32 watt.hr | |

| Running Time | Up to 8 hours with a 2MHz Pencil Probe 30% Back Light | |

| Charging Time | 2.5 hrs. charge time, Simultaneous charge and operation |

| Dimensions (depending on gauge and probe configurations) | ||

| Length | Unit Stowed: 35" (889mm) | Operational above rail top: 26.2" (664mm) |

| Width | 9.8" (249mm) | |

| Height | Unit stowed: 12.9" (327mm) | Operational above rail top: 38" (963 mm) |

| Total mass in operating regime | 21 lbs. (9.5 kg) | |

To purchase a RailCheck, click on the link below