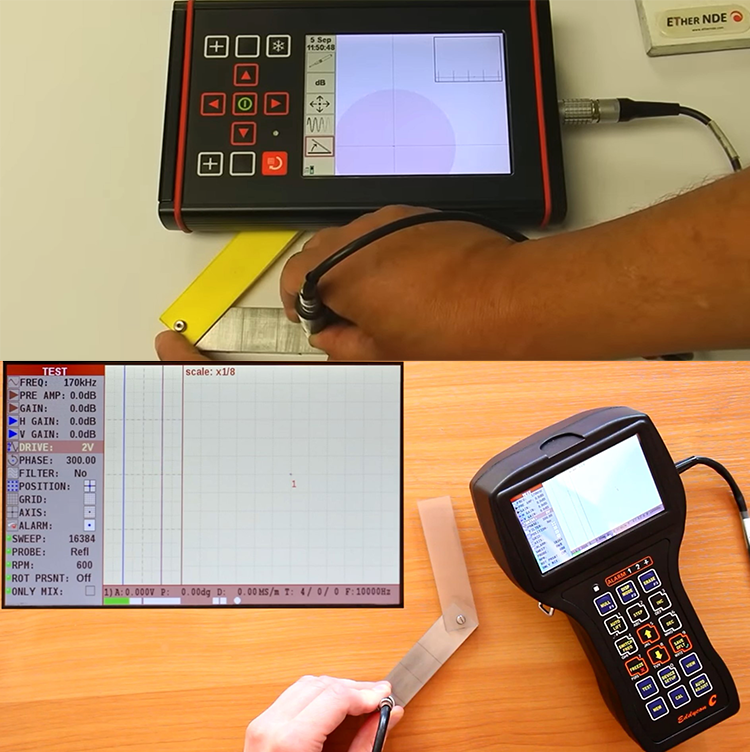

Eddy Current Weld Testing Equipment is used across a broad scope of industries that include pipeline, oil & gas, building, and rail. The variety of equipment available can be difficult to navigate; and the scope of supply for each purchase is not always in proportion with the needs of the application. The purpose of this guide is to illustrate the primary industries of application so that each end user of Eddy Current Equipment can make an informed choice for their Weld Inspection Equipment.

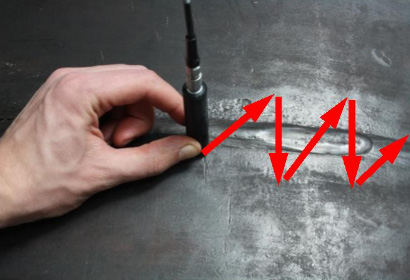

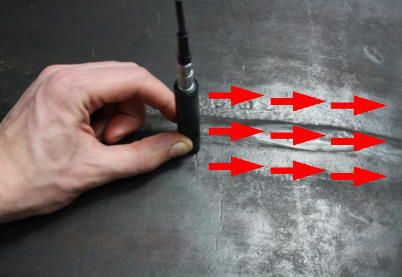

In Construction and Structure Welds, Eddy Current is advantageous in detecting surface cracks on welds whose sudden expansion would lead to catastrophic failure. Typical Probes in these applications are generalized and require little specialization.

In Construction and Structure Welds, Eddy Current is advantageous in detecting surface cracks on welds whose sudden expansion would lead to catastrophic failure. Typical Probes in these applications are generalized and require little specialization.

Oil & Gas Offshore Rig Welds require Eddy Current Inspection to detect cracks that would result in catastrophic failure of the rig structure. Probes are generalized here, too. And of specific interest is highly portable Eddy Current Inspection Equipment.

Oil & Gas Offshore Rig Welds require Eddy Current Inspection to detect cracks that would result in catastrophic failure of the rig structure. Probes are generalized here, too. And of specific interest is highly portable Eddy Current Inspection Equipment.

For Bridges Welds, Eddy Current is applied to detect surface-breaking cracks on microstructural, heat-affected areas. Also of concern is corrosion on the weld. Special Probes are desired for inspections in this type of application.

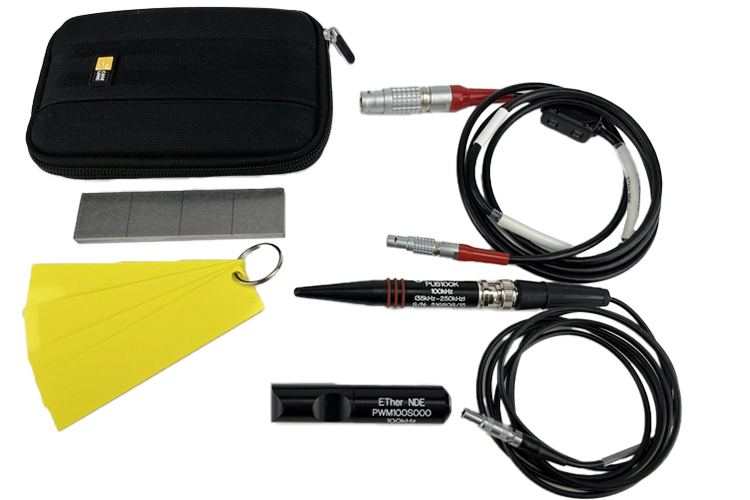

For Pipeline Welds, Eddy Current Inspection reveals stress corrosion cracking and pitting that is typical in the field. More often than not, it is necessary to measure the coating thickness on the pipe with specialized Paint-and-Lacquer Coating (PLC) Probes.

For Pipeline Welds, Eddy Current Inspection reveals stress corrosion cracking and pitting that is typical in the field. More often than not, it is necessary to measure the coating thickness on the pipe with specialized Paint-and-Lacquer Coating (PLC) Probes.

Other methods for inspecting welds for surface and sub-surface cracks include Magnetic Particle Inspection and Penetrant Inspection. Both methods require the use of consumables which can be time consuming and messy. However, Eddy Current Weld Inspection requires no consumables or surface preparation. Other advantages include: