The LD 3000 AF Automatic Hardness Tester for Case Hardness Depth (CHD) + Rockwell Hardness. Made to quickly determine the Case Hardness Depth (CHD) from 0.005" to 0.8" (0.12 mm to 2 mm). There is no need to destroy the specimen or separate material types before performing the test. With just one measurement it reduces CHD hardness testing time and costs compared to traditional polished cross sections using of Vickers and Knoop methods. The LD 3000 AF is entirely motorized and it is equipped with a wide touchscreen for ease in test planning and a clear view of results.

How it Works:

Load forces are applied through load cells and electronically controlled in Closed Loop (Pat. Affri). Statistics and Case Hardness Depth (CHD) charts are automatically generated and can be stored with the test session in the large archive. It also features a user friendly interface with conversion tables and round correction values for tests on convex cylindrical surfaces of various diameters. Complies with ASTM and ISO hardness standards.

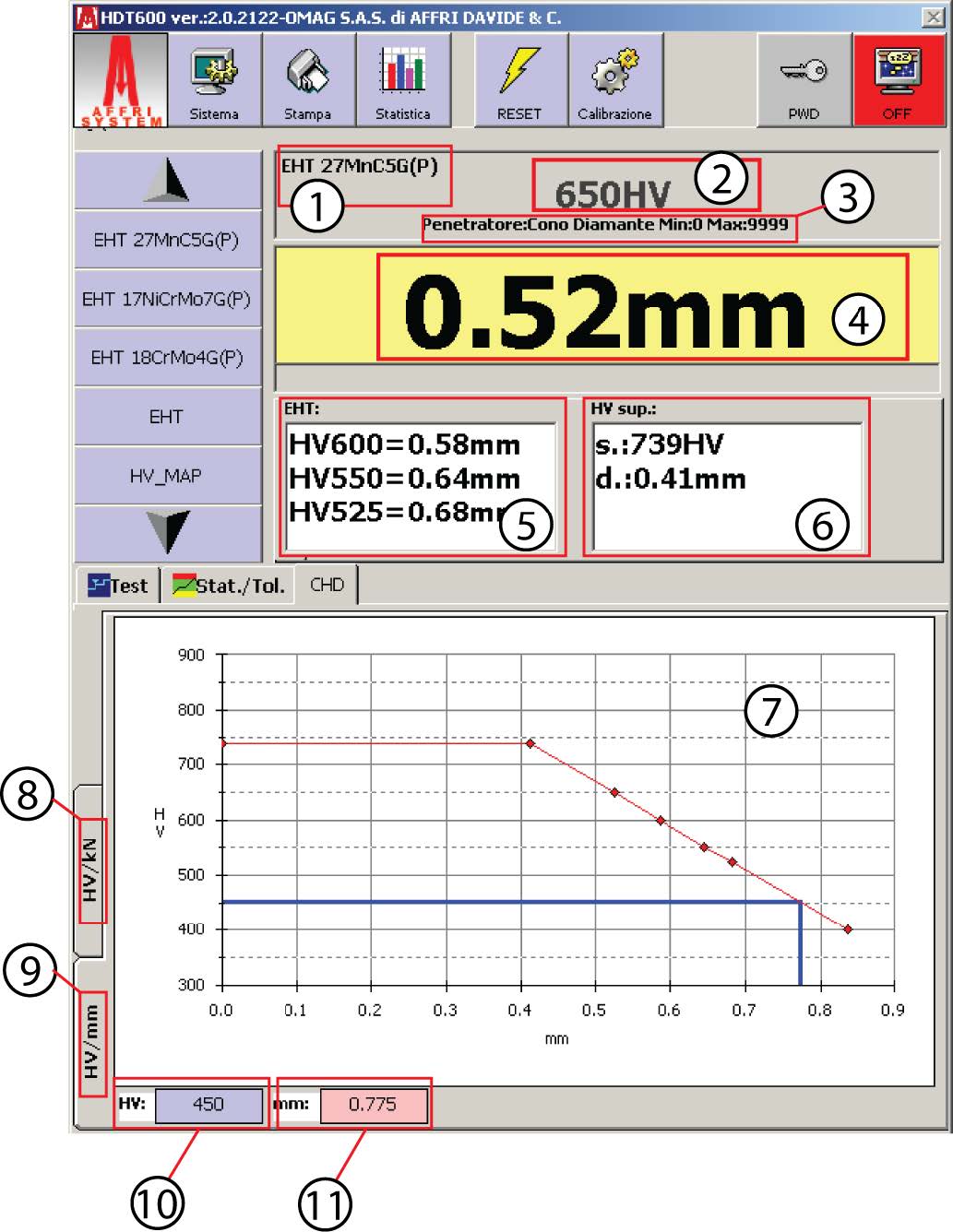

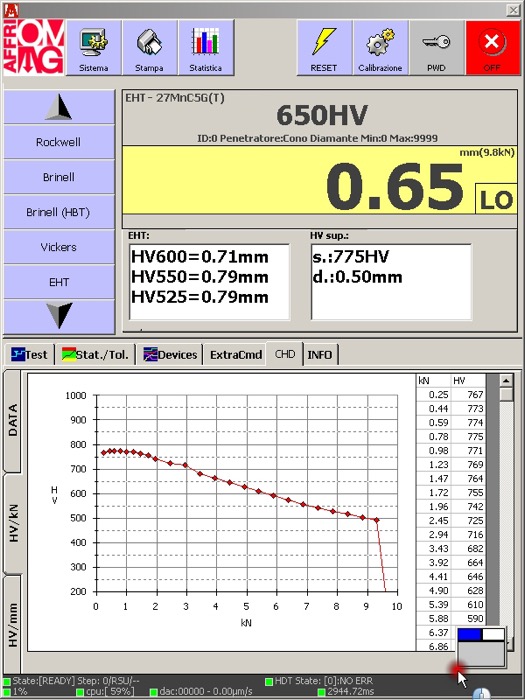

The following numbers refer to the graph on the right

HDTL Method

Measures the definition of the superficial hardness and its effective Case Hardness Depth (CHD) from 0.005" to 0.8" (0.12 to 2 mm). The LD 3000 AF will determine the Case Hardness Depth(CHD) (with great precision and minimal operator intervention) on finished products, without destroying the specimen and without the random sampling of manufactured products. There's no need for sample preparation, no need to separate material types or to polish the cross section as in the Vickers method. In just one minute, the tester generates the report with the Case Hardness Depth (CHD) graph.

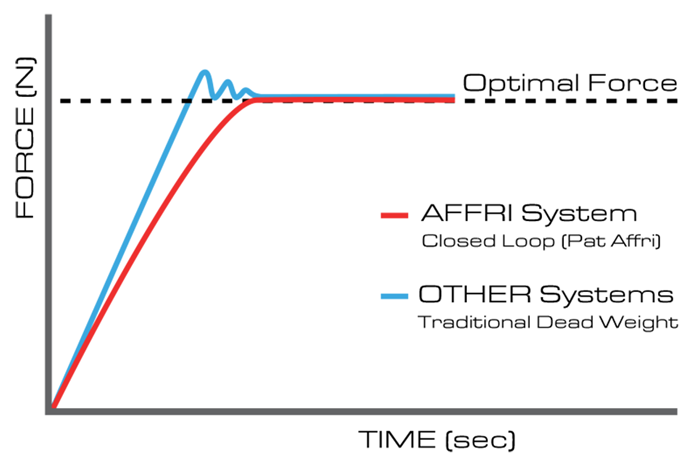

Closed Loop (Pat. Affri)

The force by load cell and the Closed Loop AFFRI system assures absolute accuracy on all test conditions. Closed Loop load cells manage load forces, which are automatically programmed and controlled at each test assuring perfect linearity in every range eliminating the problems associated with dead weight systems on traditional testers. Results are not affected by any structural deflection, misalignment or vibration. The system can also operate in an inclined position.

Easy and Fast Automatic Measurements

Spin the leveling screw handle until the sample makes contact with the clamping hood blocking the piece. Press the START button and the measuring head will approach the specimen, apply the load to perform the indentation and goes back upward; all in automatic succession without breaching a phase. When testing unstable samples or deflective parts, the AFFRI System will follow the sample and not lose contact, compensating any frame deflection during the test cycle. Accurate results are assured even with oiled, dusty or dirty pieces.

| Affri LD 3000 AF Specifications | |

| Standards | EN-ISO 6508 / EN-ISO 14577 / ASTM E-18 / ASTM E-384 |

| Indenter and Clamping-Hood Stroke | 1.25" (30 mm) |

| Elevating Screw Stroke | 0 / 6" (0 / 150 mm) |

| Depth Capacity | 7.5" (190 mm) |

| Test Loads |

Vickers: 98.07 - 147.1 - 294.2 - 490.35 - 980.7 N (10 - 15 - 30 - 50 - 100 kgf) Brinell: 98.07 - 153.2 - 294.2 - 306.5 - 612.9 - 1839 - 2450 - 4900 - 7350 - 9807 N (29403 N on request) (10 - 15.6 - 30 - 31.2 - 62.5 - 187.5 - 250 - 500 - 750 - 1000 kgf) (3000 kgf on request) Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf) Superficial Rockwell: 147.1 - 294.2 - 441.3 N (15 - 30 - 45 kgf) |

| Feasible Tests |

HDTL con curva CHD: 525 - 550 - 600 - 650 (More on request) Vickers: HV10 - HV15 - HV30 - HV50 - HV100 Brinell HBWT: HB30 - HB10 - HB5 - HB2.5 MPa (F/D2) Rockwell: HRA - HRB - HRC - HRD - HRE - HRF - HRG - HRH - HRK Superficial Rockwell: HRN - HRT |

| Load Accuracy | Better than 0.05% |