The Affri LD 3000 AX is an automatic universal hardness tester for Vickers, Rockwell, Superficial Rockwell and Brinell hardness test methods in compliance with ASTM and ISO hardness standards. It features a 360° Swivel Turret with 9 positions, allowing the user to switch between the 4 indenters, 4 optic lenses and 1 milling probe more quickly and easier than ever before. On top of that, the user-friendly touchscreen interface grants quick access to a plethora of automatic functions, such as Auto-Contact, Auto-Clamping, Auto-Indenting, Auto-Switching with Auto-Focus and Auto-Measure, all with the push of a button.

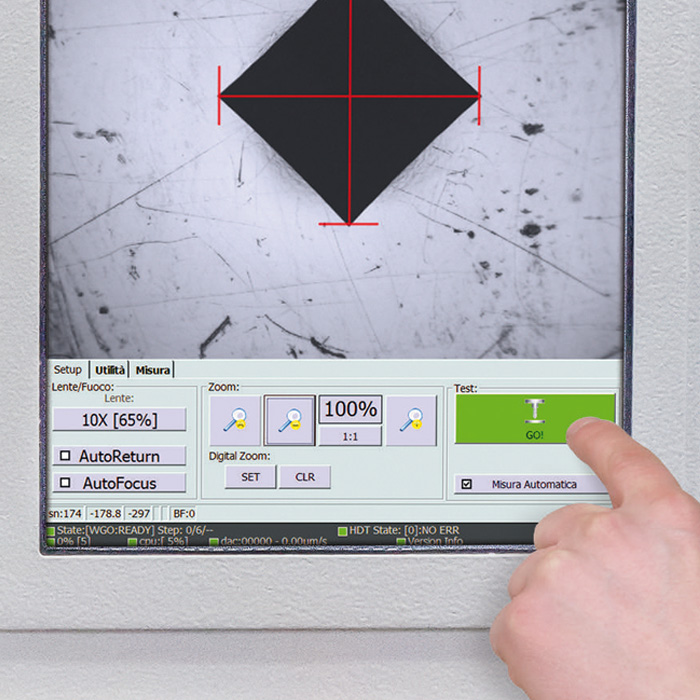

One Button Hardness Measurement

A plethora of automatic functions are accessible through the LD 3000 AX's user interface using the 15" touchscreen. For example, for Auto-Contact, the hardness tester measuring head moves down until contact is made, applies the force and makes the indentation. The software will move to the camera view mode where the indent is automatically measured.

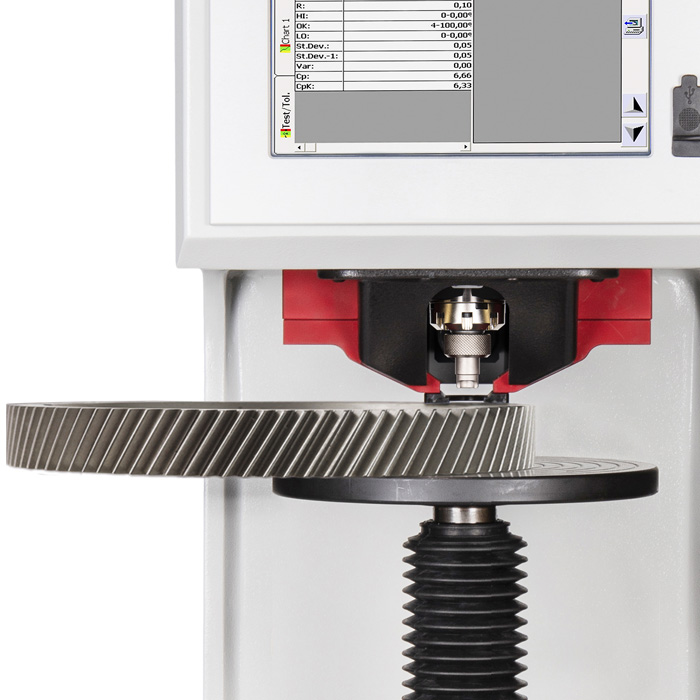

Motorized Turret & Measuring Heads

Each of the 9 positions features a measuring head that makes automated movements. These movements are made with automatic loading when contact is made. The approach of the head to the sample (and not the other way around) makes for more accurate, stable and safe measurements. Additionally, there is one slot for an indenter and one slot for an objective. Auto-Rotate and Auto-Switch functions make complete measurement cycles a breeze.

Patented Affri Clamping System

Secure contact with the specimen is always maintained, even in the unlikely event of a specimen moving during the operation cycle. The clamping system assures perfect stability of any test piece throughout the cycle, and can support more than 4,000 lbs.

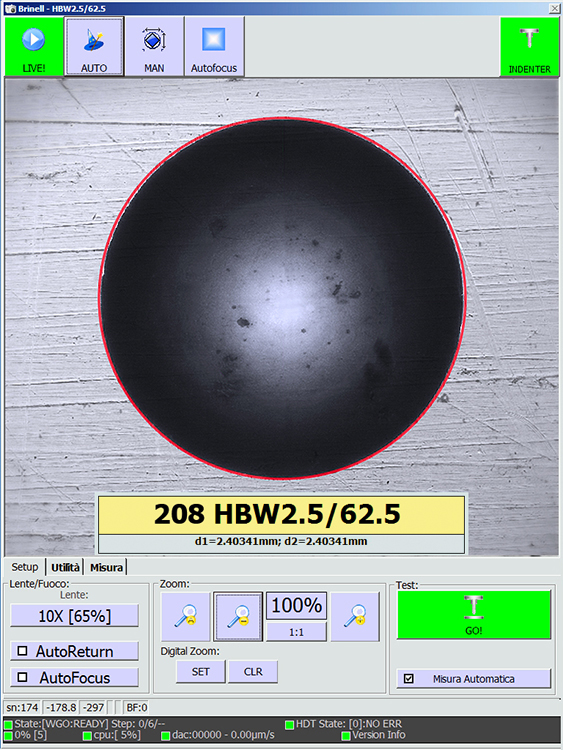

LD 3000 AX Software

The software for the Affri LD 3000 AX comes pre-installed and controls the whole instrument, avoiding setting errors or operator mistakes. This powerful software package is for test cycle managing and automatic indent reading. A wide array of settings and parameters can be set, including measurement setup, image adjustments, statistics, data storage and more, all to ensure that whatever your application, the LD 3000 AX will get the job done.

| Conformity Standards | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / EN-ISO 2039 / ISO 868 / ASTM-E10 / ASTM-E18 / ASTM-E103 / ASTM 2240 / ASTM-E384 / JIS |

| Load Accuracy | Better than 0.05 % |

| Readout Division | 0.1 HBW / HBWT / HV - 0.01 HR |

| Lighting and Objectives | LED - Objectives for HB - HV - HK measurements |

| Focus and Reading | Automatic and Manual |

| Dwell Time | From 1 to 99 seconds |

| Indenter Stroke | Motorized 0.8” / 20 mm |

| Height Capacity | 7.8" - 9.4” / 200 - 240 mm (More on request) |

| Depth Capacity | 7.4" / 190 mm |

| Tolerable Weight | ~4409 lbs (2000 kg) |

| Temperature Range | 50° - 95° F (10° - 35° C) |

| Data Output | USB - Ethernet (RS 232C, wireless upon request) |

| Power Supply | 110 or 220 V / 50/60 Hz |

| Software | Affri - OMAG |

| Principle of Operation | Load Cell and Closed Loop (Affri patent) |

| Applications | For all metals: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys. Heat treatment, hardening, nitriding, cementation and hardfacing. Hard and soft plastics. |

| Shipping Weight | ~1323 lbs (600 kg) |

| Shipping Dimensions | 44" x 43" x 70” (110 x 108 x 174 cm) |